The field of illumination has undergone a significant revolution in recent years, thanks to the rapid advancements in lighting technology. Among the various options available, Light-Emitting Diodes (LEDs) have become increasingly popular due to their remarkable energy efficiency, durability, and versatility. At the heart of every high-efficiency LED light is the LED printed circuit board (PCB), which plays an essential role in driving growth and development in this sector.

JarnisTech recognizes the significance of the LED PCB and has established long-term collaborations with renowned LED lighting engineers worldwide to provide comprehensive manufacturing and assembly services. Our primary objective is to support and facilitate the evolution and development of our customers by offering top-notch services that meet their unique needs. We are committed to leveraging our expertise and resources to help our clients achieve their goals and stay ahead of the curve in this dynamic industry.

Introduction to LED PCB assembly

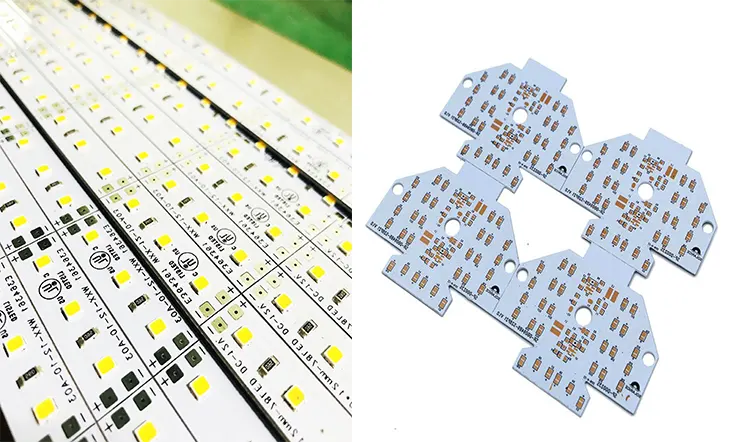

LED PCB assembly refers to the process of assembling electronic components on a printed circuit board (PCB) specifically designed for use with light-emitting diodes (LEDs). An LED PCB is a specialized type of PCB that is designed to provide electrical and mechanical support for LEDs. It typically has a metal or thermal conductive substrate, which helps to dissipate heat generated by the LEDs. LED PCBs can be single-sided, double-sided, or multilayered, depending on the complexity of the circuit and the number of LEDs required.

The assembly of an LED PCB involves the mounting and soldering of various electronic components, including LED chips, resistors, capacitors, diodes, and transistors, onto the PCB. The assembly process requires a high degree of precision and accuracy to ensure that the components are mounted correctly and the circuit functions as intended.

LED PCBs are used in a wide range of applications, including lighting, automotive, and consumer electronics. They offer several advantages over traditional lighting technologies, such as incandescent and fluorescent bulbs, including energy efficiency, longer lifespan, and lower maintenance costs. Additionally, LED PCBs can be designed to emit light in a specific direction, making them ideal for applications where directional lighting is required.

LED PCB Assembly Main Boards Types

LED PCB assembly main board is an important component of LED lighting systems. There are several types of LED PCB assembly main boards, including:

Single-layer LED PCB assembly main board: This type of PCB has only one layer of conductive material, making it simple and cost-effective to manufacture. However, it may not be suitable for complex LED lighting systems.

Double-layer LED PCB assembly main board: This type of PCB has two layers of conductive material, allowing for more complex circuit designs and better connectivity. It is commonly used in LED lighting systems that require more advanced features.

Multi-layer LED PCB assembly main board: This type of PCB has more than two layers of conductive material, allowing for even more complex circuit designs and higher connectivity. It is commonly used in high-end LED lighting systems that require advanced features and performance.

FR-4 (Flame Retardant-4): It is a widely utilized and cost-effective substrate material for LED PCBs. It consists of a laminate of glass fiber-reinforced epoxy resin, providing good electrical insulation and mechanical strength. FR-4 PCBs are suitable for low to medium-power LED applications that require cost-effective solutions.

Metal Core PCB (MCPCB): In contrast, high-power LED applications pose a significant challenge in terms of heat dissipation. Prolonged usage without proper heat dissipation can lead to circuit failures. To address this issue, MCPCBs are used, which incorporate metal materials such as aluminum, copper, or iron. Of these options, aluminum substrates are often preferred due to their favorable price-performance ratio. MCPCBs are suitable for medium power LED applications that require efficient thermal management but don’t generate excessively high levels of heat like high-power applications.

Flexible LED PCB assembly main board: This type of PCB is made of a flexible material, such as polyimide, that allows it to bend and conform to different shapes. It is commonly used in LED lighting systems that require flexibility and adaptability.

Aluminum LED PCB assembly main board: This type of PCB has a layer of aluminum on the bottom side, which provides better thermal conductivity and heat dissipation. It is commonly used in LED lighting systems that require high power and generate a lot of heat.

