Choosing the right PCB material can make or break your project. Panasonic, known for top-tier products, offers a diverse range of PCB materials to cater to various applications. Their materials are designed with precision, ensuring reliable performance across different scenarios.

In this article, we’ll dive deep into Panasonic PCB materials, breaking down their features and what you need to weigh before making your pick. Whether you’re a seasoned professional or just getting started, we’ve got you covered with everything you need to make a solid decision.

Stick with us as we walk you through the essentials of Panasonic PCB materials, their unique characteristics, and the considerations you shouldn’t overlook. If you’re ready to take your project to the next level, keep reading to learn more.

Panasonic Circuit Board Materials

With manufacturing facilities strategically located across the globe, Panasonic stands tall as a prominent brand in the Circuit Board Materials sector. Their extensive product lineup covers everything from flexible materials for circuits to halogen-free options and ultra-high-speed/low-loss materials, ensuring there’s something for every need.

Circuit Board Materials Products

Megtron Series-

When it comes to top-notch performance, the MEGTRON brand is the go-to choice for engineers everywhere. This series is known for its stellar combination of reliability and quality in Circuit Board Materials.

| Product | Features | Applications |

| MEGTRON 7 | Lead-free, high-layer count, great thermal properties | Networking, high-performance setups |

| MEGTRON 6 | Robust dielectric system, smooth copper foil | Telecommunications, data centers |

| MEGTRON 4 | Excellent signal integrity, low loss | High-speed communications |

| MEGTRON 2 | Flexible, easy to work with | General applications |

| MEGTRON M | Durable, high-layer count | Advanced electronics |

Panasonic recently introduced the MEGTRON 8, a low-loss multi-layer circuit board material designed for the next generation of high-speed communications network equipment. It boasts ultra-low transmission loss, making it perfect for routers and switches.

●MEGTRON 8 is engineered for maximum efficiency, delivering 30% less transmission loss than MEGTRON 7, thereby enhancing data communication and potentially reducing power consumption. It supports 800GbE, paving the way for cutting-edge communications technology.

Hiper Series-

The Hiper Series, including Hiper V, Hiper D, Hiper M, and Hiper E, focuses on multilayer circuit boards tailored for automotive applications. These materials boast high heat resistance and reliability, making them a solid choice for demanding environments.

| Product | Features | Applications |

| Hiper V | Superior CAF resistance, through-hole reliability | Automotive electronics |

| Hiper D | High reliability in harsh conditions | Industrial applications |

| Hiper M | Great laminate processability | Consumer electronics |

| Hiper E | Lead-free assembly compatible | Safety-critical systems |

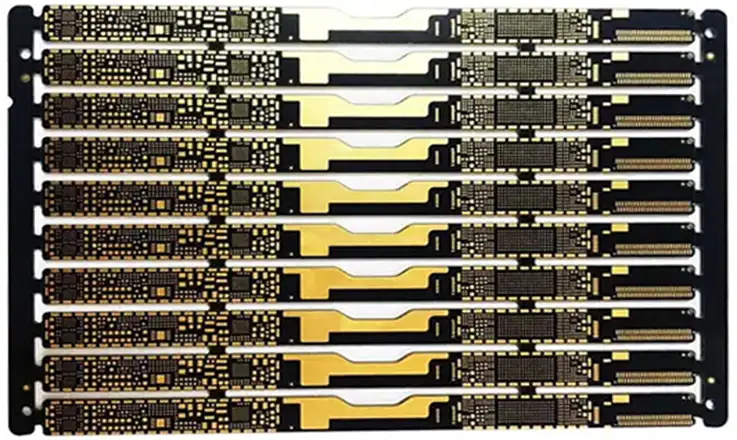

Felios Series-

For flexible circuit board needs, the Felios Series has you covered. This series includes various materials like Felios Polyimide and Liquid Crystal Polymer.

| Product | Features | Applications |

| Felios R-F775 | Double-sided flexibility, excellent thermal resistance | Mobile devices |

| Felios R-F770 | Single-sided options, high dimensional stability | Medical devices |

| Felios R-F705S | Liquid Crystal Polymer, superior flexibility | Avionics applications |

| Felios R-BM17 | Low Dk bonding sheets | Various end-use products |

These flexible circuit boards excel in thermal resistance and dimensional stability, making them ideal for use in mobile devices and industrial applications.

