When it comes to the tech industry, the tiniest components can pack the biggest punch—no exaggeration. Printed Circuit Boards (PCBs) are at the heart of every device, and choosing the right materials is the first step toward getting your products to sing. Enter ITEQ PCBs, where precision meets performance. This article dives deep into the nuances of ITEQ materials, manufacturing, and assembly processes, designed with industry pros like you in mind—whether you’re a seasoned electronics manufacturer, an OEM, or a savvy buyer looking to make smart decisions.

Understanding the Superior Properties of ITEQ PCB Materials

ITEQ is known for offering an extensive portfolio of high-performance PCB laminates, each crafted to handle diverse challenges in electronics manufacturing. From high-frequency communication systems to automotive electronics, ITEQ PCB materials provide solutions that ensure optimal signal integrity, thermal stability, and environmental compliance.

High Tg and CAF Resistance for Long-Term Durability

ITEQ’s wide selection of laminates, including IT-140, IT-150DA, IT-180A, and IT-400 etc, offers a wide range of performance characteristics tailored to different types of electronics applications.

For example:

ITEQ IT-150GS offers exceptional CAF resistance and thermal stability, which is ideal for high-frequency designs that require long-term durability under demanding environmental conditions.

The IT-170GLE model features high Tg that provides excellent thermal cycling stability, particularly useful in automotive electronics where PCBs must withstand extreme temperature variations.

| Material | Tg (Glass Transition Temperature) | CAF Resistance | Durability Advantage |

| IT-140 | 140°C | Good | Suitable for general applications requiring stable performance |

| IT-150DA | 150°C | Excellent | Enhanced CAF resistance, ideal for high-voltage applications |

| IT-180A | 180°C | High | Strong performance in high-temperature environments |

| IT-150GS | 150°C | Excellent | Resistant to conductive anodic filaments, perfect for high-speed circuits |

| IT-170GLE | 170°C | Very Good | Excellent for applications subject to thermal cycling |

| IT-400 | 200°C | Excellent | Best for extreme thermal environments and demanding applications |

Halogen-Free Laminates and Environmental Compliance

In today’s manufacturing landscape, environmental compliance is more important than ever. ITEQ PCBs offer several halogen-free laminate options, ensuring that manufacturers meet global RoHS standards and contribute to sustainable electronics production. The IT-150G, IT-180GN, and IT-968SE models, for instance, are particularly well-suited for compliance with both RoHS and WEEE (Waste Electrical and Electronic Equipment) regulations.

| Material | Halogen-Free | RoHS Compliant | Environmental Advantage |

| IT-150G | Yes | Yes | Free from harmful halogens and environmentally compliant |

| IT-180GN | Yes | Yes | Complies with international environmental standards |

| IT-968SE | Yes | Yes | Eco-friendly and sustainable for green manufacturing practices |

By choosing halogen-free laminates like IT-150G and IT-180GN, we not only ensure regulatory compliance but also position their products as environmentally responsible, promoting sustainability in the electronics manufacturing industry.

Thermal Stability Across High-Performance Applications

ITEQ PCB laminates are designed to meet the demanding needs of high-performance applications where thermal stability is a critical factor. Models like IT-168G1, IT-170GRA1, and IT-200LK provide excellent resistance to thermal expansion, allowing PCBs to maintain their electrical properties even in high-stress environments.

For example:

● IT-170GRA1 is particularly suited for automotive electronics, which often require consistent performance despite extreme temperature shifts.

● IT-200LK, with a Tg of 200°C, excels in aerospace and defense applications, where thermal conditions fluctuate significantly.

| Material | Tg (Glass Transition Temperature) | Thermal Resistance | Thermal Stability Advantage |

| IT-168G1 | 168°C | High | Ideal for high-frequency applications with minimal signal loss |

| IT-170GRA1 | 170°C | Excellent | Perfect for automotive systems and high-thermal environments |

| IT-200LK | 200°C | Excellent | Best for aerospace applications requiring extreme thermal resistance |

| IT-400 | 200°C | Excellent | Ideal for high-power systems with demanding thermal performance needs |

By selecting ITEQ PCB laminates, you can achieve long-term performance and reliability, regardless of the conditions your products face. Ready to boost your designs with cutting-edge PCB materials? Connect with us today to explore how ITEQ can help elevate your manufacturing processes and product quality.

Types of ITEQ PCB Laminates

ITEQ Corporation stands out in the PCB industry by offering an array of laminates tailored for diverse applications. Here’s a deep dive into their laminate categories, emphasizing their practical features, industry relevance, and unique benefits:

1. FR-4 Laminates: A Versatile Benchmark

FR-4 laminates remain a foundational material in PCB manufacturing. ITEQ’s portfolio includes both standard and high-grade FR-4 options, catering to industries ranging from consumer electronics to industrial automation. These laminates are celebrated for their:

●Electrical Insulation: Maintaining robust dielectric properties under various voltages.

●Mechanical Integrity: Providing durability across mechanical stress cycles.

●Thermal Stability: Withstanding continuous exposure to moderate heat without degradation.

Specific Grades and Applications:

●IT-140: Designed for cost-sensitive applications like household gadgets.

●IT-170GLE: Preferred for demanding circuits in industrial controls, offering a Tg of over 170°C and exceptional stability under thermal cycling.

| Specification | IT-140 | IT-170GLE |

| Tg (°C) | 140 | 175 |

| Dielectric Constant (Dk) | ~4.5 | ~4.2 |

| Thermal Conductivity (W/mK) | 0.25 | 0.38 |

2. High-Speed Digital Laminates: Precision for Data-Intensive Systems

High-frequency digital systems demand precision in maintaining signal quality and reducing transmission losses. ITEQ’s high-speed digital laminates are crafted to deliver optimal performance, featuring low dielectric constants (Dk) and minimal dissipation factors (Df). These properties ensure smooth signal flow while keeping distortion to a minimum, making them a reliable choice for applications like data communication networks and advanced computing. With these laminates, your design can handle rapid data rates effortlessly, keeping everything flowing like a well-oiled machine.