Ceramic LED PCB assembly main board: This type of PCB is made of ceramic material, which provides excellent thermal conductivity and high electrical insulation. It is commonly used in LED lighting systems that require high power and generate a lot of heat.

The selection of LED PCB assembly main board will depend on the specific requirements of the LED lighting system, such as power, size, shape, and thermal management needs.

Components of LED PCB Assembly

The components required for LED PCB assembly can vary depending on the specific application and design of the PCB, but typically include the following:

LED chips: These are the light-emitting diodes that produce light when an electrical current is applied to them. The LED chips are mounted on the PCB and are often arranged in a specific pattern to provide the desired lighting effect.

Resistors: These are electronic components that are used to limit the amount of electrical current flowing through the LEDs. They are typically used to protect the LEDs from damage due to over-current.

Capacitors: These are electronic components that store electrical energy and release it when required. Capacitors are often used in LED PCBs to smooth out voltage fluctuations and reduce electrical noise.

Diodes: These are electronic components that allow current to flow in only one direction. They are often used in LED PCBs to protect the LEDs from reverse voltage and prevent damage.

Transistors: These are electronic components that control the flow of electrical current in a circuit. They are often used in LED PCBs to switch the LEDs on and off, and to control their brightness.

In addition to these components, LED PCBs may also include other electronic components such as inductors, transformers, and integrated circuits, depending on the specific application and design requirements.

LED PCB Assembly Methods

When it comes to attaching electronic components, such as LED lamps, to printed circuit boards (PCBs), two primary assembly techniques are used: surface-mount and thru-hole assembly.

Surface-mount Assembly

Surface-mount assembly involves mounting components directly onto the board’s surface. This highly automated process offers excellent flexibility and allows for high connection densities, making it useful for LED applications. The process involves placing solder paste on the board, using a pick-and-place machine to place the components, heating the board to form the solder joints, and inspecting the board to ensure it functions correctly. Surface-mount LED circuit boards play a critical role in numerous applications, especially those that require complex circuitry in small devices.

Thru-hole Assembly

In contrast, thru-hole assembly involves drilling holes in the PCBs and running components, called leads, through these holes. The assembler then applies solder to hold the pieces in place. This process also involves multiple inspections to ensure accuracy and effectiveness. Thru-hole assembly provides stronger, more durable connections and is useful for equipment that will encounter more extreme environments and applications, such as high speeds or high temperatures.

In summary, both surface-mount and thru-hole assembly techniques have their advantages and are chosen based on the specific requirements of the LED application. The selection of the appropriate assembly technique is critical to ensure the reliable performance of LED circuit boards.

Assembly Process of LED PCB

The assembly process of an LED PCB typically involves the following steps:

Preparation: The first step in the assembly process is to prepare the necessary tools and materials. This includes the LED chips, resistors, capacitors, diodes, transistors, soldering iron, solder wire, flux, and a PCB holder.

Component placement: The components are then placed onto the PCB in their respective positions. The placement of the components is critical to ensure that the LED PCB functions as intended.

Soldering: Once the components are in place, they are soldered onto the PCB using a soldering iron and solder wire. Soldering involves heating the joint between the component and the PCB with the soldering iron and applying a small amount of solder wire to the joint.

Inspection: After soldering, the PCB is inspected to ensure that all the components are soldered correctly and there are no solder bridges or cold joints. Any defects are corrected at this stage.

Testing: The assembled LED PCB is then tested to ensure that it functions as intended. This involves applying power to the PCB and measuring the voltage and current to ensure that they are within the specified limits.

Final inspection: After testing, the PCB is inspected again to ensure that it meets all the design specifications and quality standards.

Packaging: The final step in the assembly process is to package the LED PCB for shipping or installation. The PCB is typically placed in an anti-static bag or container to protect it from damage during transportation.

Advantages and Disadvantages of LED PCB Assembly

Advantages of LED PCB assembly:

Energy efficiency: LED PCBs are more energy-efficient than traditional lighting technologies, such as incandescent and fluorescent bulbs. They consume less power and emit less heat, making them more environmentally friendly.

Longer lifespan: LED PCBs have a longer lifespan than traditional lighting technologies, which can save on maintenance and replacement costs over time.

Design flexibility: LED PCBs can be designed to emit light in a specific direction, making them ideal for applications where directional lighting is required. They can also be designed in a variety of shapes and sizes to suit different applications.

Durability: LED PCBs are more durable than traditional lighting technologies and are less prone to damage from shock and vibration.

Cost-effective: LED PCBs may have a higher upfront cost compared to traditional lighting technologies, but they can save on energy and maintenance costs over time.

Disadvantages of LED PCB assembly:

Complexity: LED PCB assembly can be a complex process that requires skilled labor and specialized equipment. This can increase the cost and time required for assembly.