Halogen Free Series-

Panasonic’s Halogen Free Series features eco-friendly multi-layer circuit board materials. These materials, free from halogens and antimony, meet UL flammability tests with flying colors.

| Product | Features | Applications |

| R-5575 | High heat resistance, eco-friendly | Green technology applications |

| R-5515 | Reliable in harsh environments | Consumer electronics |

| R-A555W | Prepreg options, excellent stability | Industrial uses |

Let’s Connect!

Are you eager to learn more about Panasonic’s high-quality Electronic Materials? Don’t hesitate! Drop us an email at [email protected] today! We’re here to help you find the perfect PCB solutions for your projects.

Mastering Panasonic PCB Technology for High-Performance Circuit Boards

When it comes to high-performance circuit boards materials, Panasonic has been at the forefront of innovation and reliability. Their PCBs base materials are not just your run-of-the-mill boards; they are engineered to endure intense applications across various industries. Consider the aerospace sector, where satellites must operate flawlessly in the vacuum of space, or the telecommunications field, which demands unwavering connectivity. Panasonic’s PCBs materials are designed to meet these challenges head-on.

Durability and Long-Term Reliability

When it comes to choosing materials that can handle demanding applications, Panasonic PCB materials are at the forefront. Whether you’re working on an automotive control system that needs to endure rough environments or a medical device that requires consistent performance, these boards are designed for the job. Panasonic’s advanced materials, combined with state-of-the-art manufacturing techniques, ensure that their PCBs perform reliably, even when the going gets tough.

For example, consider the application of Panasonic PCBs in aerospace systems. In a recent project, engineers relied on Megtron 7 for a satellite’s main communication board. This specific material’s high thermal stability and low dielectric loss ensured that the board operated seamlessly during launch and while orbiting the Earth. Without reliable PCBs, the entire communication system could fail, potentially leading to a costly mission loss.

Performance Under Pressure

In industries where reliability is non-negotiable—like automotive and defense—Panasonic’s technology truly stands out. Their PCB base materials are designed to withstand extreme conditions, from high heat to constant vibrations, without losing their structural integrity. This makes them a go-to choice for demanding applications such as engine control units (ECUs) in vehicles. These ECUs need to operate smoothly, even under fluctuating temperatures and pressure changes, ensuring that your vehicle’s systems remain dependable no matter what’s happening under the hood.

Built Tough for High-Stakes Applications-

From the rugged demands of military equipment to the precision required in automotive systems, Panasonic’s PCB materials are tailored for environments where performance can’t afford to falter. The advanced formulations provide resistance to both mechanical stress and heat, making them a smart pick for electronics that operate in harsh conditions. Whether you’re dealing with temperature spikes or heavy vibration, Panasonic PCBs keep your systems working consistently.

By working with Panasonic PCB technology, you’re choosing materials that are up for the challenge, ensuring that your automotive or defense systems stay reliable through it all. Got a project that needs to stand up to tough conditions? Let’s talk—JarnisTech can help bring your ideas to life with Panasonic’s high-performance solutions.

Table: Comparison of Panasonic PCB Materials

| Material | Glass Transition Temperature (Tg) | Dielectric Loss Factor | Application |

| Megtron 6 | 180°C | 0.01 | Telecommunications |

| Megtron 7 | 210°C | 0.005 | Aerospace and Military Systems |

The table above illustrates how Panasonic’s materials stand out in terms of thermal performance and dielectric properties, making them a go-to choice for high-stakes applications.

The Heart of Your Electronics

For mission-critical projects, selecting the right PCB materials is non-negotiable. It’s about ensuring that the backbone of your electronics is strong and reliable. When you incorporate Panasonic technology, you’re not just buying a product; you’re investing in peace of mind. These boards materials undergo rigorous testing and quality control processes, ensuring that they meet the highest standards of performance.