Noteworthy Products:

●IT-180A: Found in gigabit routers and data servers, offering consistent electrical performance across high data rates.

●IT-189: A preferred material for cutting-edge computing platforms requiring stable impedance at ultra-high frequencies.

Engineering Insights:

●These laminates enable impedance matching in multi-gigabit signal paths.

●Their properties are optimized to minimize crosstalk and attenuation, even in compact designs.

Use Case: In data centers, IT-189 laminates enhance server backplanes by ensuring signal clarity over long trace routes.

3. RF/Microwave Laminates: Designed for High-Frequency Mastery

RF/microwave circuits demand materials that can operate reliably at frequencies exceeding 1GHz. ITEQ addresses this with laminates optimized for applications like 5G communication infrastructure, radar systems, and satellite transceivers. Key attributes include:

●Low Loss Tangent (Df)

●Stable Dielectric Properties

Highlighted Products:

●IT-200LK: Trusted in radar systems for maintaining low loss even under fluctuating temperatures.

●IT-968SE: Widely adopted in 5G antenna modules, balancing high-frequency performance and environmental durability.

Performance Comparison:

| Property | IT-200LK | IT-968SE |

| Frequency Range (GHz) | 1-10 | 1-20 |

| Loss Tangent (Df) | 0.005 | 0.004 |

| Operating Temp (°C) | -40 to +140 | -55 to +170 |

4. High-Temperature Laminates: Resilience in Extreme Conditions

Industries like aerospace and automotive require PCB materials that maintain their mechanical and electrical properties under prolonged heat exposure. ITEQ’s high-temperature laminates, featuring low Coefficient of Thermal Expansion (CTE) and high glass transition temperatures (Tg), excel in these environments.

Key Solutions:

●IT-150DA: Ideal for automotive engine control systems, offering robust performance at sustained temperatures above 200°C.

●IT-168G1: Trusted in aerospace avionics for its ability to withstand thermal cycling without delamination.

Real-World Application: IT-150DA is used in electric vehicle (EV) battery management systems, where it endures both thermal shocks and high operational currents.

5. High-Power Laminates: Handling the Heat

For applications that demand compact power solutions, managing heat effectively becomes a top priority to maintain system reliability. ITEQ’s high-power laminates are designed with superior thermal conductivity to tackle this challenge head-on. They help dissipate heat efficiently, ensuring stable operation even in tough settings like renewable energy installations and high-performance motor drives. With these laminates, you can count on durability and consistency, even when the going gets hot.

Prominent Materials:

●IT-258GA3: Designed for energy converters in solar farms.

●IT-170GRA1: Used in high-efficiency LED lighting systems, offering improved thermal control.

Thermal Analysis:

| Metric | IT-258GA3 | IT-170GRA1 |

| Thermal Conductivity (W/mK) | 0.6 | 0.45 |

| Max Operating Temp (°C) | 260 | 200 |

6. Halogen-Free Laminates: Environmentally Responsible Innovation

As regulations tighten around environmental sustainability, halogen-free laminates have become a necessity. ITEQ’s offerings meet stringent RoHS compliance, offering a greener alternative without compromising performance.

Why Choose Halogen-Free?

●Eliminates hazardous chemicals like chlorine and bromine.

●Meets fire safety standards with non-halogenated flame retardants.

Example:

IT-968SE: Combines halogen-free properties with superior performance, making it suitable for IoT devices focused on eco-friendliness.

Advanced ITEQ PCB Laminates for Signal Integrity and Thermal Performance

ITEQ PCB materials offer a broad range of high-performance options that cater to various industries, each designed with specific attributes to enhance the performance of printed circuit boards. From telecommunications and automotive electronics to medical devices and industrial applications, ITEQ’s diverse PCB laminates are engineered to provide reliable signal integrity, thermal management, and mechanical strength.

How ITEQ PCB Ensures Signal Fidelity?

Signal fidelity is a make-or-break factor in today’s advanced electronics. Whether you’re dealing with high-speed data transfer in telecommunications or complex circuits in automotive or medical devices, signal integrity ensures that your signals remain clear and uninterrupted, no matter the environment. ITEQ PCBs are specifically engineered to ensure low-loss and consistent transmission of signals, even when dealing with high-frequency applications.

With the use of high-quality laminates like IT-180, IT-150GS, and IT-168G, ITEQ PCBs significantly reduce issues such as signal degradation, reflection, and interference. These materials are formulated to maintain stable dielectric properties and minimize signal attenuation across a wide frequency range, ensuring that data integrity remains intact. In addition, ITEQ PCBs feature highly stable copper plating and tailored surface finishes that contribute to superior performance in RF (Radio Frequency) systems, satellite communications, and 5G networks.

| PCB Model | Signal Loss (dB/inch) | Frequency Range (GHz) | Application Area |

| IT-180A | Low | High | Ideal for 5G and satellite communication |

| IT-150GS | Ultra-low | Very High | Used in RF and antenna systems |

| IT-150G | Low | Moderate | Reliable in telecom base stations |

So, whether it’s for high-speed communication systems or networked devices, choosing ITEQ PCBs means you’re getting a dependable, low-loss material that keeps signals sharp, clear, and consistent. No more worrying about signal distortion or data loss—just smooth, uninterrupted performance.

