In the dynamic world of electronics, IC programming and PCB assembly are two sides of the same coin. These processes work hand in hand to breathe life into electronic devices, ensuring they operate as intended. Whether you’re designing the next big gadget or simply looking to enhance an existing product, grasping the intricacies of IC programming in PCB assembly is essential.

Think of IC programming as the brain behind the operation of integrated circuits (ICs). It configures these circuits to perform specific tasks within a PCB assembly, transforming a lifeless board into a functional piece of technology. This guide will navigate you through the methods, tools, and applications of IC programming in the context of PCB assembly, arming you with the knowledge you need to optimize your manufacturing processes.

What Are Programmable IC Chips?

A programmable IC chip, often called a memory chip, is an advanced integrated circuit designed with millions of transistors and capacitors that work together to store data and assist in executing code. These chips form the memory backbone of many electronic devices, serving as temporary or permanent storage units, depending on the memory type. With RAM (Random Access Memory), programmable ICs can temporarily store data, allowing devices to retrieve and manipulate information on the fly, perfect for dynamic applications. ROM (Read-Only Memory), on the other hand, serves as long-term storage, holding data permanently or semi-permanently—think of it as the memory that “sticks.”

Types of ICs and Their Programming Requirements in PCB Assembly

1. Microcontrollers in IC Programming for PCB Assembly

Microcontrollers are the backbone of today’s electronics. These compact integrated circuits power a wide array of devices, from everyday household gadgets like microwaves and washing machines to sophisticated automotive systems. Essentially, they act as the brains of these devices, processing information and controlling various functions.

Programming microcontrollers involves uploading firmware, which is a specific set of instructions that dictates how these circuits interact with other components on the PCB. To make this process smooth, engineers often use Integrated Development Environments (IDEs) such as MPLAB X for PIC microcontrollers or Arduino IDE for Arduino boards. These platforms simplify coding and debugging, enabling developers to tailor the microcontroller’s behavior to suit the unique requirements of their PCB assembly projects.

For example, when designing a microcontroller-based temperature monitoring system, an engineer might write code that continuously reads temperature data from a sensor and displays it on an LCD. Using IDEs allows for rapid prototyping, meaning engineers can test and tweak their code in real-time, leading to faster product development.

| Microcontroller Programming Tools | Features |

| MPLAB X | User-friendly interface, extensive libraries, and debugging tools |

| Arduino IDE | Simplified coding with community support and libraries for various sensors |

| Keil uVision | Targeted for ARM microcontrollers, providing robust debugging and performance analysis |

2. ASICs and FPGAs: Custom Solutions for PCB Assembly

Application-Specific Integrated Circuits (ASICs) and Field-Programmable Gate Arrays (FPGAs) are the heavyweights when it comes to specialized tasks in PCB assembly. ASICs are custom-designed chips optimized for specific applications, offering efficiency that off-the-shelf solutions just can’t match. These chips are tailored to meet exact requirements, whether it’s for high-speed processing in telecommunications or low-power consumption in wearable devices.

Programming ASICs generally requires expertise in hardware description languages (HDLs) like VHDL (VHSIC Hardware Description Language) or Verilog. This process involves translating the desired functionality into a digital format that can be fabricated onto silicon. It’s a complex task that demands a solid grasp of both programming and electronic design principles.

FPGAs, on the other hand, offer a bit more flexibility. Unlike ASICs, FPGAs can be programmed and reprogrammed even after the manufacturing process, which is a massive plus during the development phase. This reconfigurability allows engineers to experiment with different functionalities and optimize performance without the need for new hardware. For instance, an FPGA can be initially configured to handle basic signal processing and later reprogrammed to implement more complex algorithms as product requirements evolve.

| ASIC vs. FPGA Programming | ASIC | FPGA |

| Customization | Highly specialized for tasks | General-purpose, reconfigurable |

| Development Time | Longer due to design complexity | Shorter; can be modified easily |

| Cost | Higher initial costs | Lower upfront, but can increase with complexity |

3. Memory ICs and Their Programming Needs in PCB Assembly

Memory ICs, like EEPROM (Electrically Erasable Programmable Read-Only Memory) and flash memory, are crucial players in data storage for electronic devices. These components are specifically designed to hold information necessary for the proper operation of devices, such as firmware updates and user preferences. Proper programming of these memory chips guarantees that the right data is accurately written and preserved, enabling devices to run without a hitch.

When programming memory ICs during PCB assembly, engineers must ensure they interface correctly with other components. This often involves using specific communication protocols like SPI (Serial Peripheral Interface) or I2C (Inter-Integrated Circuit). These protocols facilitate smooth communication between the memory IC and the microcontroller, ensuring efficient data transfer without hiccups.

For example, in a smart thermostat, the microcontroller might need to store temperature settings, schedules, and user preferences. The engineer would program the EEPROM to read and write this data, ensuring that it retains the information even when the device is powered off.

| Memory IC Programming Protocols | Description |

| SPI | High-speed communication; supports multiple devices on the same bus |

| I2C | Simpler protocol for lower-speed communication; allows multiple devices with fewer pins |

If you have any questions or need further information about IC programming, don’t hesitate to reach out—let’s tackle those programming challenges together!