The Benefits of Panasonic PCB Materials in High-Pressure Industries

When you’re deep in the trenches of high-pressure industries like aerospace and automotive, you quickly learn that using dependable PCB materials isn’t just a suggestion—it’s a must. Trust us, we’ve been around long enough to see what happens when things go sideways. That’s where Panasonic PCB materials come into play, consistently delivering top-notch performance while standing strong under extreme conditions.

Proven Track Record

In the world of aerospace, every single detail counts. Whether it’s a satellite that needs to function flawlessly in the vacuum of space or a jet engine control system that can’t afford a hiccup, Panasonic PCB materials are the go-to choice. These boards materials have a proven track record of durability and reliability that companies like mine can count on.

Take, for example, a recent project we handled involving a satellite communication system. We opted for Panasonic’s Megtron 6 due to its outstanding ability to manage heat and minimize signal loss. This material performed exceptionally well, maintaining strong signal quality despite the harsh environment of space. The PCB materials were incredibly user-friendly during the production process, and after a battery of intense tests, they showed no signs of giving in under pressure.

When you need to keep your systems running smoothly in extreme conditions, like outer space, Megtron 6 proves to be a rock-solid choice. Whether it’s high temperatures or demanding signal requirements, it gets the job done. If you’re tackling a project where reliability isn’t an option—reach out to us at JarnisTech, and we’ll make sure your PCB solution is ready to handle the toughest environments.

Advanced Materials for Complex Circuits

Now, let’s dive into Panasonic’s Megtron 7—a powerhouse when it comes to managing intricate circuits. This material really steps up where precision is non-negotiable. Whether you’re dealing with high-speed data or sensitive signals, Megtron 7 ensures your circuitry stays sharp without interference creeping in. The last thing you need is signal noise throwing a wrench into your system, right?

With Megtron 7, we’re talking about a material designed to minimize signal loss while ensuring reliable connections. We remember working on an automotive project where we needed a PCB that could handle high-speed data transfer without breaking a sweat. Using Megtron 7 made all the difference. The results? A reliable, high-performance circuit board that stood up to the demands of modern automotive systems.

With Megtron 7, you can count on clean, clear signal flow even in the most challenging environments. From high-frequency applications to complex systems that demand top-notch performance, this material gives you the edge. If you’re looking to fine-tune your design with no room for error, we’ve got the solution. Reach out to us at JarnisTech, and we’ll set you up with the best Panasonic PCB materials to keep your project on track and on target.

Table: Key Benefits of Panasonic PCBs

| Benefit | Description |

| Reliability | Proven performance in extreme conditions |

| Signal Integrity | Maintains clarity even at high speeds |

| Durability | Stands up to thermal and mechanical stress |

| Application Versatility | Suitable for aerospace, automotive, and telecommunications |

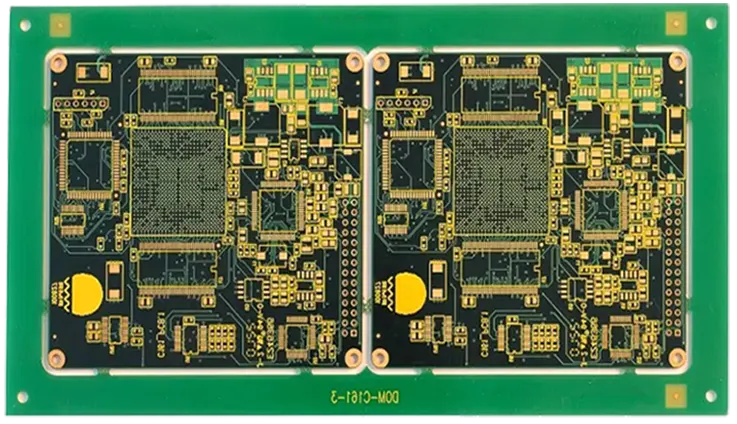

Optimizing Multilayer PCB Design with Panasonic Materials

If you’ve ever dived into the world of multilayer PCB design, you know it can be a real puzzle. It’s all about juggling various elements—managing signal integrity, making sure the layers don’t step on each other’s toes, and keeping everything within specs. But here’s the good news: Panasonic’s materials come to the rescue, turning a daunting task into a streamlined process.