ITEQ PCB’s Thermal and Electrical Stability

When your system is cranking out high performance, it generates heat—that’s just how it goes. Without a solid thermal management solution, even the most well-engineered circuit board can break down. Fortunately, ITEQ PCBs are specifically designed to handle heat like a pro. The high-performance laminates used in ITEQ PCBs such as IT-150DA and IT-170GLE are formulated to withstand extreme temperature conditions, which is especially important in industries like automotive electronics or medical devices where high reliability is non-negotiable.

These materials come with excellent thermal conductivity, meaning they dissipate heat efficiently, protecting sensitive components from thermal stress and helping to maintain electrical stability even in harsh conditions. For example, IT-170GLE has a glass transition temperature (Tg) of 170°C, which allows it to keep working smoothly even in high-heat environments like powertrains or circuitry in medical equipment.

| Material | Thermal Conductivity | Glass Transition Temperature (Tg) | Ideal Application |

| IT-170GLE | High | 170°C | Ideal for high-power automotive systems |

| IT-150DA | Excellent | 150°C | Perfect for medical device circuits |

| IT-150GS | Moderate | 150°C | Used in wearable electronics |

Electrical reliability is a standout feature of ITEQ PCBs. With finely tuned dielectric constants and minimal energy loss due to heat, these materials ensure dependable performance over time. Designed to handle the heat—literally—ITEQ laminates excel in demanding environments like data centers, automotive systems, and robotics. Their ability to maintain stable electrical properties under high-temperature conditions keeps your electronics humming without a hitch. It’s a no-brainer for engineers looking to stay ahead of the curve.

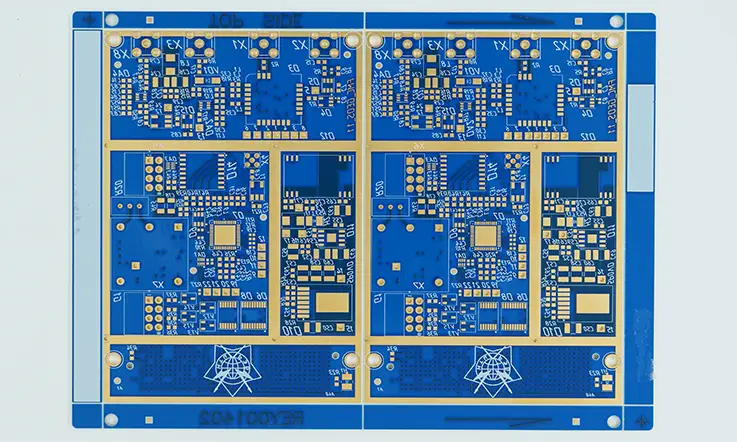

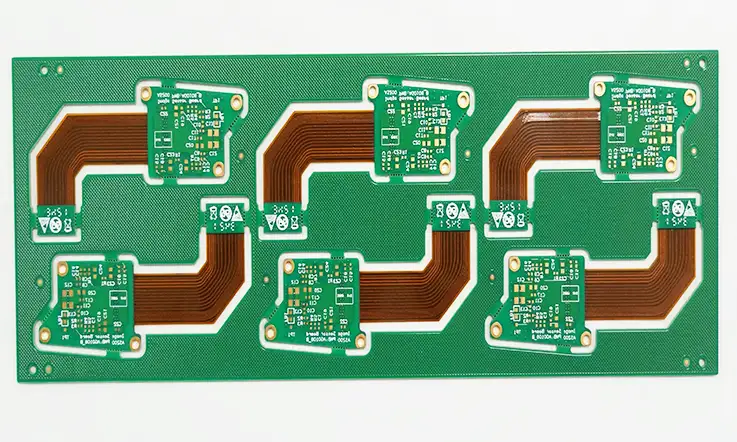

Achieving High-Density PCBs with ITEQ Materials

As modern technology demands smaller and more powerful devices, ITEQ PCBs deliver on both density and efficiency. By enabling compact designs that excel in signal fidelity and heat management, these laminates push boundaries for applications like smartphones, high-performance computing, and next-gen medical tech. Materials such as IT-150DA and IT-968 empower designers to create high-density layouts without cutting corners on reliability or functionality. Whether you’re building sleek consumer gadgets or precision-driven medical equipment, these laminates bring the right balance of durability and performance to the table—letting innovation thrive in every square inch.

Through advanced material formulation, ITEQ PCBs offer superior layer-to-layer registration and fine-pitch routing, which makes it possible to place more components into a smaller area without introducing signal distortion or thermal problems. These boards maintain reliable performance at smaller scales, which is perfect for high-frequency circuits, multilayer PCB designs, and compact devices that require maximum efficiency.

| Material | Layer Count | Minimum Trace Width | Best Use |

| IT-150DA | 12+ layers | 4 mils | Ideal for medical devices |

| IT-968 | 16+ layers | 3 mils | Great for wearables |

| IT-150GS | 8+ layers | 5 mils | Perfect for smartphones |

With ITEQ materials, creating high-density PCBs becomes a seamless process, allowing you to pack more features, more power, and more capabilities into your products without worrying about the performance bottlenecks that come from overcrowding circuits.

Comparing ITEQ PCB Laminates to Other Leading PCB Laminates

ITEQ vs. Rogers: Cost and Performance Analysis

When comparing ITEQ PCBs to other top-performing laminates like Rogers, one key consideration is the balance between cost-efficiency and performance. Rogers is well-known for its high-performance microwave materials and high-frequency laminates, but the premium pricing often puts it out of reach for certain OEMs looking for reliable performance at a more affordable cost.