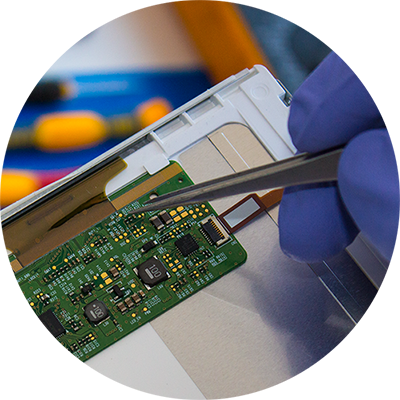

Programming Processes and Techniques for Efficient PCB Assembly

PCB assemblies (PCBAs) often need integrated circuits, and certain types—like flash memory and microcontrollers (MCUs)—require programming to function. Programming is the process of loading specific data and software into these ICs, effectively preparing them for their roles in the device.

Typically, when new IC materials arrive, they’re blank, so there’s no need to go through a clearing step. However, if the ICs aren’t new, any existing data has to be erased first to ensure no prior program interferes with the new one. Once the clearing is complete, it’s essential to confirm the IC is blank; otherwise, the new program won’t transfer correctly.

The next step, often called “burning,” involves loading (or “burning”) the program into the IC’s memory. After this, it’s necessary to verify that the program was loaded accurately. Once confirmed, additional steps like encryption or write protection may be applied to safeguard the data.

Programming, or burning, can be done in two main ways: offboard and onboard. Offboard programming happens outside of the PCBA on a dedicated programmer, while onboard programming loads data directly onto the ICs once they’re already soldered to the PCBA. Both methods offer unique benefits depending on production needs, and they each have an impact on the overall efficiency of the assembly process.

1. Onboard vs. Offboard Programming in PCB Assembly

When it comes to IC programming, engineers often weigh the pros and cons of onboard versus offboard programming. Each approach has its own set of advantages that cater to different stages of the production process.

Onboard Programming involves programming the integrated circuits directly on the PCB. This method is especially handy during the prototype phase or for smaller production runs. By programming the ICs while they’re mounted, engineers can quickly verify functionality and make immediate adjustments as needed. It minimizes the risk of component damage since everything is already in place. For instance, in the early stages of developing a new smart device, an engineer can program and test the microcontroller without having to remove it from the board, speeding up the troubleshooting process.

However, Offboard Programming is the go-to method for mass production. This approach entails programming ICs before they’re mounted onto the PCB. While it may require a bit more handling and logistics, it streamlines the assembly process significantly. Offboard programming allows for better quality control, as ICs can be tested and verified in batches before assembly. For example, in a high-volume manufacturing scenario, programming ICs in bulk can lead to more efficient use of resources and a more predictable assembly workflow.

| Feature | Onboard Programming | Offboard Programming |

| Flexibility | High (easy to tweak code) | Lower (requires reassembly) |

| Time Efficiency | Slower for large runs | Faster for mass production |

| Risk of Damage | Lower | Higher during handling |

| Quality Control | Immediate testing | Batch testing before assembly |

2. Flashing Firmware During PCB Assembly for Optimal Performance

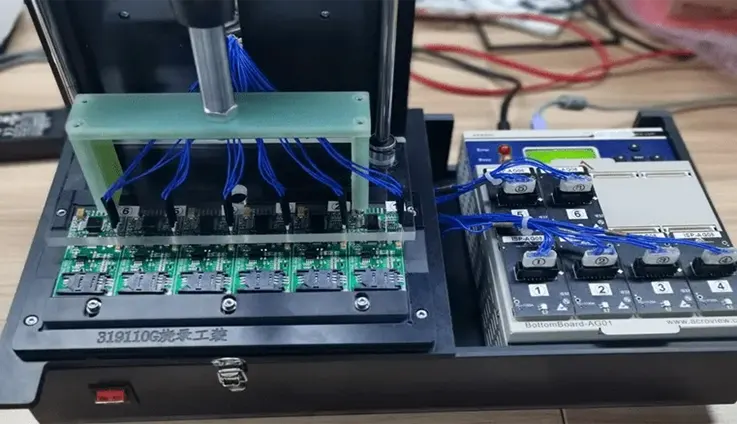

Flashing firmware onto ICs during the PCB assembly process has become a standard practice that ensures devices hit the market equipped with the latest software. This is often achieved using automated programming stations capable of handling multiple boards at once. These systems help cut down on programming time while reducing the chance for human error—nobody likes a glitchy gadget!

In a practical scenario, let’s consider the manufacturing of a new smart thermostat. As part of the assembly line, automated stations flash the firmware that allows the device to communicate with Wi-Fi networks and control HVAC systems. By doing this during assembly, manufacturers ensure that all units are ready to go right out of the box, improving customer satisfaction and product performance.

Furthermore, regular updates and patches play a key role in maintaining software health post-production. Implementing Over-The-Air (OTA) updates allows manufacturers to remotely fix bugs or add features without needing physical access to the devices. This capability enhances user satisfaction and extends the product’s lifespan. In an age where software can evolve quickly, keeping devices updated while they’re in the field is a smart move.

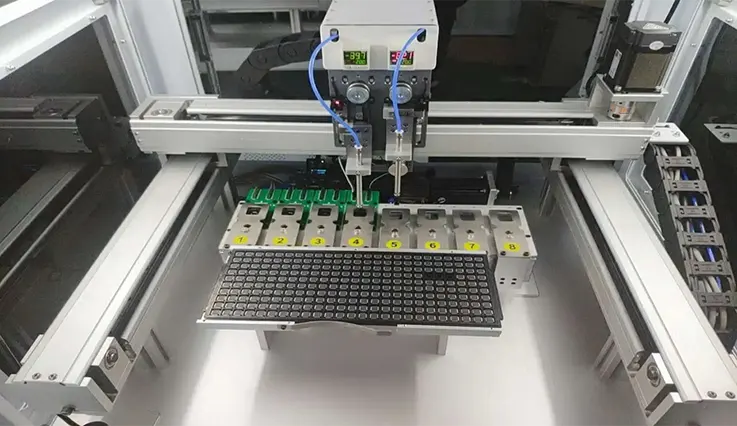

3. High-Speed and Batch Programming Techniques in IC Programming

As production volumes ramp up, speed becomes a top priority. High-speed programming techniques are designed to enable manufacturers to program multiple ICs at once, drastically cutting down on cycle times and ensuring that operations keep humming along.