Panasonic’s Material Advantages

When you’re working with multilayer PCB designs, Panasonic’s got you covered with materials built for top-tier performance. Take Megtron 7, for example. This material cuts down on interference while keeping your signals crisp, ensuring no hiccups even in high-speed data transfers. Picture yourself designing a multilayer board for intense data transmission—Megtron 7 gives you that reliability without bulking up your design.

Let’s not forget about Panasonic’s advanced low-loss materials. These solutions are engineered to minimize signal degradation between layers, allowing your designs to thrive. As someone who has navigated the labyrinth of PCB design, we can tell you that using these materials is like having a secret weapon. You get the efficiency of a well-optimized board without the usual headaches.

Table: Benefits of Panasonic Materials in Multilayer PCB Design

| Benefit | Description |

| Signal Integrity | Maintains strong signals across layers |

| Reduced Interference | Minimizes crosstalk between layers |

| Compact Design | Allows for denser designs without sacrificing performance |

| High-Frequency Handling | Effectively manages high-speed data without signal loss |

Tackling the Complexities of Multilayer Design

When diving into the nitty-gritty of multilayer PCB designs, one of the major headaches is signal loss between layers. This issue can turn your smooth-sailing project into a rocky mess faster than you can say “PCB.” Thankfully, Panasonic’s materials are engineered to keep everything crisp and clean. This means fewer design revisions, allowing us to hit the market quicker and with confidence. Talk about a time-saver!

Why Panasonic Materials Shine?

Panasonic’s materials, such as Megtron 6 and Megtron 7, are designed to handle high frequencies without adding unnecessary bulk. This is huge for any PCB layout engineer. Nobody wants a board that’s thicker than a pancake and just as heavy! These materials facilitate efficient signal transmission, ensuring that our designs remain sleek while still packing a punch in performance.

Table: Advantages of Panasonic Materials in Multilayer Design

| Advantage | Description |

| Signal Integrity | Minimizes signal loss, ensuring clean communication between layers. |

| Compactness | Allows for slim designs without compromising on functionality. |

| High-Frequency Performance | Handles high-speed data efficiently, perfect for modern applications. |

| Flexibility | Adaptable to various applications, from telecommunications to consumer electronics. |

One real-world application we encountered involved designing a multilayer PCB for a telecommunications system. The client demanded high-speed data transmission and low signal degradation. By using Panasonic’s Megtron materials, we kept our layers in check and avoided those pesky revisions that can derail a project. It was a home run, allowing us to deliver a product that was not only functional but also ahead of the curve.

Innovation Meets Design

The flexibility that Panasonic’s materials offer opens doors for innovation in design. Whether your project is a compact consumer gadget or a robust industrial device, these PCBs support creativity and technical advancement. You’ll find them in high-end applications where performance and reliability are non-negotiable.

Think of it this way: using Panasonic materials means you’re not just keeping up with the competition; you’re setting the pace. If you’re looking to elevate your PCB designs, these materials make it easier than ever to push the envelope while staying true to your project specs.

Enhancing Signal Integrity in High-Frequency PCB Designs

When it comes to signal integrity, let’s be real—it’s the backbone of high-speed electronics. Whether you’re working on a motherboard or getting into RF applications, keeping those signals strong and free from interference is non-negotiable. In environments where every nanosecond matters, you’ve got to have your boards perform seamlessly without signal drop or degradation.

Take Panasonic’s Megtron materials, for instance. They’re designed to keep the flow smooth and interference at bay, so whether you’re pushing data through a high-speed communication network or fine-tuning sensitive RF circuits, you know your signals are safe from noise and loss. The bottom line? You need materials that won’t buckle under pressure and deliver the kind of performance your design demands.

