Printed circuit boards (PCBs) play a crucial role in the realm of electronics manufacturing, serving as a fundamental framework for numerous electronic devices. Hence, it is of paramount importance to employ highly efficient materials for the construction of these boards. The PCB fabrication process encompasses a diverse array of laminates tailored to various needs. In light of the progressing advancements within the PCB industry, there is an escalating requirement for multi-layer materials that offer exceptional reliability. In this article, we shall delve into the properties and characteristics of Panasonic HEPER R-1755E, a prominent PCB material.

Overview of Panasonic HEPER R-1755E PCB Materials

HEPER R-1755E PCB material is specifically designed to meet the demands of high-performance applications. It is a heat-resistant multilayer PCB material with a low coefficient of thermal expansion (CTE) and a high decomposition temperature. These properties make it highly suitable for applications where temperature fluctuations and high heat resistance are critical.

One of the notable features of Panasonic HEPER R-1755E PCB material is its compatibility with lead-free soldering. This means that it can be used in the manufacturing process without causing any issues related to lead content. This is important considering the global push for environmentally friendly and RoHS (Restriction of Hazardous Substances) compliant electronic products.

The material also offers exceptional laminate processability, making it easy to work with during PCB fabrication. It adheres to various standards in the PCB industry, including RoHS compliance, ensuring that it meets the necessary requirements for safe and environmentally conscious production. Being non-toxic, it poses no health risks during fabrication or use.

Moreover, HEPER R-1755E PCB material meets the specifications of IPC (Institute for Printed Circuits) 4101/126/97/98/99/101. IPC standards are widely recognized in the PCB industry and ensure the reliability and performance of the materials used. Therefore, Panasonic HEPER R-1755E PCB material can be considered highly reliable and suitable for demanding applications.

Properties of Panasonic HEPER R-1755E

The Panasonic HEPER R-1755E laminate boasts exceptional mechanical, thermal, and electrical properties that significantly enhance its overall performance. These inherent characteristics make it highly suitable for demanding high-frequency applications.

1.High thermal decomposition temperature:

The material has a decomposition temperature of 370 degrees Celsius, indicating its ability to withstand high temperatures without chemically decomposing.

2.Low glass transition temperature:

The material has a glass transition temperature of 133 degrees Celsius, which is relatively low. This property is important as it indicates the temperature at which the material becomes unstable.

3.Low dielectric constant:

The dielectric constant of Panasonic HEPER R-1755E is 4.6 at 1 GHz. A low dielectric constant contributes to low signal loss, making it suitable for high power applications.

4.Low dissipation factor:

The dissipation factor of the material is 0.013 at 1 GHz and 0.019 at 10 GHz. A low dissipation factor indicates the efficiency of the material as an insulator.

5.Low water absorption:

The material has a water absorption rate of 0.11%, indicating low water absorption. This property is important for maintaining the performance of the PCB and its thermal properties.

6.Low coefficient of thermal expansion:

The material has a low coefficient of thermal expansion, both in the X and Y axes. This property ensures dimensional stability and reduces the risk of warping or delamination of the PCB.

7.High dimensional stability:

Panasonic HEPER R-1755E exhibits excellent dimensional stability, maintaining its shape and size even under high temperatures or mechanical stress.

8.Good mechanical strength:

The material has good mechanical strength, enabling it to withstand mechanical stress and maintain its structural integrity.

9.Excellent electrical insulation properties:

Panasonic HEPER R-1755E offers excellent electrical insulation properties, including a high breakdown voltage and low leakage current, ensuring reliable and safe operation of electronic devices.

Panasonic HEPER R-1755E: Advantages

The Panasonic HEPER R-1755E offers a range of outstanding advantages, rendering it an optimal choice for deployment in network equipment. The benefits of Panasonic HEPER R-1755E encompass the following:

1. High heat resistance: Panasonic HEPER R-1755E has excellent heat resistance, allowing it to withstand extreme temperatures. This makes it suitable for applications that require high performance and reliability in elevated temperature environments.

2. Excellent through-hole reliability: Through-hole reliability is crucial for multi-layer PCBs. Panasonic HEPER R-1755E offers great through-hole reliability, ensuring secure connections and reducing the risk of failures or signal interruptions.

3. Industry approval: Panasonic HEPER R-1755E meets various industry standards and specifications, including RoHS compliance and IPC/4101. This indicates that the material has been tested and approved for use in PCB applications, ensuring its functionality and reliability.

4. Good CAF resistance: Conductive Anodic Filament (CAF) is a common issue in PCB fabrication, particularly in high-frequency and high-performance applications. Panasonic HEPER R-1755E exhibits great resistance to CAF, reducing the risk of electrical failures and extending the lifespan of the PCB.

5. Lead-free soldering compatibility: Panasonic HEPER R-1755E is compatible with lead-free soldering, which is now the preferred method in the PCB industry due to environmental and health concerns associated with lead soldering. The material can withstand the higher melting point of lead-free solder, ensuring reliable and safe solder joints.

Overall, the advantages of Panasonic HEPER R-1755E PCB material include its high heat resistance, excellent through-hole reliability, industry approval, CAF resistance, and compatibility with lead-free soldering. These properties make it a reliable and high-performance choice for various PCB applications.