Batch programming is a technique where multiple ICs are grouped together and programmed simultaneously. This method reduces downtime and maximizes throughput, allowing manufacturers to meet market demands without compromising quality. For example, if a company needs to program a thousand microcontrollers for a new product launch, using batch programming could streamline the entire process, helping to keep everything on schedule.

Moreover, advancements in programming technology have introduced various high-speed tools and methodologies that support this process. Engineers can utilize devices like parallel programmers that facilitate programming multiple chips at once, making production as smooth as butter.

| Technique | Description | Advantages |

| High-Speed Programming | Programming multiple ICs simultaneously | Increases efficiency |

| Batch Programming | Grouping ICs for simultaneous programming | Reduces downtime |

| Parallel Programmers | Tools that enable multiple chips to be programmed together | Saves time, boosts output |

What Programmable Language Is Used for IC Chips?

IC chips can be programmed in several languages and file formats, and at JarnisTech, we work with a broad spectrum of file formats to support diverse customer needs. For anyone needing guidance on file compatibility or programming options, we’re here to help get you the info you need to make the right choice.

To keep IC software working right, it’s important to use files in formats that are compatible with your specific applications and requirements. Here are the most commonly utilized formats for IC programming:

●Binary File Format: This is a straightforward format where code is stored as binary data, allowing for direct use in memory chips.

●Intel Hex File Format: Popular in microcontroller programming, this format represents binary data as hexadecimal characters. It’s used extensively for systems that require clear, readable data.

●Motorola S-Records File Format: This format organizes binary data into ASCII hexadecimal, often used in embedded systems.

●Tektronix File Format and Extended Tektronix: Designed by Tektronix, this format uses ASCII characters to represent data, including support for extended addressing which accommodates larger data sets.

●POF File Format: Primarily used for Altera (Intel) programmable devices, POF files (Program Object Files) enable storage and distribution of programming data in a portable format.

Each of these formats offers unique features to accommodate the wide range of programming and memory requirements found in modern electronics. Binary files, for example, are often used for simplicity and direct use, while Intel Hex and Motorola S-Records bring in structured data for microcontrollers.

Equipment and Tools for IC Programming in PCB Assembly

1. Automated Device Programmers for Efficient PCB Assembly

Investing in automated device programmers can transform your IC programming process from a tedious task into a well-oiled machine. These devices are designed to program large batches of ICs with speed and precision, allowing your team to focus on more strategic activities.

Choosing the right automated programmer hinges on several factors, including the types of ICs you work with and your production volume. For instance, if your operation primarily involves microcontrollers, a programmer that supports a variety of architectures and interfaces will be beneficial. Some popular choices in the market include systems from companies like Universal Instruments and Data I/O. These brands offer versatile solutions that cater to different programming needs, such as multi-site programming capabilities that can handle several ICs simultaneously, thereby ramping up productivity.

Consider a scenario where a manufacturer needs to program thousands of microcontrollers for a new line of smart appliances. With an automated device programmer, they can run multiple boards through the programming station at once, drastically cutting down on programming time and reducing labor costs. The investment in such equipment pays off in increased throughput and reduced error rates.

| Feature | Automated Device Programmers | Manual Programming |

| Speed | High (multiple ICs simultaneously) | Low (one at a time) |

| Labor Requirement | Low (minimal human involvement) | High (more hands-on) |

| Accuracy | High (consistent results) | Variable (dependent on operator) |

| Scalability | High (easy to scale production) | Low (limited by manual processes) |

2. Selecting the Right Flashers for IC Programming in PCB Assembly

Flashers are indispensable when it comes to programming memory ICs and microcontrollers. Selecting the appropriate flasher can significantly enhance your IC programming efficiency and ensure that your firmware is uploaded correctly.

When choosing a flasher, keep in mind several crucial factors such as programming speed, compatibility with various ICs, and how well it integrates with your existing production line. Brands like WARP and Xeltek provide robust solutions that meet a wide range of programming needs. For instance, Xeltek’s SuperPro series is renowned for its fast programming speeds and compatibility with a vast array of ICs, making it a popular choice in high-demand environments.

In a production setting, imagine needing to program a batch of EEPROMs for a line of electronic devices. By utilizing a flasher that supports parallel programming, manufacturers can reduce programming time from hours to minutes, enabling quicker turnaround times and improving overall efficiency.

| Feature | Flasher A (e.g., WARP) | Flasher B (e.g., Xeltek) |

| Programming Speed | Up to 50 ICs/minute | Up to 70 ICs/minute |

| Compatibility | Limited to specific IC families | Wide range (many families supported) |

| Integration Ease | Requires additional software | Plug-and-play integration |

3. Maintenance of Programming Equipment for Reliable PCB Assembly

Just like any other machinery in your production line, programming equipment requires regular maintenance to ensure dependable performance. This maintenance includes routine checks, software updates, and periodic calibration to maintain accuracy.