Panasonic’s High-Performance Materials

Enter Panasonic’s lineup, particularly the Megtron 6 and Megtron 7 series. These materials are specifically engineered to tackle the signal integrity challenge head-on. Think of them as the bodyguards for your signals. Designed to minimize signal loss and prevent interference, these materials ensure that your designs maintain peak performance—even in high-frequency environments like 5G networks. A single drop in signal can be a dealbreaker, and Panasonic’s got your back.

Key Benefits of Panasonic Materials

| Feature | Description |

| Low Loss | Megtron materials are designed for minimal signal degradation, keeping your signals intact. |

| High Frequency Capability | Ideal for 5G applications and other high-speed systems, allowing for faster data transmission. |

| Thermal Stability | These materials maintain performance under varying temperature conditions, ensuring reliability. |

| Compatibility | Works seamlessly with various PCB designs, from consumer electronics to industrial applications. |

Real-World Solutions for Signal Integrity Challenges

Having spent years in the trenches with high-frequency PCBs, we can confidently say that Panasonic materials have come to the rescue time and again. Their impressive ability to maintain strong signals—even in the most complex multilayer designs—makes them the go-to choice for any serious engineer operating in industries like telecommunications, automotive, or medical device manufacturing.

Panasonic’s Unique Materials

What sets Panasonic apart? It’s all in the way their materials tackle signal integrity issues. Megtron 6 and Megtron 7 materials are specifically designed to handle high-speed signals without breaking a sweat. These boards don’t just perform well; they excel under pressure, ensuring that signal loss is kept to an absolute minimum. Check out this table that breaks down their key attributes:

| Material | Attribute | Benefit |

| Megtron 6 | Low dielectric loss | Maintains signal strength, especially in multilayer designs. |

| Megtron 7 | High thermal stability | Performs reliably across a wide range of temperatures. |

| Advanced Resin | Robust mechanical properties | Withstands physical stress, ensuring longevity and durability. |

Panasonic PCB Manufacturing Process: From Concept to Completion

The journey from concept to completion in PCB manufacturing is an intricate dance, and with Panasonic, every step of that dance is choreographed to perfection. Whether you’re knee-deep in the early design phase or navigating the complexities of production, the Panasonic PCB manufacturing process focuses on precision and quality. Each phase, from prototyping to full-scale production, is handled with care, ensuring nothing is left to chance.

High Standards at Every Step

Panasonic’s process ensures that every board meets the highest standards. Think of it as a finely-tuned engine; each component must work together seamlessly. Here’s a quick overview of the key stages involved in their manufacturing process:

| Stage | Description | Importance |

| Prototyping | Initial design validation to refine specifications | Helps catch design flaws early, saving time and costs. |

| Material Selection | Choosing high-quality materials like Megtron series | Ensures durability and performance in high-frequency applications. |

| Manufacturing | Precision machining and layering techniques | Guarantees dimensional accuracy and reliability. |

| Testing | Rigorous quality checks throughout the process | Identifies issues before boards reach the customer. |

| Delivery | Timely shipping and logistics management | Keeps your project on track, meeting those tight deadlines. |