ITEQ materials, such as IT-180A and IT-150GS, offer competitive performance, especially in thermal stability and signal integrity, at a lower price point than Rogers products. While Rogers excels in high-frequency applications like 5G, satellite communications, and high-speed data transmission, ITEQ PCBs can deliver similar results at a fraction of the cost, making them an attractive option for OEMs in industries such as automotive, consumer electronics, and industrial applications.

●Performance: ITEQ materials strike an excellent harmony between preserving signal quality and managing thermal demands, which is particularly useful for high-density circuit designs.

●Cost: On average, ITEQ PCBs cost 20-40% less than Rogers laminates, offering a more economical solution without compromising on quality.

●Application Suitability: Rogers is often favored for microwave and RF circuits, while ITEQ is widely adopted in multilayer PCBs for automotive and consumer electronics.

| Material | Key Strengths | Typical Applications | Average Cost |

| ITEQ | Cost-efficient, Thermal Stability, Signal Fidelity | Automotive, Consumer Electronics, Industrial | Lower than Rogers |

| Rogers | High-Frequency Performance, Microwave Applications | 5G, Satellite, RF Communications | Higher |

Thermal and Signal Integrity Comparisons with Shengyi

When it comes to thermal stability and signal integrity, Shengyi materials are often chosen for their low-loss characteristics and ability to perform well under high temperatures. However, ITEQ PCBs stand out in applications that demand consistent performance, especially when compared to Shengyi’s offerings in high-temperature electronics.

ITEQ materials like IT-150DA and IT-170GLE are designed to handle extreme heat and electrical stresses, ensuring minimal signal degradation even under high-frequency conditions. On the other hand, Shengyi’s materials tend to perform well in standard electronic applications, but they may not offer the same level of performance when faced with the thermal cycling or electrical demands of more advanced designs.

●Thermal Resistance: ITEQ PCBs can withstand long-term heat exposure up to 180°C, while Shengyi materials often top out at 150°C, making ITEQ a better option for high-reliability sectors like automotive and telecom.

●Signal Integrity: Both ITEQ and Shengyi are capable of maintaining low loss in high-frequency circuits. However, ITEQ’s laminates tend to offer better signal fidelity due to their advanced prepreg technologies.

| Material | Thermal Stability | Signal Integrity | Best Application |

| ITEQ | Up to 180°C | Excellent for High-Speed | Telecom, Automotive, Industrial |

| Shengyi | Up to 150°C | Low Loss, Standard Frequencies | Consumer Electronics, Industrial |

Why ITEQ PCB Strikes the Ideal Balance for OEMs?

For OEMs (Original Equipment Manufacturers) focused on achieving high-performance while also managing production costs, ITEQ PCBs are the perfect middle ground between price and performance. With materials that are cost-effective yet provide high reliability and signal integrity, ITEQ laminates offer a flexible solution for industries ranging from automotive to telecommunications.

ITEQ laminates like IT-180A and IT-150GS strike the right balance by providing:

●Consistent thermal performance in extreme environments

●Superior electrical performance in high-speed designs

●Affordability for high-volume production

Compared to other leading brands, ITEQ’s flexibility in handling multilayer designs with fine traces and via holes makes it a top contender in the PCB world. Furthermore, ITEQ supports a wide range of OEM applications, from automotive electronics to medical devices, while remaining competitively priced. This is a huge advantage for manufacturers who need to keep their costs low but quality high.

●Wide Application Scope: Suitable for industries with diverse needs like automotive, medical, and telecom, making it a versatile option.

●High Performance: Excellent at managing high-frequency signals and thermal loads, ideal for OEMs developing cutting-edge products.

| Brand | Strengths | Cost-Performance Balance | Ideal for OEMs |

| ITEQ | High Reliability, Affordability, Versatility | Excellent Balance | Automotive, Medical, Telecom |

| Rogers | Top Performance in RF/Microwave | High Cost | Microwave & RF Designs |

Designing with ITEQ PCB for Maximum Efficiency

Key Design Considerations for High-Frequency Applications

When designing for high-frequency applications, the stakes are high. Whether you’re designing a 5G network, RF communications, or satellite systems, the quality of the printed circuit board can make or break your entire system. When using ITEQ PCBs, the focus is on optimizing signal integrity, minimizing loss, and ensuring efficiency in high-frequency environments.

ITEQ laminates like IT-180, IT-150GS, and IT-168G stand out in these applications due to their low-loss characteristics and stable dielectric properties. Signal loss can become a serious issue at high frequencies, causing degradation in data transmission and overall system reliability. By using high-quality materials, you ensure that your design handles high-frequency signals without interference or distortion.

Key considerations when designing high-frequency PCBs include:

●Dielectric constant: Ensuring a stable dielectric constant to maintain signal clarity.

●Low dissipation factor: Reducing signal attenuation.

●Impedance control: To prevent reflections and losses.