Implementing a preventive maintenance schedule can help avoid unexpected downtime, which can throw a wrench in production timelines. For example, a well-maintained programming station will be less likely to experience failures during a high-volume production run, which can lead to costly delays.

Consider setting up a maintenance checklist that includes tasks like inspecting the programming heads, verifying software versions, and cleaning connection points. This proactive approach can extend the lifespan of your tools and maintain the quality of your programming output.

| Maintenance Task | Frequency | Purpose |

| Software Updates | Monthly | Ensure compatibility and features |

| Calibration | Quarterly | Maintain programming accuracy |

| Connection Cleaning | Bi-weekly | Prevent signal interference |

Software Solutions for IC Programming and Code Management in PCB Assembly

1. Software Tools for Effective IC Programming in PCB Assembly

Choosing the right software tools can give your IC programming setup a serious boost. Integrated Development Environments (IDEs), compilers, and purpose-built programming software make up the toolkit for writing, testing, and uploading code directly to your ICs.

Popular software solutions like MPLAB X IDE, Keil, and IAR Embedded Workbench come packed with features that streamline coding, debugging, and firmware updates. These tools not only make coding easier but also allow engineers to focus more on innovation rather than getting stuck in troubleshooting loops.

For example, the MPLAB X IDE provides a user-friendly interface with advanced debugging capabilities, which means that engineers can visualize how their code interacts with the hardware in real time. This makes it much easier to identify issues early on, ultimately leading to smoother production runs.

| Software Solution | Key Features | Best For |

| MPLAB X IDE | Real-time debugging, multi-language support | Microchip devices |

| Keil | Powerful compiler optimizations, RTOS support | ARM Cortex-M microcontrollers |

| IAR Embedded Workbench | Extensive libraries, efficient debugging | Broad range of microcontroller families |

The right software isn’t just about functionality; it can save you headaches down the road. Imagine running a production line with outdated or inefficient programming tools. The extra time spent debugging and troubleshooting can lead to delays and increased costs. So, choose wisely and invest in software that fits your needs.

2. Version Control and Firmware Updates in PCB Assembly

Managing firmware versions is a significant part of IC programming in PCB assembly. Employing version control systems like Git ensures that every change made to the firmware is logged. This feature is especially handy when you need to roll back to a previous version due to an unforeseen issue—think of it as your safety net.

Regular firmware updates can improve functionality and patch security vulnerabilities. For instance, consider a situation where a device is compromised due to outdated firmware. Regularly updating the firmware not only keeps your products functioning well but also protects your reputation.

| Aspect | Benefits |

| Version Control Systems | Track changes, rollback capability |

| Regular Firmware Updates | Enhanced performance, improved security |

Maintaining a solid update strategy means that devices remain competitive in the market and can adapt to new challenges. So, keep your firmware fresh and ready to tackle whatever comes next!

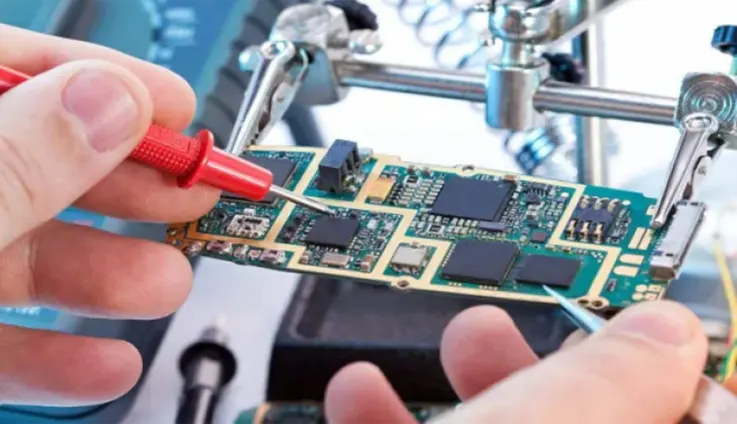

3. Debugging Code Errors in IC Programming for Quality PCB Assembly

Debugging is a crucial part of the programming process that shouldn’t be overlooked. A solid grasp of debugging techniques can save you time and frustration in the long run. It’s like tuning up your car before a big road trip—better to fix the little issues now than deal with a breakdown later.

Utilizing in-circuit emulators or debuggers allows you to catch issues early in the programming process. These tools help ensure that the final product not only meets quality standards but also performs reliably in real-world applications. For example, debugging before mass production can prevent costly reworks and lead to more satisfied customers.

| Debugging Method | Advantages |

| In-Circuit Emulators | Real-time testing, direct interaction with hardware |

| Debuggers | Comprehensive analysis of code execution |

Engineers should always conduct thorough testing before moving into mass production. A single overlooked bug can spiral into larger issues, affecting not just your production line but also customer trust. So, embrace those debugging tools, and don’t hesitate to refine your code until it’s just right!

Design for Assembly (DFA) and Its Impact on IC Programming in PCB Assembly

1. Optimizing PCB Layouts for IC Programming Efficiency

The layout of your PCB significantly influences the efficiency of IC programming. By designing PCBs with easy access to programming points, you can save time and reduce the risk of errors during the assembly process. This approach not only streamlines programming but also enhances the overall manufacturing workflow.

