Do you ever find yourself pondering the meaning behind the many colors on your PCB? Or are you undecided regarding the color of the printed circuit board (PCB) that you should use for your circuit board? The answers to these questions can be found in the article that you are currently reading.

We’ll also learn more about the potential issues you’ll encounter with the PCB colors you choose. By the end of this essay, you will understand the best way to customize, purchase, and design the best PCB. With a clear explanation of all the major aspects that influence the value of PCB colors, you can be certain of which PCB color to choose and get the most bang for your buck.

PCB Color: Roles

In order to have an in-depth comprehension of the different colors that can be found on circuit boards, we need to be aware of the fact that the PCB pigmentation that is visible is not the initial board’s actual color. Every color of circuit board is caused by the color of the solder mask, which serves to protect the naked copper wires on the circuit board.

The hue of the solder mask or solder oil is determined by the color of the PCB. It consists of lacquer impregnated with pigments known for their ability to protect copper traces.

Regardless of the solder mask oil or color you select, it should have a high contrast with the copper wires on the circuit board, allowing for easy identification. The copper wires are given some protection from short-circuiting by this colored coating. Also, it provides a layer of protection against potential damage to the board from wear and strain.

Type of PCB Colors

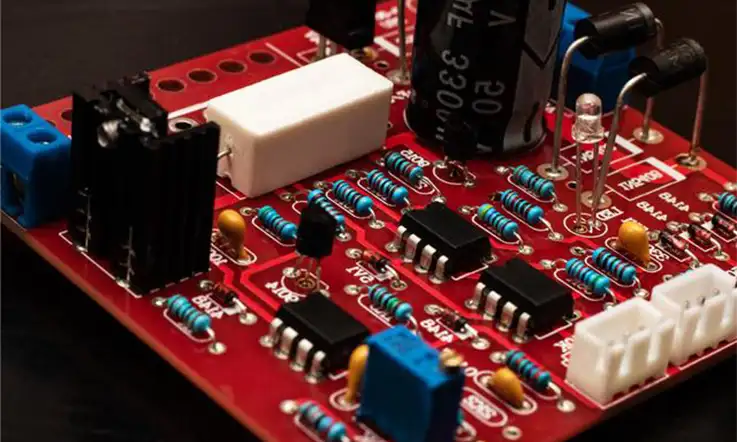

PCBs are available in a variety of colors, with green being the most common. Other colors include blue, yellow, white, transparent, black, and purple. What is the significance of the PCB colors? The color selection for each board varies and is typically based on the designers’ personal preferences, unless the consumer specifies otherwise.

PCBs with colors that are not typically utilized for aesthetic purposes are used by many designers and producers of PCBs and electronics. Typically, these types of PCBs are employed in electrical devices that are either transparent or translucent. So, the mere color of the printed circuit board (PCB) or a combination of the color of the PCB and the color of the construction material can make an electrical appear more appealing.

The following are some reasons to choose a color other than green for PCBs:

●By making use of a variety of colors, one can lessen the likelihood of making a number of different kinds of errors in a mixed assembly. The use of different color kinds has another advantage, which is that it makes it easier to identify meetings that do not involve lead.

●The use of hues other than green will result in increased brightness or a decreased sense of space.It is important to keep in mind that the transmission characteristics, absorbance, and light reflectance of assembly equipment are key factors.

●The usage of different colors of printed circuit boards (PCB) provides a visible indicator of the revision changes, which helps to keep people informed.

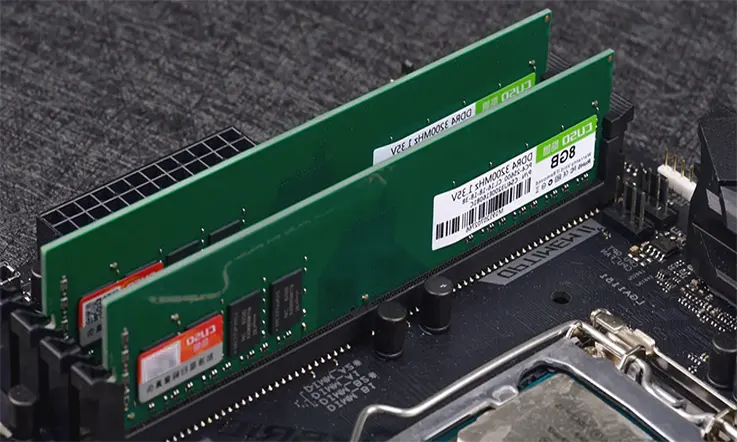

White, blue, black, yellow, and red are only few of the hues that are employed in the fabrication of printed circuit boards (PCBs). PCB color codes are a typical term for the colors of printed circuit boards (PCBs). Certain hues have been implemented across a variety of current PCB types. For instance, computer motherboards are still typically made with green epoxy today.

The performance of a printed circuit board (PCB) is unaffected in any way by the colors of the solder masks used. Yet, the board resolution will be variable due to the utilization of a variety of PCB colors. For instance, the resolution of a green PCB can be matched by utilizing red and blue colors, just as the resolution of a yellow and black color can be matched with yellow and black colors. It is important to keep in mind that solder masks that have a clear transparency typically have a high resolution.