By focusing on these parameters, ITEQ PCBs enable you to create high-performance designs for telecommunications, RF systems, and advanced networking.

| Material | Frequency Range (GHz) | Signal Loss (dB/inch) | Best Use |

| IT-180 | Up to 40 GHz | Low | 5G and Satellite Communication |

| IT-150GS | Up to 20 GHz | Ultra-low | RF systems and antenna networks |

| IT-168G | Up to 18 GHz | Low | Telecom base stations |

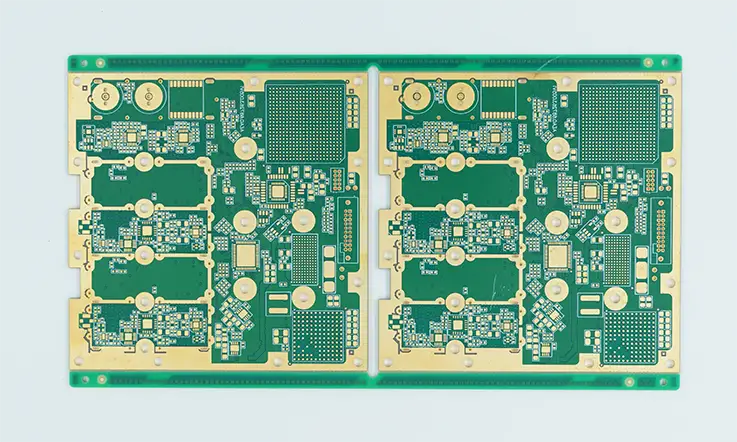

Leveraging ITEQ Laminates in Multilayer PCB Designs

Multilayer PCB designs have become a must in modern electronics, especially in compact devices such as smartphones, wearables, and medical equipment. The more layers you add, the more complex the design gets, but with ITEQ laminates, you’ve got the right foundation to support high-density integration without compromising electrical performance.

Using ITEQ materials like IT-150DA, IT-170GLE, and IT-968 allows designers to pack in more layers and components, all while maintaining signal clarity and thermal stability. These high-performance laminates help ensure that power distribution, signal routing, and thermal dissipation are handled efficiently across the multiple layers of the PCB.

When you use ITEQ materials in your multilayer PCB designs, consider these design strategies:

●Minimize layer-to-layer misalignment

●Optimal copper thickness

●Thermal vias

Material Choices for Multilayer PCBs:

| Material | Layer Count | Best Use | Thermal Stability |

| IT-150DA | 8-12 layers | Medical devices, automotive systems | Stable at up to 150°C |

| IT-968 | 12-16 layers | Smartphones, high-performance electronics | Excellent heat dissipation |

| IT-170GLE | 16+ layers | Robotics, wearables | High thermal conductivity |

By choosing the right ITEQ laminate, you can maximize your design’s density without worrying about signal degradation or thermal buildup, resulting in reliable, efficient devices that hold up under real-world conditions.

Optimizing Designs for IT-180A and IT-180ATC

When it comes to designing with IT-180A and IT-180ATC, these high-performance laminates are engineered to meet the demands of high-frequency and high-speed circuits. They excel in high-speed digital applications, 5G networks, and RF systems, where performance and signal quality are non-negotiable.

Here’s how to get the best out of these materials:

●Impedance matching: Use IT-180A for high-precision impedance control.

●Signal integrity: Ensure you are leveraging IT-180ATC for high-frequency designs that require low-loss transmission.

●Thermal management: With IT-180A and IT-180ATC, heat doesn’t stand a chance—these materials handle high power loads without breaking a sweat.

These laminates have an outstanding Tg (Glass Transition Temperature) of 180°C, meaning they can handle higher heat loads without deteriorating performance, which is a key factor in automotive electronics and industrial applications.

| Material | Glass Transition Temperature (Tg) | Best Application | Impedance Control |

| IT-180A | 180°C | 5G, RF circuits | Excellent impedance control |

| IT-180ATC | 180°C | High-speed digital circuits | Low-loss signal transmission |

By incorporating IT-180A or IT-180ATC into your design, you get a material that not only performs under high frequencies but also ensures low-loss signals and efficient power handling. Whether you’re working on telecommunications, high-frequency RF circuits, or automotive electronics, these materials are your go-to choice for achieving high-performance designs.

ITEQ PCB Laminates’s Role in High-Frequency Applications

Signal Integrity Challenges and Solutions with ITEQ

When you’re working in the high-frequency zone, keeping your signal sharp can feel like walking a tightrope. The issues that come with high frequencies—like signal reflection, crosstalk, and attenuation—can really throw a wrench in the works. And once you’re hitting those gigahertz speeds, things get even trickier. ITEQ’s PCB laminates step in here, offering top-notch materials that help dodge these pitfalls. Designed with precision in mind, these laminates provide a solid foundation for circuits that require accuracy and stability, making sure your designs hold up under the toughest conditions. Whether it’s high-speed communication systems or advanced RF applications, ITEQ has got your back, ensuring smooth sailing even when the signals start to fly.

For example, IT-180A and IT-968SE materials boast low dielectric loss (Df), ensuring minimal signal degradation across long transmission paths. These properties make ITEQ laminates the go-to choice for industries dealing with high-speed data processing or wireless communications.

A comparison of loss characteristics between ITEQ and competing materials highlights their edge:

| Material | Loss Tangent (Df @ 10GHz) | Use Case |

| ITEQ IT-180A | 0.009 | High-speed PCBs |

| ITEQ IT-968SE | 0.004 | 5G base stations |

| Standard FR-4 | 0.018 | Consumer electronics |

To tackle signal integrity hurdles, ITEQ laminates leverage advanced prepreg compositions that reduce signal reflection at critical interconnects, keeping systems humming efficiently under heavy workloads.

Optimizing RF and Microwave Designs Using ITEQ PCB

Designing RF and microwave circuits is an intricate process that demands materials with precise dielectric constants (Dk) and stable performance over wide temperature ranges. ITEQ PCB materials, such as IT-200LK and IT-170GRA1, are purpose-built for these applications. They ensure uniform signal propagation while supporting intricate layouts required in radar systems, satellite communications, and aerospace equipment.