Using advanced EDA design software, such as Altium Designer or Eagle, allows engineers to simulate PCB layouts before physical assembly begins. These simulations can help identify potential issues early on, such as signal interference or inadequate spacing, leading to smoother operations and less hassle down the line. For instance, a well-planned layout can eliminate the need for rerouting traces, which often slows down production and complicates troubleshooting.

| Design Consideration | Benefits |

| Easy Access to Programming Points | Reduces programming time and errors |

| Design Simulations | Identifies issues pre-assembly |

| Efficient Routing | Minimizes signal loss and interference |

Implementing these strategies helps avoid last-minute changes during assembly, making the entire process more predictable. Remember, a little foresight can go a long way!

2. Component Placement Strategies for Successful PCB Assembly

Strategic component placement on your PCB can significantly enhance the IC programming process. Grouping similar components together, such as resistors and capacitors, not only simplifies the layout but also improves the flow of the assembly line.

Ensuring that programming headers are easily accessible is another key factor. When these headers are placed in convenient locations, programmers can quickly connect their tools without fumbling around. For example, aligning programming connectors along the edge of the PCB allows technicians to plug in their equipment swiftly, saving precious time during production runs.

Moreover, maintaining adequate spacing between components can minimize interference. This spacing is especially important for sensitive ICs, which may be affected by electromagnetic interference (EMI). Proper placement can improve programming reliability and efficiency during testing.

| Placement Strategy | Advantages |

| Grouping Similar Components | Simplifies assembly and reduces errors |

| Accessible Programming Headers | Speeds up the programming process |

| Adequate Component Spacing | Reduces EMI and enhances programming reliability |

The importance of a well-thought-out layout can’t be overstated—it’s the backbone of an efficient PCB assembly process. Take the time to plan it out right, and your assembly line will thank you!

3. Compatibility Considerations in IC Programming for PCB Assembly

As technology advances, ensuring compatibility among various components on the PCB is crucial. ICs must work seamlessly with other elements, such as sensors and power supplies, to perform optimally. Failure to consider compatibility can lead to significant issues, such as functionality errors or increased production costs.

Regularly reviewing compatibility standards and staying updated on industry trends can help manufacturers maintain high-quality production processes. For example, if a new IC model is released, engineers should assess its compatibility with existing components to prevent obsolescence. Keeping a keen eye on these developments can save manufacturers from headaches down the road.

| Compatibility Aspect | Best Practices |

| Regular Standards Review | Ensure compliance with the latest tech advances |

| Cross-Component Testing | Identify compatibility issues early on |

| Industry Trend Monitoring | Stay ahead of obsolescence risks |

A proactive approach to compatibility can lead to smoother production processes and higher customer satisfaction. So, keep your ears to the ground, and make sure your designs are future-proof!

Cost-Effective Strategies for Mass Production in PCB Assembly

1. Balancing Cost and Quality in IC Programming for PCB Assembly

Finding the sweet spot between cost and quality can feel like walking a tightrope for manufacturers. When it comes to IC programming for PCB assembly, it’s tempting to cut corners to save a buck. However, making sacrifices in quality can lead to costly headaches down the line.

Investing in high-quality components and reliable programming equipment can pay off in the long run. For instance, using premium microcontrollers or memory ICs might seem pricier upfront, but they typically result in fewer defects during production. Plus, satisfied customers are more likely to return for future orders.

Example: A case study with a mid-sized electronics manufacturer showed that switching to higher-quality components reduced their defect rate by 20%. This not only decreased rework costs but also improved customer satisfaction ratings.

| Strategy | Benefits |

| Invest in Quality Components | Fewer production issues, higher customer satisfaction |

| Use Reliable Programming Equipment | Saves time and reduces rework |

| Focus on Long-Term Gains | Better ROI despite higher initial costs |

The bottom line? Quality matters. It’s all about building a reputation that leads to repeat business. Don’t shortchange your product for a quick buck!

2. Cost-Effective Component Selection for PCB Assembly

The components you select for your PCB assembly can significantly impact your bottom line. To get the best bang for your buck, thorough research on suppliers is a must. Compare options not just on price but also on performance and reliability.

Consider looking into open-source hardware alternatives. These solutions often come with extensive community support, making them a cost-effective choice without compromising on quality. For instance, using open-source development boards can lower initial costs while still providing flexibility for future projects.

| Selection Strategy | Advantages |

| Research Multiple Suppliers | Identify the best value for quality |

| Explore Open-Source Options | Cost savings with community support |

| Evaluate Performance and Reliability | Ensure long-term functionality and satisfaction |

Tip: Don’t be afraid to negotiate with suppliers! A little haggling can go a long way toward securing a better deal, and many suppliers are willing to work with you to maintain a long-term relationship.

3. Scaling Batch Programming for Efficient PCB Assembly

As production ramps up, you may need to tweak your programming techniques. Batch programming is a smart way to enhance efficiency by programming multiple ICs simultaneously, which can dramatically cut down on both time and labor costs.

Implementing automated programming solutions can also support scaling efforts without sacrificing quality. For example, using automated device programmers can ensure consistent results across large production runs while minimizing manual labor.

| Batch Programming Technique | Benefits |

| Programming Multiple ICs Together | Saves time and labor costs |

| Automated Programming Solutions | Consistency and reliability across production runs |

Example: One electronics manufacturer reported that by switching to batch programming, they were able to double their production output while maintaining quality standards. This approach not only improved efficiency but also allowed them to meet rising demand without the need for additional staffing.