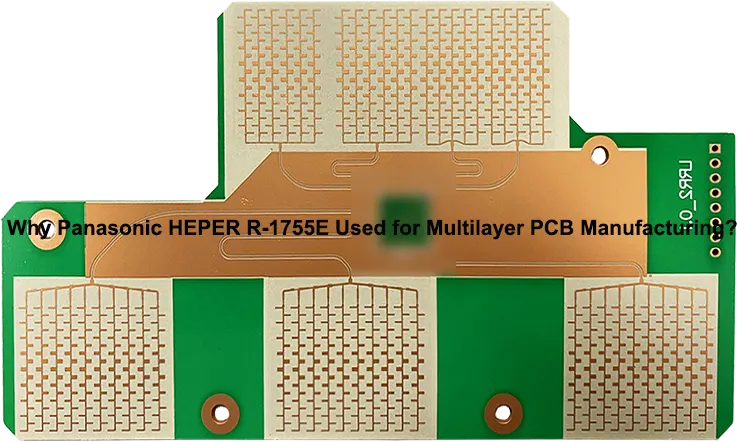

Why Panasonic HEPER R-1755E Used for Multilayer PCB Manufacturing?

Panasonic HEPER R-1755E is commonly used for multilayer PCB manufacturing due to several reasons:

1.Heat Dissipation:

Multilayer PCBs tend to generate more heat compared to single-layer PCBs due to their increased component density. HEPER R-1755E offers excellent heat resistance, allowing it to effectively dissipate heat and prevent excessive temperature rise within the PCB. This property is crucial for maintaining the reliability and performance of the PCB, especially in high-power applications.

2.Thermal Stability:

Multilayer PCBs experience thermal expansion and contraction due to temperature fluctuations. HEPER R-1755E has a low coefficient of thermal expansion (CTE), which means it expands and contracts less compared to other materials. This property helps to minimize the stress on the PCB during temperature changes, reducing the risk of warping, delamination, or solder joint failures.

3.High Signal Integrity:

Multilayer PCBs often carry high-speed digital signals or sensitive analog signals. HEPER R-1755E has excellent dielectric properties, including low signal loss and low dielectric constant, which help to maintain signal integrity and minimize signal distortion or attenuation. This is crucial for ensuring reliable communication and data transmission within the PCB.

4.Manufacturing Process Compatibility:

HEPER R-1755E offers excellent processability during multilayer PCB fabrication. It can be easily laminated, drilled, and plated, allowing for efficient and reliable manufacturing processes. The material’s compatibility with lead-free soldering processes is also advantageous, as it aligns with the industry’s shift towards environmentally friendly and RoHS-compliant manufacturing practices.

5.Reliability and Longevity:

Multilayer PCBs are often used in complex and critical applications where reliability is paramount. HEPER R-1755E’s high heat resistance, excellent thermal stability, and adherence to industry standards contribute to the overall reliability and longevity of the multilayer PCB. It can withstand demanding operating conditions, ensuring the long-term performance and functionality of the PCB.

Therefore, Panasonic HEPER R-1755E is used for multilayer PCB manufacturing due to its superior heat dissipation, thermal stability, signal integrity, manufacturing process compatibility, and overall reliability. These properties make it an ideal choice for applications that require robust and high-performance multilayer PCBs.

What’s Industry Will be Use Panasonic HEPER R-1755E PCB Materials?

Panasonic HEPER R-1755E PCB material is suitable for various industries and applications. Some of the industries that may use this material include:

1.Telecommunications:

Panasonic HEPER R-1755E is well-suited for high-frequency applications in the telecommunications industry. It offers excellent signal integrity and low signal loss, making it ideal for use in network equipment, base stations, antennas, and other telecommunications devices.

2.Aerospace and Defense:

The high heat resistance and excellent reliability of Panasonic HEPER R-1755E make it suitable for aerospace and defense applications. It can withstand extreme temperatures, vibrations, and mechanical stress, making it ideal for use in avionics, radar systems, satellites, and military communication systems.

3.Automotive:

The automotive industry requires PCB materials that can withstand high temperatures, vibrations, and harsh environments. Panasonic HEPER R-1755E’s high heat resistance, excellent through-hole reliability, and good CAF resistance make it a suitable choice for automotive electronics, such as engine control units, infotainment systems, and advanced driver-assistance systems (ADAS).

4.Industrial Electronics:

The industrial electronics sector often requires PCB materials that can withstand high temperatures, moisture, and harsh chemical environments. Panasonic HEPER R-1755E’s high thermal decomposition temperature, low water absorption, and excellent electrical insulation properties make it suitable for applications such as power supplies, motor control systems, and industrial automation equipment.

5.Medical Devices:

The medical device industry requires PCB materials that are reliable, durable, and have excellent electrical performance. Panasonic HEPER R-1755E’s high heat resistance, good dimensional stability, and low dissipation factor make it suitable for medical devices such as imaging systems, patient monitoring equipment, and surgical instruments.

6.Renewable Energy:

The renewable energy industry, including solar power and wind power systems, relies on PCBs for power conversion, monitoring, and control. HEPER R-1755E’s heat resistance and reliability make it suitable for such applications where high temperatures and robust performance are essential.

Conclusion

As technology continues to advance, the need for high-performance PCBs becomes increasingly crucial across industries. Panasonic HEPER R-1755E has proven to be a reliable and effective solution, empowering engineers and manufacturers to create cutting-edge electronic devices. With its superior heat resistance, thermal stability, signal integrity, and adherence to industry standards, HEPER R-1755E has become a catalyst for innovation and progress. As we move forward, we can expect HEPER R-1755E to play a pivotal role in shaping the future of electronics, enabling the development of more advanced, reliable, and high-performance PCBs.