ITEQ’s IT-200LK laminate maintains a stable dielectric constant of 3.9 ± 0.05, ensuring consistent impedance control across multilayer designs. This level of consistency is particularly beneficial for applications like phased array antennas, where even slight variations in material properties can lead to errors in signal performance. By offering precise material characteristics, IT-200LK helps maintain the accuracy required for high-performance communication systems.

In addition, many designers have also praised ITEQ for its compatibility with modern manufacturing techniques like microvia formation and low-temperature co-fired ceramics (LTCC), enabling them to achieve cutting-edge designs without compromising reliability.

The Role of ITEQ PCB Laminates Materials in 5G and IoT Devices

The rollout of 5G networks and the explosion of IoT devices have raised the stakes for PCB materials. These technologies require laminates capable of handling high data rates, dense circuit layouts, and extreme environmental conditions.

ITEQ materials rise to the challenge, combining low-loss properties with excellent thermal performance. For instance:

●5G Infrastructure: Laminates like IT-180GN excel in base station applications, where consistent performance at millimeter-wave frequencies is a must.

●IoT Devices: With their lightweight construction and adaptability, ITEQ PCBs like IT-140 offer a winning formula for compact, low-power IoT designs.

Here’s a snapshot of ITEQ’s contribution to next-gen technologies:

| Application | Recommended Material | Key Features |

| 5G Base Stations | IT-968SE | Low Df, high thermal stability |

| IoT Sensors | IT-140 | Lightweight, cost-effective |

| Phased Array Radars | IT-200LK | Precise Dk, multilayer support |

Let’s move the needle on innovation with materials built for the challenges of tomorrow. Whether you’re designing for 5G, IoT, or RF systems, ITEQ PCBs provide the foundation to make it happen.

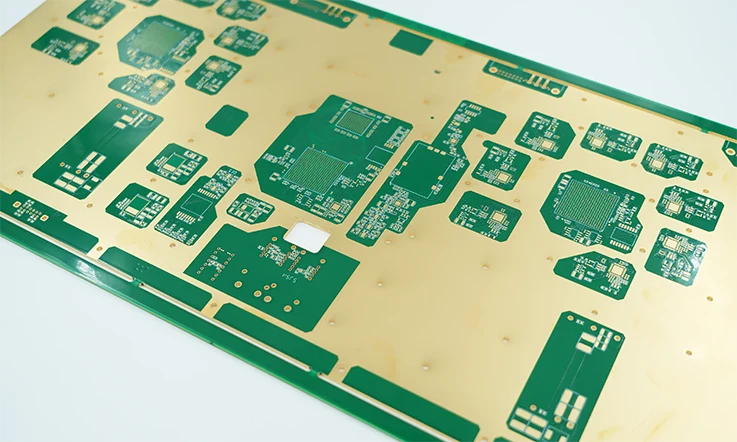

ITEQ PCB Manufacturing: Precision and Quality at Scale

Addressing Manufacturing Challenges with ITEQ Materials

Manufacturing high-quality PCBs at scale comes with its share of challenges—tolerance levels, material defects, and process reliability can all impact the final product. But with ITEQ PCBs, these challenges are met head-on, thanks to cutting-edge materials designed for precision and high yield.

ITEQ materials are formulated to handle the demanding needs of large-scale manufacturing. Their uniformity and structural integrity help ensure that each PCB meets the required specifications, even when produced in high volumes. Here are some ways ITEQ materials address the challenges of manufacturing:

●Dimensional Stability: High stability in layer registration and component placement, reducing the risk of misalignment during large-scale production runs.

●Controlled Impedance: Maintaining consistent impedance across thousands of boards, ensuring uniform performance in high-speed circuits.

●Reduced Defects: High-quality resin content and thermal cycling properties minimize defects like delamination, bubbling, and cracking that could occur during the lamination process.

This attention to detail is why ITEQ PCBs are used across industries that demand the utmost reliability, from automotive electronics to medical devices. Whether you’re dealing with complex designs or high-density layouts, ITEQ materials offer the consistency and precision needed to keep your production line humming smoothly.

| Challenge | ITEQ Solution | Benefit |

| Dimensional Accuracy | Stable laminates like IT-180A | Precise alignment throughout production |

| Impedance Control | IT-150GS | Stable signal integrity under high-frequency conditions |

| Defect Prevention | High thermal cycling resistance | Reduced delamination and bubbling during lamination |

Techniques for High-Temperature and Lead-Free Processes

Manufacturers in sectors like automotive, aviation, and medical devices face strict regulations and need materials that can endure extreme conditions. These conditions include high-temperature environments and lead-free soldering processes, both of which can challenge the material properties of traditional PCBs.

Here’s where ITEQ materials stand out. For high-temperature applications, such as those found in automotive electronics or aerospace systems, ITEQ laminates are designed with exceptional thermal stability, capable of withstanding the intense heat without compromising performance.

The high Tg (glass transition temperature) of materials like IT-180 allows PCBs to maintain their structural integrity at temperatures up to 180°C, making them ideal for high-performance electronics that are regularly exposed to extreme heat.

ITEQ PCBs are designed to meet modern sustainability standards by adhering to RoHS regulations, ensuring they are free from hazardous materials like lead, cadmium, and mercury. This eco-conscious approach not only supports green manufacturing practices but also aligns perfectly with lead-free soldering techniques. By eliminating toxic substances, these laminates provide a safer option for both manufacturers and end-users.

High-Temperature & Lead-Free Soldering Benefits:

| Material | Thermal Stability | Best Use | Soldering Compatibility |

| IT-180A | Up to 180°C | Automotive, Aerospace, Heavy-duty electronics | Lead-free, high-temperature soldering |

| IT-150GS | Up to 150°C | Industrial applications, Power electronics | Ideal for lead-free processes |

| IT-968 | Up to 160°C | Medical devices, Telecommunications | Complies with RoHS |

These materials are engineered to withstand the high temperatures of reflow soldering and the rigors of harsh environments, ensuring your designs stand the test of time.