Automation and High-Speed IC Programming for PCB Assembly

1. Implementing Robotics for High-Speed PCB Assembly

Robotics have seriously reshaped PCB assembly, adding speed and precision to the process. Automated systems are built to handle repetitive, error-prone tasks with ease, boosting production speed while keeping mistakes to a minimum. Picture automated pick-and-place machines or robotic arms that handle the heavy lifting of component assembly—these tools take on tasks that would wear out any human, all while maintaining rock-solid accuracy.

Using robotics for high-speed assembly isn’t just about cranking up production; it’s also about creating a smoother, more reliable operation. Take automated optical inspection (AOI) systems, for instance: these can catch defects or misplacements on the fly, reducing the risk of costly reworks down the line. By setting up an automated process, manufacturers gain an edge in both speed and reliability.

| Robotic System | Description | Benefits |

| Pick-and-Place Machine | Places components onto PCBs with precision | Increases speed and reduces manual handling errors |

| Robotic Arms | Automates assembly of larger or sensitive components | Ensures accuracy and consistency |

| AOI Systems | Inspects PCBs for defects during assembly | Identifies issues early, saving on rework costs |

Pro Tip: Robotics isn’t an “all or nothing” choice—you can start with a few high-impact machines and scale up as you go. The flexibility here lets you adapt your investment as production needs change.

2. Benefits of Automated Systems in IC Programming for PCB Assembly

Automated systems bring a real boost to IC programming by transforming both speed and consistency in PCB assembly lines. By taking manual labor out of the equation, automation lowers the risk of human error, which can save you some serious cash by preventing defects and delays. Automated programming stations are built to handle large IC volumes at high speeds, helping manufacturers stay on top of deadlines while meeting customer demands.

Not only does automation cut down on errors, but it also brings unmatched consistency. When it comes to high-stakes industries like aerospace or medical devices, reliability is everything. Automated equipment is pre-set to follow strict parameters, ensuring each IC receives the exact same treatment. This uniformity isn’t just a “nice-to-have”—it’s a must if you’re looking to deliver top-quality products that meet the industry’s toughest standards.

Example: Imagine a company producing hundreds of PCBs for a medical device. By using automated programming stations, they ensure that each device is programmed precisely without risking the small variations that human handling can introduce. This isn’t just about meeting standards—it’s about protecting lives.

| Benefits of Automation | Description |

| Lower Error Rates | Reduces human error, saving on rework costs |

| High Speed | Meets high-demand schedules without sacrificing quality |

| Consistent Programming | Ensures identical programming for every IC, crucial for reliability in high-stakes sectors |

Quick Tip: Choose equipment that supports different IC types and is built to adapt to changing production needs. A bit of flexibility here can keep you nimble as market demands shift.

3. Integrating Automated Programming Stations into PCB Assembly Lines

Integrating automated programming stations into a PCB assembly line is like giving the whole process a caffeine shot. These stations can be placed strategically to maximize workflow, from placing components right through to programming and final testing. The key here? A layout that keeps the line humming, allowing components to move seamlessly from one station to the next without any bottlenecks.

When you’re in the market for automated programming stations, focus on compatibility, speed, and how well the equipment plays with your current setup. Industry leaders offer options that can handle a range of IC types, so you won’t be locked into just one configuration. It’s all about staying flexible and ready to roll with new production demands.

| Consideration | Description |

| Compatibility with IC Types | Ensures adaptability for different products |

| Speed | Supports high throughput to meet production goals |

| Ease of Integration | Allows smooth workflow without causing disruptions |

Example: A manufacturer dealing with fluctuating orders integrated flexible programming stations that supported both high-speed and specialized programming. This approach kept them agile enough to switch between different types of ICs, allowing them to handle custom orders as well as bulk runs with ease.

Quality Assurance in IC Programming for PCB Assembly

Ensuring quality throughout IC programming in PCB assembly keeps products reliable and helps prevent costly errors. Effective quality assurance (QA) protocols can reduce rework rates, minimize downtime, and boost customer satisfaction. From initial testing to debugging and compliance, these practices make sure every programmed component works as expected and meets industry regulations.

1. Testing Protocols to Ensure Quality in IC Programming

Testing is the backbone of quality control in IC programming, making sure each programmed IC performs exactly as it should. A combination of functional and in-circuit testing (ICT) can pinpoint issues at both the component and board level, allowing technicians to spot defects or irregularities early in the process. Some common testing methods include:

●Functional Testing (FT): This test evaluates the IC’s behavior against expected outputs, checking that every function works properly. Functional tests are especially helpful for identifying software issues or misconfigurations.

●In-Circuit Testing (ICT): ICT examines the IC’s physical connections, confirming the integrity of solder joints, electrical traces, and component placement. By checking these connections, ICT identifies issues like short circuits or open circuits that might otherwise go unnoticed.

●Burn-In Testing: By subjecting ICs to high temperatures or stress conditions, burn-in testing gauges reliability under extreme conditions, especially important for applications in automotive or aerospace where durability is key.

Example Table: Testing Types and Purposes

| Testing Type | Purpose | When to Use |

| Functional Testing | Verifies IC’s functionality and behavior | After programming to ensure code accuracy |

| In-Circuit Testing | Checks physical connections and components | During assembly to catch early issues |

| Burn-In Testing | Tests reliability under stress | For high-stakes applications, post-assembly |

Setting up a thorough testing protocol and sticking to it consistently allows manufacturers to catch errors right away, saving time and resources by avoiding rework and maintaining production quality.

2. Debugging Techniques for Reliable PCB Assembly

Debugging is where engineers troubleshoot and correct issues in programmed ICs to ensure they function seamlessly on the PCB. Effective debugging techniques, such as signal tracing and hardware breakpoints, help pinpoint and fix errors without holding up the assembly line.