Heat dissipation: LED PCBs generate heat that needs to be dissipated to prevent damage to the components. This can require the use of additional heat sinks or fans, increasing the cost and complexity of the design.

Color consistency: LED PCBs may have variations in color consistency due to differences in manufacturing processes and component quality.

Blue light hazard: LED PCBs emit blue light, which can have harmful effects on the eyes if exposure is prolonged. This can be mitigated by using filters or diffusers, but this can increase the cost and complexity of the design.

Environmental concerns: LED PCBs can contain hazardous materials, such as lead and mercury, which can be harmful to the environment if not disposed of properly.

Some Requirements For Custom LED Lighting

When working on custom LED lighting, attention to detail is crucial as the work is sensitive. PCB assembly, in particular, is gaining popularity, and with lights becoming smaller, perfection is essential. To create proper custom LED lighting, the following factors are necessary:

1. Expertise in LED Lighting PCB assembly is critical because even a small mistake can cause the PCB to stop working or lead to a short circuit.

2. High-quality soldering materials are necessary to ensure that the work is neat and free of errors.

3. Quality documentation is necessary to custom make a durable and stable PCB lighting.

4. Due to the high heat generated during the assembly process, protective measures are necessary to ensure precise results.

5. Knowledge of lighting and the growing technology is essential. Proper education ensures that one stays up to date with technological advancements and can make necessary changes or improvements at any time.

Therefore, creating custom LED lighting requires attention to detail and proper knowledge of LED Lighting PCB assembly. High-quality materials, protective measures, and up-to-date knowledge of lighting technology are necessary to ensure that the work is precise, error-free, durable, and stable.

Professional LED PCB Assembly Supplier

JarnisTech is a leading supplier of PCB assembly services, with almost two decades of experience in the field. Our extensive expertise and rich experience have earned us the trust of customers from various industries, including smart agriculture, commercial, and medical. We offer customized LED PCB assembly solutions, covering LED PCB design, prototyping, manufacturing, assembly, and testing. Our one-stop service enables us to deliver products quickly to customers while maintaining quality, helping them enter the market faster.

At JarnisTech, we specialize in ODM/OEM LED PCB assembly, OEM LED control PCBA, and OEM LED driver PCBA. Our capabilities include hardware and firmware design, iOS/Android APP development, and plastic molding. We also provide OEM services based on Gerber files and BOM lists, or we can design products based on customers’ requirements.

Moreover, we produce a broad range of LED PCBA products, including UV LED PCBA for medical machines and 3D printers, AC220V and AC110V no driver LED PCBA, street light LED PCBA, tube light LED PCBA, panel LED PCBA light, COB RGB LED PCBA for pool lights, RGB LED PCBA for pixel lights, LED PCBA for ceiling lights, LED PCBA for traffic lights, and many more.

All in All, JarnisTech provides comprehensive PCB assembly services, including customized LED PCB assembly solutions, hardware and firmware design, and OEM services. Our wide range of LED PCBA products serves various industries and applications, and our one-stop service ensures that we deliver high-quality products to customers quickly.

Future Trends in LED PCB Assembly

There are several future trends in LED PCB assembly that are likely to shape the industry in the coming years:

Miniaturization: The trend towards smaller and more compact electronic devices is expected to continue, driving demand for smaller and more densely packed LED PCBs.

Higher efficiency: LED PCBs are already highly efficient, but there is still room for improvement. Advances in materials science and manufacturing processes are expected to lead to even greater energy efficiency in the future.

Integration with other technologies: LED PCBs are increasingly being integrated with other technologies, such as sensors, wireless communication, and artificial intelligence. This trend is expected to continue, enabling new applications and use cases.

Smart lighting: LED PCBs are well-suited for smart lighting applications, and advances in sensors and wireless communication are expected to drive the development of even more sophisticated and intuitive smart lighting systems.

Sustainability: Environmental concerns are becoming increasingly important, and LED PCB manufacturers are likely to focus on reducing the environmental impact of their products. This may include the use of more sustainable materials, reducing waste and energy consumption during manufacturing, and improving the recyclability of LED PCBs at the end of their lifespan.

Overall, the future of LED PCB assembly is likely to be characterized by continued innovation and technological advancement, driven by demand for more efficient, versatile, and sustainable lighting solutions.

Summary

Over time, PCBs have become increasingly sophisticated, featuring smaller sizes, multiple layers, and intricate designs that differ greatly from their predecessors. The resulting efficiency has made it possible to create slimmer and faster devices for a range of applications. Choosing the right partner to work with can save time and money, and JarnisTech is ready to meet your needs.

With years of experience producing PCBs for LED lighting and relevant certification, JarnisTech is a trusted provider of high-quality custom LED circuit boards. Our team works around the clock to ensure that our customers receive the best possible products and services. Contact us today to learn more about our capabilities and how we can help you achieve your goals.