How Do You Select the Correct PCB Colors?

So, let’s get to the meat and potatoes of the matter: how to choose the best color for your PCB board!

●Consideration Price and Quantity: When selecting the color of your solder mask, the color green will invariably be at the top of the choice. It has the lowest price point of all the colors and can be purchased in large quantities all over the place. One might also receive a decent price by going directly to the manufacturer.

●Consideration Matte and Glossy Surfaces: The choice of matte or glossy finish is totally up to the designer. The shiny finish makes them more reflecting and gives them the appearance of having a hard shell-like finish, but the matte finish has a porous surface and gives it a darker appearance. Both perform quite fine.

●Consider other PCB Product Combination:When it comes to choosing a color to utilize for the solder mask, green is one of the colors that is readily available. In most cases, this coat is the thinnest; its layer has a thickness of only 0.1 millimeters (mm). Green is the best color for printed circuit boards because it allows them to perform effectively with the most available PCB components, which makes repairs and board construction much easier.

Why Are PCB Circuit Boards Green?

The color green is the first one that likely springs to mind whenever someone mentions circuit boards. Why has green been the color of choice for circuit boards for such a significant amount of time now?

●Materials: The first answer that can be given is this one. Glass epoxy has always been the material of choice when it comes to fabricating solder masks, and these masks are green in hue. The business world eventually became used to seeing the color green. Even after solder masks became available in a variety of hues, the majority of producers continued to favor green.

Due to their prevalence, green solder coverings are now extremely cost-effective. You will observe that the fiberglass boards have a brownish-gray hue. However, you will hardly find it on modern printed circuit boards. This is because the solder barrier coating provides protection.

●Contrast: One of the reasons that green is such a popular hue for printed circuit boards is because of the contrast it provides with the white text writing on the circuit board. The majority of manufacturers perform hand inspections on their products to make certain that the printed circuit boards they sell are of a high quality.

Because green circuit boards cause less strain on the eyes, it is much simpler for you to view all of the components that make up your printed circuit board while using one of these. Also, line workers have become increasingly accustomed to working with green circuit boards. As a result, they can quickly and easily scan their green printed circuit boards, in contrast to other colors.

●Military Standards: According to a number of different sources, the United States military chose green as the hue that would work best for circuit boards in every scenario that they put it through testing for. For these reasons, green was chosen as the color for the circuit boards that would be used in military applications.

The vast majority of companies that build circuit boards do so for a variety of other clients in addition to supplying the United States military with them. Yet, the fact that the majority of their work was done for the government meant that they had an abundance of green coating. As a result, their clients spent less money on their products.

●Exposure: The exposure rate of the green solder mask is another another response to the question of why circuit boards appear green. Solder masks that are darker in color typically have a higher pigmentation level. Because of this, they have a requirement for a higher rate of exposure.

Solder masks that are white and black will require a higher rate of exposure than those with other color combinations. By selecting green as the color of your solder mask, you can also guarantee that the client will receive more stringent tolerances for their design.

●Makes mass production possible: The use of green in the coloring of circuit boards dates back quite some time. Because of this, it has developed into the color code that is most commonly used for printed circuit boards. When this is taken into consideration, it is not difficult to acquire the resources that are necessary for its manufacturing.

Also, it makes it simple to obtain for printed circuit board manufacturing companies that produce large quantities. It is helpful in facilitating mass production because this is the color that the majority of people use, so it is widely available.

●Reduced Price: Green PCB circuit boards are becoming more widely available, resulting in lower pricing. As a result, if you want to utilize bespoke colors for the solder mask, you will have to pay more. Because green solder masks are inexpensive, they have become the standard color for use on the majority of circuit boards.

How to Select the Appropriate PCB Colors Supplier?

When searching for a provider of circuit board colors, you should look for one that can reliably deliver the desired hue in the required amount. It would be beneficial if you had a supplier that is well-established in the market and is knowledgeable about the many colors of PCBs. In light of the fact that circuit boards are the primary component of any electronic material, you need to select a supplier that is able to apply the solder mask precisely.

In addition to this, the company that produces PCB ink needs to have a solid reputation in the industry. A few of the industry’s producers have been active for more than a few decades. The easiest approach to determine whether or not a manufacturer is worth doing business with is to inquire about their after-sales service.

Conclusion

It is vital to give careful consideration to the color choice for the printed circuit board (PCB). Each and every electronic project begins with the printed circuit board as its foundation. Should there be an issue with it, the operation of the entire system will be thrown off. It is imperative that you select the color of the PCB carefully because doing so is necessary in order to reduce costs by enhancing the circuit’s efficiency.

We are experts in providing our customers with printed circuit boards of very high quality and high efficiency, which is one of the reasons why we are considered as the top provider of PCB solutions in the market. As a result, we are of the opinion that the color green is the best option for the production of printed circuit boards (PCBs) because of the numerous advantages it offers in terms of its usability, including its low cost and its ease of availability.