●Signal Tracing: By tracing signals throughout the board, engineers can follow the data paths and locate any signal discrepancies. This is especially useful for identifying where an IC might not be communicating properly with other components.

●Hardware Breakpoints: Using hardware breakpoints allows engineers to pause program execution at certain points, checking the IC’s internal state. This technique is ideal for troubleshooting complex programming logic or catching errors in specific code segments.

●Boundary Scan Testing: This method allows for testing and debugging on a pin-by-pin basis, even without physical test points. Boundary scan testing works well for PCBs with densely packed components where physical access is limited.

●Automated Debugging Software: Many manufacturers use automated debugging software that integrates with the assembly line. These programs monitor for common issues, flagging anomalies so engineers can quickly step in.

3. Compliance Standards for IC Programming in PCB Assembly

Adhering to compliance standards is a must in PCB assembly, as it guarantees that the programmed ICs are safe, reliable, and meet industry and regulatory requirements. Compliance is particularly relevant in sectors like healthcare, automotive, and aerospace, where even minor deviations could have major consequences.

●IPC Standards: The IPC standards cover every stage of PCB assembly, providing guidelines for everything from soldering to environmental testing. IPC standards like IPC-A-610 and IPC-7711/7721 are widely followed for quality assurance and rework practices, ensuring the final product’s integrity.

●RoHS and REACH: Compliance with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations is crucial for products sold in the EU and other regions. These standards control the use of harmful chemicals in electronics, aligning with environmental standards and consumer safety.

●ISO/TS 16949 and ISO 9001: ISO standards, such as ISO 9001 for quality management and ISO/TS 16949 specifically for automotive manufacturing, establish best practices for consistent production quality. These standards emphasize traceability, documentation, and quality control procedures that apply directly to IC programming in PCB assembly.

Example Table: Compliance Standards and Applications

| Standard | Application | Industry Relevance |

| IPC-A-610 | Assembly and inspection guidelines | Electronics, general manufacturing |

| RoHS | Restricts hazardous substances | Consumer electronics, EU market |

| ISO 9001 | Quality management systems | All industries |

| ISO/TS 16949 | Quality management for automotive parts | Automotive manufacturing |

Industry Applications of IC Programming in PCB Assembly

IC programming is driving the push toward high-performance devices across many sectors, each with its own requirements for accuracy, durability, and regulatory adherence. From powering the newest consumer tech to supporting the reliable function of life-saving medical equipment, IC programming supports today’s electronics manufacturing by embedding the necessary instructions and safeguards into each chip.

1. Consumer Electronics: Raising the Bar in PCB Assembly

The consumer electronics industry is all about delivering sleek, powerful devices packed with innovative features. With gadgets ranging from smartphones to smart home appliances, manufacturers need ICs that are programmed to handle complex tasks without breaking a sweat. That’s where precision in IC programming comes into play, ensuring every component works smoothly to support feature-heavy applications and rapid user interactions.

For example, smartphone ICs require programming that allows for seamless communication between the processor, memory, and sensors—all while maintaining energy efficiency. Many leading consumer electronics manufacturers rely on extensive testing to check each IC’s resilience, making sure devices can handle daily use without glitches or performance drops. In fact, some brands implement a series of “stress tests,” running ICs through cycles that simulate common consumer scenarios, so their devices stay reliable even under heavy loads.

Example Table: Consumer Electronics Applications and Testing Protocols

| Device Type | Application of IC Programming | Testing Protocols |

| Smartphones | Process management, sensor integration | Functional tests, durability tests |

| Smart Home Devices | Connectivity, real-time data processing | Connectivity tests, burn-in tests |

| Wearable Tech | Health monitoring, real-time alerts | Battery endurance, stress tests |

Takeaway: For those looking to make it big in consumer electronics, there’s no cutting corners when it comes to IC programming and quality checks. Buyers expect tech that’s ready to roll, and only top-notch programming gets it there.

2. Automotive Electronics: Boosting Safety and Performance in PCB Assembly

In the world of automotive electronics, IC programming is all about precision and safety. With the surge in electric vehicles (EVs) and advanced driver-assistance systems (ADAS), automakers depend on ICs that can reliably connect with sensors, control modules, and various other components within the vehicle.

Consider the ADAS in a modern car: these systems use radar, lidar, and cameras, all coordinated by ICs programmed to interpret the inputs quickly and make real-time decisions for features like lane-keeping and adaptive cruise control. To maintain accuracy, manufacturers often conduct thorough pre-assembly simulations and road-condition tests to check each IC’s responsiveness under different driving conditions. Quality here isn’t just about performance; it’s about building trust that drivers can count on.

Example Table: Automotive Applications and IC Programming Needs

| System Type | IC Programming Focus | Testing Phases |

| Electric Vehicle (EV) | Battery management, motor control | Thermal testing, in-circuit testing |

| ADAS | Sensor processing, control feedback | Environmental simulation, functional tests |

| Infotainment Systems | Connectivity, display processing | Signal integrity, user scenario tests |

Takeaway: Automotive IC programming keeps vehicles connected, responsive, and, most importantly, safe. As automotive tech advances, there’s zero room for lagging standards.

3. Industrial and Medical Applications: Keeping Compliance and Quality on Point

When it comes to industrial and medical sectors, reliability and compliance are the name of the game. Malfunctions are out of the question here, especially in medical applications like pacemakers, diagnostic equipment, or industrial machinery used in high-stakes environments.