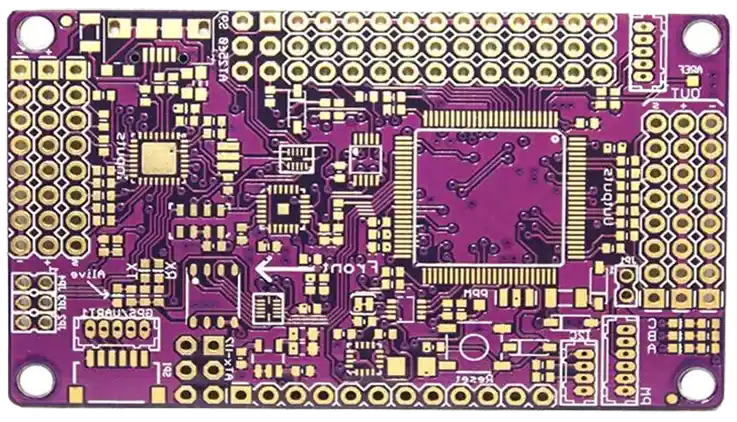

Custom PCB Manufacturing for OEMs

When you’re working with OEMs (Original Equipment Manufacturers), it’s all about delivering tailored solutions. Panasonic understands this need for flexibility, which is why their PCB base materials process is designed to handle custom requests with ease. Whether you’re dealing with intricate specifications or unique requirements, Panasonic’s manufacturing approach adapts seamlessly, ensuring that no matter how complex the order, it’s managed efficiently and with top-tier quality.

Tailored to Your Needs

Here’s where the magic happens: Panasonic’s custom manufacturing process ensures that you get exactly what you need, no matter the scale. Whether it’s a large-scale production run or a small batch of prototypes, their approach is designed to deliver precision. Take, for instance, a recent project where an automotive OEM needed a specialized PCB for a safety system. With Panasonic’s robust manufacturing capabilities, they were able to produce high-quality PCB boards materials that met stringent safety standards without delays.

This kind of attention to detail not only keeps engineers happy but also fosters smoother collaboration between teams. You know how it is—when the engineers and manufacturers are on the same page, everything falls into place like a well-oiled machine.

Comparing Rogers 4350B vs. Panasonic Megtron 6 for High-Frequency Applications

Let’s dive into the nitty-gritty of high-frequency PCB materials! In the corner of performance and reliability, we have Rogers 4350B, and facing off against it, we’ve got Panasonic Megtron 6. Both are top contenders in the high-frequency PCB arena, each bringing unique advantages to the table.

A Closer Look at Rogers 4350B

Rogers 4350B is well-known for its low dielectric loss, making it an excellent candidate for RF designs. This material excels in applications where signal integrity is a priority, especially in environments that demand stability and consistency. Its robust properties allow it to perform effectively even in extreme conditions, which is why many engineers trust it for their critical designs.

Key Features of Rogers 4350B:

| Feature | Description | Benefits |

| Low Dielectric Loss | Offers minimal signal degradation | Enhances signal integrity |

| Thermal Stability | Maintains performance in varying temperatures | Reduces risk of thermal-related failures |

| High Mechanical Strength | Withstands physical stress | Suitable for complex PCB layouts |

Enter Panasonic Megtron 6

Now, let’s talk about Panasonic Megtron 6. This material is designed for those who need top-notch performance without breaking the bank. Megtron 6 stands out with its low signal loss and excellent thermal stability, making it a prime choice for high-speed applications. Whether you’re in telecommunications, automotive, or aerospace, this material checks all the boxes for performance and cost-effectiveness.

| Feature | Description | Benefits |

| Low Signal Loss | Keeps signals strong over longer distances | Ideal for high-frequency applications |

| Cost-Effectiveness | Balances performance with affordability | A great choice for budget-conscious projects |

| Versatile Applications | Suitable for a range of industries | Adaptable for both prototypes and mass production |

The Showdown: Cost vs. Performance

When it comes to the technical showdown, it’s all about what you need. If you’re hunting for exceptional performance in RF designs, Rogers 4350B delivers with its low dielectric loss. However, if cost-effectiveness and reliable performance are on your radar, Panasonic Megtron 6 often takes the cake, especially in industries where balancing budget with quality is paramount.

Which Material is Right for Your Project?

If you’re scratching your head, wondering which material is right for your project, don’t sweat it. Both Rogers 4350B and Panasonic Megtron 6 are excellent options, but the choice really comes down to your specific needs. Need something that’s going to perform well in high-speed, high-frequency environments? Go with Megtron 6. Looking for low-loss performance at a slightly higher cost? Rogers 4350B might be your pick.

The key here is understanding your project’s unique needs and picking the requirements that align with them. If you’re focusing on high-speed applications like 5G networks or advanced telecommunication systems, Panasonic Megtron 6 offers the reliability and cost-effectiveness that’ll keep your project on track without breaking the bank. However, if your project demands extreme performance in RF applications with low dielectric loss, Rogers 4350B is a solid competitor.