Achieving High Yields with Advanced ITEQ Laminates

In PCB manufacturing, achieving high yields means producing a large number of high-quality boards without defects. ITEQ’s advanced laminates, such as IT-150DA and IT-180ATC, help you achieve that by maintaining uniform quality from the first board to the last.

How do they do it? These materials are designed with consistency in mind, ensuring that thermal expansion is minimized, which is a common cause of warping and yield loss during the production process. ITEQ laminates also promote efficient etching, lamination, and drilling, minimizing defects while maximizing production throughput.

For manufacturers aiming to produce high yields, ITEQ PCBs offer:

●Optimized resin systems: Reducing the chances of resin pooling and inconsistent curing during lamination.

●Superior via-hole plating: Ensuring strong electrical connections and minimizing the risk of open circuits or weak joints.

●Enhanced drillability: These laminates are engineered to support high-precision drilling processes, enabling the creation of compact, densely packed PCB layouts. With exceptional material stability and uniformity, they accommodate intricate via patterns and small-diameter holes without compromising structural integrity.

| Material | Yield Improvement Factor | Key Benefit | Best Use |

| IT-180A | Improved drilling efficiency | Reduced defects in via-hole plating | Automotive, Telecom, Medical |

| IT-150DA | Enhanced lamination quality | Higher board yield in mass production | Industrial and consumer electronics |

| IT-150GS | Lower defect rates | Consistent etching | Power electronics, Industrial applications |

Streamlining Assembly with ITEQ PCB Materials

ITEQ PCB Compatibility with Lead-Free Soldering

The shift to lead-free soldering has become an industry standard, particularly due to environmental regulations such as RoHS (Restriction of Hazardous Substances). This transition, however, presents unique challenges in terms of material performance and assembly consistency.

When selecting PCB materials, ensuring compatibility with lead-free soldering is a must, and that’s where ITEQ materials excel.

ITEQ laminates, like IT-180A and IT-150GS, are specifically designed to withstand the high temperatures and thermal stresses involved in lead-free soldering processes. These materials demonstrate superior adhesion and thermal cycling resistance, which are key factors in producing durable and reliable PCBs in lead-free assembly processes.

●Lead-Free Soldering Process Compatibility: The materials maintain excellent adhesion properties during reflow soldering, preventing issues like cold joints or delamination.

●Thermal Stability: With high Tg values, ITEQ PCBs offer exceptional resistance to heat, making them the go-to choice for high-performance electronics that undergo lead-free reflow processes.

| Material | Thermal Stability | Soldering Compatibility | Best Use |

| IT-180A | Up to 180°C | Lead-free soldering compatible | Automotive, Telecom, Medical devices |

| IT-150GS | Up to 150°C | Ideal for lead-free processes | Consumer electronics, Industrial |

ITEQ’s materials ensure that we can easily adapt to lead-free processes without sacrificing quality or performance. This provides a significant boost to the assembly process, simplifying operations and improving overall yield rates.

Assembly Techniques for High-Reliability PCBs

When manufacturing high-reliability PCBs, especially in industries like automotive, telecommunications, or medical devices, achieving consistent quality throughout the assembly process is non-negotiable. High-reliability PCBs must withstand harsh conditions, including extreme temperatures, mechanical stress, and electrical interference.

ITEQ’s materials such as IT-170GLE and IT-150DA are designed with reliability in mind, and they help streamline the assembly process by providing superior performance across various manufacturing techniques:

●Optimized Surface Finishing: ITEQ offers a variety of surface finishes compatible with both wave soldering and selective soldering techniques. These finishes ensure that solder joints remain reliable and the boards are durable even under harsh operating conditions.

●Advanced Lamination: The lamination process used in ITEQ materials ensures uniform heat distribution, which results in more reliable bonding and fewer defects during layer alignment.

●Via-Hole Plating: ITEQ PCBs are engineered to provide smooth and reliable plating in via-holes, preventing issues like poor connectivity or signal degradation that are common in traditional processes.

These manufacturing enhancements help reduce assembly time while increasing the first-pass yield and ensuring that your high-reliability designs can handle the stress of rigorous environments.

Ensuring Performance in Automotive and Telecom Sectors

The automotive and telecom sectors require PCBs that meet the demands of harsh environmental conditions while maintaining consistent performance over time. ITEQ PCBs are designed with these sectors in mind, providing thermal stability, mechanical strength, and electrical integrity.

In the automotive sector, PCBs are subjected to extreme temperatures, vibration, and electrical noise. ITEQ’s materials like IT-168G1 offer exceptional thermal cycling resistance, making them an ideal choice for engine control units (ECUs) and battery management systems (BMS).

In the telecom industry, high-frequency performance is non-negotiable. ITEQ’s high-speed materials like IT-150DA ensure that signal integrity is maintained in 5G base stations, network switches, and routers, even at high operating frequencies.

| Sector | Key Challenges | ITEQ Solution | Best Materials |

| Automotive | Temperature extremes, Vibration | Thermal stability, Mechanical reliability | IT-180A, IT-170GLE |

| Telecommunications | Signal integrity, High-speed transmission | High-frequency performance | IT-150DA, IT-968SE |

ITEQ’s materials are engineered to ensure your automotive and telecom designs meet industry standards while performing reliably in challenging environments. This makes ITEQ the go-to choice for high-performance PCBs across multiple industries.