For medical devices, regulations demand that ICs operate with precision and align with stringent compliance requirements. For instance, in a pacemaker, ICs must manage sensitive data and maintain consistent functionality over long periods. Programming in these cases often includes safeguards like backup functions designed to kick in if primary operations encounter an issue. Medical manufacturers follow an exhaustive, step-by-step testing protocol to ensure each IC can handle regular operations as well as any unexpected conditions, keeping performance steady and reliable.

Example Table: Industrial and Medical Applications with Compliance Standards

| Application Type | IC Programming Requirements | Compliance Checks |

| Medical Devices (e.g., Pacemakers) | Redundancy, real-time monitoring | FDA compliance, burn-in testing |

| Industrial Equipment | Precision control, safety automation | OSHA compliance, operational tests |

| Diagnostic Equipment | Data accuracy, patient safety | EMC testing, failure mode analysis |

Takeaway: In fields where safety and precision are non-negotiable, IC programming is handled with extreme caution and care, ensuring reliability and upholding industry standards at every turn.

Why Choose Us?

JarnisTech takes the hassle out of IC programming, transforming a complex task into a streamlined process that boosts efficiency and trims costs in SMT assembly. We’ve got you covered with every standard socket commercially available—plus, if you need custom algorithms or specially designed sockets, we’ve got those dialed in too.

Our IC programming isn’t just about loading code. We make sure that each program is loaded precisely to your specs, right down to your choice of configurations, setup, and checksums. This means no surprises and no extra rounds of debugging on your end, just plug-and-play performance right off the production line.

1. Why Choose JarnisTech for IC Programming?

JarnisTech’s services go beyond standard IC programming, adding layers of reliability and customization so that you can focus on assembly without sweating the programming details. By handling IC programming with professional-grade precision, we let you skip the usual programming prep—no more sourcing sockets or dealing with incompatible setups.

With our expert setup, you can expect:

●Fast, reliable setup: We make sure every socket is prepped and ready for any configuration you need.

●Consistent quality checks: Every chip programmed undergoes thorough verification, so you know it’s done right the first time.

●Support for complex algorithms: We tackle both standard and custom algorithms, making it easy to handle unique programming requirements.

2. Case in Point: Cost and Efficiency Savings

By partnering with JarnisTech, our clients have cut programming-related delays, allowing SMT assembly to keep moving at full speed. One customer saw a 20% reduction in assembly line time and lower programming costs just by switching to our services, with fewer errors due to our precise checks and balances.

When you’re ready to eliminate the bottlenecks and boost your assembly efficiency, let JarnisTech be your go-to for IC programming. With a straightforward approach and reliable programming quality, we’re here to make sure your PCB assemblies don’t just work—they work perfectly every time.

Ready to make your PCB manufacturing and assembly smoother? Connect with JarnisTech today and bring simplicity to your programming process.

FAQ: IC Programming and PCB Assembly

What is IC Programming and its significance in PCB Assembly?

IC Programming customizes integrated circuits to enhance functionality in PCB Assembly, making it crucial for tailored electronic solutions.

What are the common programming techniques used in PCB Assembly?

Techniques include onboard programming, offboard programming, and flashing firmware, all of which optimize the performance of ICs in PCB Assembly.

What tools and equipment are essential for IC Programming in PCB Assembly?

Key tools include automated device programmers, flashers, and high-speed programming stations that improve efficiency and accuracy in PCB Assembly.

How does Design for Assembly (DFA) affect IC Programming in PCB Assembly?

DFA optimizes PCB layouts, making programming points more accessible and enhancing the overall efficiency of IC Programming during PCB Assembly.

What strategies can be employed for cost-effective IC Programming in PCB Assembly?

Effective strategies involve balancing cost with quality, selecting cost-effective components, and implementing batch programming techniques for mass production.

Advanced PCB Assembly

PCBs We Can Assemble

- Min size: PCB whose width/length is less than 30mm should be panelized.

- Max size: single board 500mm*400mm | panel board 310mm*410mm.

- Layer Count: 1-60 layers (1-20 layers for mass production).

- Copper Thickness: 1/2oz – 17oz.

- PCB Types: Rigid PCBs, Flex PCBs, Rigid Flex PCBs, Rogers PCBs, Ceramic PCBs, etc.

- Surface Finishes: Lead/Lead-free HASL, ENIG, ImSilver, OSP, Gold plated, Immersion Gold, etc.

Components We Can Assemble

- SMT sizes: 01005, 0201 or larger.

- BGA pitch: 0.35mm or greater.

- BGA Ball count: 2 – 50.

- Fine pitch: 0.4mm or greater.

- WLCSP pitch: 0.35mm or greater.

- Components Height: 0.1mm – 12mm.

- BGA, micro-BGA, POP, CSP, LGA package, Flip chip, Hard metric connectors, Cable & wire, etc.

- Min. Components Spacing: 0.20mm for SMT parts, no specific demand for Thru-hole parts.

Custom PCB Assembly Capabilities

- Quick Turn.

- IPC III standard compliant.

- Prototype Quantities to Production Quantities.

- Single PCB Assembly and PCB Panel Assembly.

- Single and Double-sided PCB Assembly.

- Leaded Assembly, Lead-free or RoHS Compliant Assembly and No-clean Process Assembly.

- SMT Assembly, Thru-hole (DIP) Assembly, and Combo of SMT and Thru-hole Assembly.

- Consigned PCB Assembly, Partial consigned PCB Assembly and Full turnkey PCB Assembly.