Factors to Consider When Choosing Panasonic PCB Material

Selecting the right Panasonic PCB material isn’t just a shot in the dark; it’s a meticulous process that hinges on several key factors. Let’s break it down so you can make an informed choice that fits your project like a glove.

| Factor | Description | Considerations | Examples of Suitable Materials |

| Operating Environment | Assess the environment where the PCB will be used. Factors like moisture, temperature extremes, and chemical exposure can impact material choice. | – Humidity levels – Exposure to chemicals – Temperature variations | – R-1786 (not recommended for extreme settings) – MEGTRON series (high-performance environments) |

| Temperature Control | Evaluate how the PCB material performs under varying temperatures. Look for materials that maintain stability and low Dk values at high temps. | – Maximum operating temperature – Temperature fluctuation tolerance – Dk change with temperature | – MEGTRON 8 (designed for high-speed applications) – Hiper series (high heat resistance) |

| Space Constraints | Consider the physical space available for the PCB. Materials that allow for compact designs can enhance device performance and functionality. | – Size limitations of the device – Layer count restrictions – Flexibility of design | – Felios Series (ideal for flexible applications) – Low-profile materials (space-saving) |

| Cost Considerations | Analyze the budget for your project. The cost of materials can vary widely; finding a balance between quality and price is key. | – Material cost per unit – Long-term value (durability, maintenance) – Bulk purchasing discounts | – R-5575 (cost-effective for standard applications) – MEGTRON series (higher upfront cost, but quality pays off) |

| Application Specificity | Different applications require different properties. Make sure to choose materials that align with your specific project needs, whether for automotive, medical, or consumer electronics. | – Compliance with industry standards (e.g., UL) – Tailored properties (flexibility, rigidity, heat resistance) | – Hiper Series (automotive) – Halogen Free Series (eco-friendly options) |

When you’re on the hunt for the perfect Panasonic PCB material, keep these factors in mind. It’s about aligning the right material with your project needs. Don’t hesitate to reach out if you have questions—getting it right is the name of the game! If you’re ready to level up your PCB project, contact us at [email protected] today. Let’s make your ideas a reality!

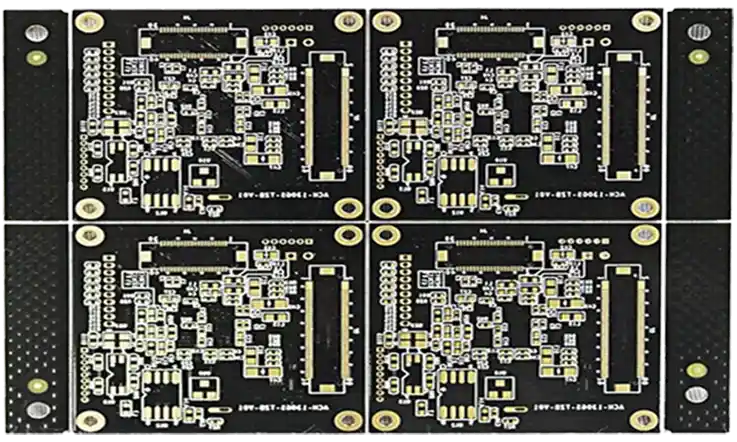

Why Should You Select JarnisTech As Your Panasonic PCB Supplier?

When it comes to sourcing Panasonic PCBs, working with a supplier that knows the ins and outs of the process is a big deal. Here at JarnisTech, we’ve spent over two decades fine-tuning our approach, and it shows in the performance and reliability of the products we deliver. We don’t just make PCBs; we craft solutions that meet the specific needs of industries ranging from network equipment to measurement instruments.

What Makes Panasonic PCBs from JarnisTech Stand Out?