ITEQ PCB in High-Performance Industries Applications

The demand for high-performance PCBs is rising in industries where precision and reliability are non-negotiable. ITEQ PCB materials are specifically designed to meet the rigorous standards required by high-stakes sectors like telecommunications, automotive, and medical devices. These industries require advanced solutions that can perform consistently even under the most challenging conditions. ITEQ delivers with its robust materials that combine thermal stability, environmental compliance, and long-lasting durability.

Telecommunications and RF Applications with ITEQ PCB

For telecommunications and RF applications, staying ahead in performance demands precision engineering. ITEQ PCBs are crafted to manage high-speed, complex data flows while preserving signal clarity over extended distances. Materials like IT-180A and IT-150GS are designed with low loss tangent and impressive dielectric properties, making them a reliable choice for advanced communication systems. Whether supporting cellular infrastructure, satellite networks, or the next leap in 5G, these PCBs handle demanding conditions with ease, ensuring connections remain steady and efficient.

These materials are designed to maintain consistent performance in RF environments where small changes in performance can result in system failures. ITEQ’s IT-150G, for instance, is favored for antenna systems and radar due to its stable electrical properties at elevated temperatures.

| Model | Loss Tangent | Dielectric Constant | Application |

| IT-180A | Low | Stable at high frequencies | Ideal for high-frequency RF transmission |

| IT-150GS | Ultra-low | High | Perfect for 5G base stations and antennas |

| IT-150G | Low | Consistent | Used in satellite communication systems |

For RF designs, choosing materials that can handle demanding signal requirements is non-negotiable. ITEQ PCBs deliver consistent performance with exceptional signal stability, reduced attenuation, and robust high-frequency capabilities.

Automotive Electronics: Reliability in Harsh Conditions

The automotive industry demands extreme reliability from its electronic components. As vehicles become more sophisticated, integrating technologies like ADAS (Advanced Driver Assistance Systems) and autonomous driving features, the need for durable, high-performance PCBs has never been more important. ITEQ’s IT-170GRA1 and IT-168G2 are specifically built to perform in challenging environments where temperature fluctuations, vibration, and moisture are commonplace.

For instance, IT-170GRA1 is optimized for powertrain control units (PCUs), where temperature extremes and high reliability are key to vehicle performance. These materials resist thermal expansion and thermal cycling and maintain signal integrity even when subjected to heavy-duty conditions in automotive applications.

| Material | Temperature Resistance | Vibration Resistance | Application in Automotive |

| IT-170GRA1 | Up to 170°C | High | Ideal for engine control systems |

| IT-168G2 | Up to 168°C | Excellent | Used in ADAS and safety systems |

| IT-150GS | Up to 150°C | Moderate | Automotive infotainment |

With ITEQ PCBs, you can be sure that your systems will perform consistently in harsh automotive environments, supporting everything from electrical control to infotainment systems without compromise.

Medical Devices and Industrial Applications

In the medical devices sector, precision and reliability are non-negotiable. ITEQ PCBs help meet the rigorous standards required for medical electronics, whether it’s for surgical robots, patient monitoring equipment, or wearable medical devices. Materials such as IT-150DA and IT-170GLE offer low loss, high thermal stability, and biocompatibility, making them suitable for high-precision applications that can directly affect patient outcomes.

For medical devices, reliability is just as important as performance. For example, IT-150DA’s high-temperature resistance and low-loss properties make it ideal for devices operating in intensive care units (ICUs) or surgical environments where failure is simply not an option. ITEQ PCBs are rigorously tested to ensure that they meet all necessary standards, including FDA regulations for medical applications.

| Material | Thermal Stability | Electrical Integrity | Applications in Medical Devices |

| IT-150DA | 150°C | Excellent | Used in surgical robots and monitors |

| IT-170GLE | 170°C | High | Ideal for patient monitoring devices |

| IT-150GS | 150°C | Moderate | Perfect for wearable health trackers |

In the industrial sector, ITEQ PCBs support a wide variety of applications, from robotics to automation systems, offering reliable performance even under demanding conditions. With options like IT-150DA, IT-150G, and IT-968 you can count on precision and longevity in your systems.

FAQs About ITEQ PCB Laminates

What industries commonly use ITEQ PCB laminates?

ITEQ laminates are widely used in telecommunications, automotive electronics, aerospace systems, industrial automation, and consumer electronics.

How do ITEQ laminates ensure signal integrity in high-frequency applications?

ITEQ materials feature low dielectric constants (Dk) and low loss tangents (Df), which minimize signal distortion and crosstalk in RF, microwave, and high-speed digital circuits.

Are ITEQ PCB laminates compatible with lead-free soldering?

Yes, many ITEQ laminates are specifically designed for lead-free soldering, offering high thermal stability and resistance to delamination during reflow soldering.

What are the environmental benefits of halogen-free ITEQ laminates?

Halogen-free laminates eliminate harmful halogens, such as chlorine and bromine, while complying with RoHS and other environmental standards.

Can ITEQ laminates handle extreme temperatures?

Yes, ITEQ offers high-temperature laminates with excellent thermal stability, such as IT-150DA and IT-168G1, which are suitable for automotive and aerospace applications.

Which ITEQ laminates are recommended for automotive applications?

High-temperature and high-power laminates like IT-150DA and IT-258GA3 are ideal for automotive systems, including engine control units and EV battery management.

How do I select the right ITEQ laminate for my project?

Choosing the right laminate depends on your application’s frequency, thermal, and mechanical requirements. ITEQ offers detailed datasheets and engineering support to guide material selection.

Our special materials

PCB Fabrication

ITEQ PCB Laminates & Materials Series