Our Panasonic PCB manufacturing team is made up of a talented group of design engineers and production specialists who know that reliability and performance are non-negotiable. Here’s a closer look at what makes our boards stand out from the competition:

●Low Dielectric Constant: This feature ensures better signal integrity, especially in high-frequency applications. You can count on less signal loss, making your devices more efficient.

●Dielectric Dissipation Rate: With a Dk of 3.8 and Df of .005 at 1GHz, our materials are optimized for applications that demand low signal attenuation and high-frequency stability.

●Lead-Free Soldering: Our boards are fully compliant with modern environmental standards, including RoHS certification. This ensures you’re getting a product that not only performs but also meets regulatory requirements.

●High Heat Resistance: Our Panasonic PCBs can withstand elevated temperatures, a must-have for electronics that operate in harsh environments or undergo rigorous thermal cycles.

●Superior Through-Hole Reliability: Our FR-4 (T/C) offers 10 times the through-hole reliability compared to traditional high Tg FR-4 materials. This means fewer failures and longer product lifespans.

●Lower Transmission Losses: When compared to conventional FR-4 boards, our Panasonic PCBs experience less than 50% of the transmission losses. This translates to cleaner signals and more efficient data transfer, which is particularly useful in network equipment and telecoms.

Experience You Can Trust

At JarnisTech, we’ve been in the Panasonic PCB game for over 20 years, serving industries that demand the very best. Whether it’s building servers, routers, or advanced measuring instruments, we’ve got the experience to handle your most complex projects.

Our expertise allows us to offer tailored solutions that align with your project’s specific requirements. You’re not just getting a PCB—you’re getting a high-quality, tested product that meets stringent industry standards.

| Industry | Applications | |

| Telecommunications | Network Equipment, Routers | |

| Data Centers | Servers, Storage Systems | |

| Medical Devices | Diagnostic Equipment, Monitoring Systems | |

| Test and Measurement | Precision Measuring Instruments, RF Devices |

Why JarnisTech?

When you choose JarnisTech, you’re choosing a partner that understands what it takes to keep projects on budget and on time. With our robust quality control processes, you can be confident that every Panasonic PCB we deliver is built to perform. We handle everything from the initial design phase through to manufacturing, ensuring that every step is optimized for success.

Got a project in mind? We’re here to help make it a reality. Contact JarnisTech today and let’s get started on building the future with high-performance Panasonic PCBs. Whether you’re developing cutting-edge telecom equipment or sophisticated medical devices, we’ve got the know-how and materials to make your project a winner.

FAQ: Common Questions About Panasonic PCBs

1. What makes Panasonic PCBs different from other manufacturers?

Panasonic PCBs are known for their high-quality materials, especially the Megtron series, which offer superior thermal stability, low dielectric loss, and excellent signal integrity. This combination makes them ideal for demanding applications in aerospace, telecommunications, and renewable energy.

2. Can Panasonic PCBs be used in high-temperature environments?

Yes, both Megtron 6 and Megtron 7 are designed to withstand high temperatures, making them suitable for applications in extreme conditions, such as aerospace and industrial settings.

3. How do Panasonic PCBs improve energy efficiency?

Panasonic PCBs reduce power loss through their low-loss characteristics, which enhance the overall efficiency of power distribution systems. This can result in significant improvements in battery life for consumer electronics.

4. Are Panasonic PCBs suitable for IoT devices?

Absolutely! Panasonic’s Megtron materials allow for compact designs without compromising performance, making them ideal for the intricate needs of IoT and wearable technology.

5. What are the future trends in PCB technology?

Future trends include increased use of environmentally friendly materials, advancements in miniaturization for compact devices, and ongoing improvements in signal integrity and thermal management to meet the demands of 5G and electric vehicles.

Related Posts:

1.Panasonic R-G525T IC Substrate: Impact on Electronic Device Performance

2.Panasonic R-5515: Halogen-Free Ultra-low Transmission Loss Multi-layer Circuit Board

3.Why Panasonic HEPER R-1755E Used for Multilayer PCB Manufacturing?

4.High Heat Resistance (High-Tg) Multi-Layer PCB Material: Panasonic HEPER R-1755D