The term “PI” refers to a specific type of polyimide resin material, which is a material that has very good performance and is being utilized in a variety of industries due to its widespread applicability. Some people consider PI to be a ground-breaking substance that has the potential to foster the reform of electronic devices. In addition, PI is a material that has a very good high temperature resistance, and it can be used in both the aerospace technology business and the medical industry.

If you are interested in the PI in FPC Circuit Boards and would like to learn more about it from a more professional standpoint, please check out and read the content below.

What Is Polyimide(PI) in FPC?

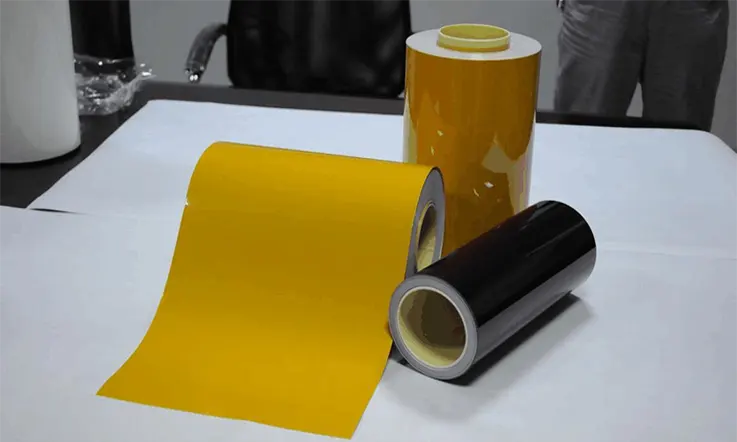

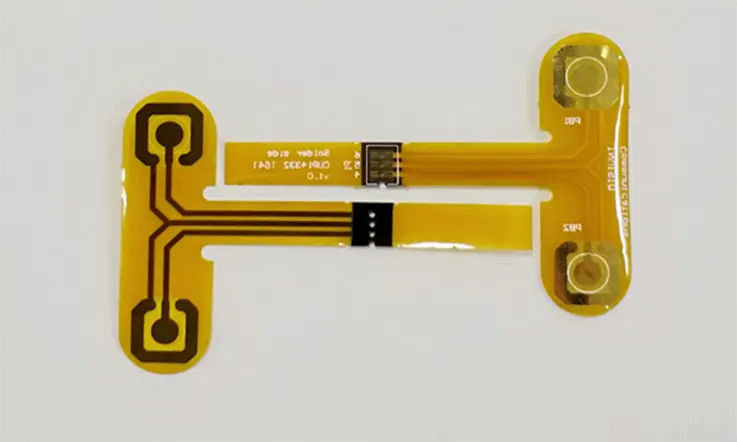

PI stands for polyimide. It is a form of organic polymer material that is capable of withstanding high temperatures while maintaining its flexibility. This is the major material that is utilized when the production of Flex circuit boards takes place. It is common knowledge that the material possesses a wide range of features, one of which is an exceptional resistance to wear and heat; in addition, it is perfect for use in insulating devices. PI is most commonly seen as a yellow tint, although it also comes in black, white, and even transparent varieties. Because it increases both repeatability and flexibility, PI is a vital component of FPC circuit boards.

One of the components that make up FPC is called PI, and it is reliant on polyimide (PI). The pliability of flexible circuit boards can be attributed to the presence of PI, which is an organic chemical. A line width of 2.75 mils can be found on an Flex PCB. It is an extremely important component in mobile phones, as well as in many other types of industrial settings. The pliability of the material makes it possible to quickly and easily connect components like buttons, batteries, and microphones. In addition, the led light and engine control sensors are also extremely important components in the car sector.

A flexible printed circuit board, often known as an FPC, is a type of printed circuit board. The PI material is extremely bendable, thus it may be folded and bent without breaking. In addition to this, it is capable of superior heat dissipation than a conventional printed circuit board (PCB), which can assist prolong the life of electronic components. Additionally, as a result of its flexibility, it is feasible for producers of electrical components to bend and shape it in any way they see fit; in fact, they are exploring incorporating this capability into future smartphones.

Polyimide’s Types

There are numerous varieties of polyimide, each of which possesses its own set of distinguishing qualities and qualities. The following are types of some of the most prevalent forms of polyimide:

● Thermosetting Polyimide: This type of polyimide has cross-linked molecules that make it highly resistant to heat, chemicals, and radiation.

● Thermoplastic Polyimide: This type can be melted and reformed multiple times without losing its properties. It is less heat resistant than thermosetting polyimide and is commonly used as a coating or film.

● Semi-crystalline Polyimide: This type has a partially ordered molecular structure and is known for its high stiffness and strength. It is commonly used in aerospace and defense applications.

● Amorphous Polyimide: This type has a disordered molecular structure and is highly flexible and transparent. It is commonly used in electronic and optical applications.

Properties of Polyimide(PI)

The following is a list of important characteristics of polyimides:

● Low Coefficient of Friction: Because of their low coefficient of friction, polyimides are appropriate for use in applications that call for minimal friction.

● High Strength and Toughness: Polyimides are a robust and abrasion-resistant material because of their high modulus of elasticity and great resistance to impact.

● Good Chemical Resistance: Because polyimides are resistant to a broad variety of chemicals, including acids, bases, and organic solvents, they are an excellent option for usage in conditions that are particularly hostile.

● Heat resistance: Since polyimides have a high melting temperature and are resistant to thermal deterioration, they are ideally suited for use in applications that involve temperatures that are particularly high.

● Weather Resistant: Due to their resistance to weathering, polyimides are appropriate for use in outdoor applications.

● UV Resistant: Because polyimides are unaffected by the sun’s ultraviolet (UV) rays, they can be utilized in a variety of applications that take place outside.

Polyimide is a versatile material that is utilized in a wide variety of applications since it is a viable choice due to its outstanding mechanical and thermal properties, as well as its superior chemical resistance and low coefficient of friction.

Limitations of Polyimides

● Has high manufacturing cost.

● Sensitive to alkali and acid attacks.

● High temperature requirement in the processing.

● Specified operating procedures, including annealing processes at specified temperatures.

However, designing and synthesizing polyimide matrix for high-temperature composite components can be challenging. This is because the matrix resins must not only have adequate thermal and mechanical properties, but also appropriate melt processability in order to meet the requirements of the composite components.

Applications of PI

Excellent mechanical and thermal qualities, as well as outstanding chemical resistance, distinguish polyimide as a high performance polymer. Because of these characteristics, it can be used in the microwave and aircraft sectors.

In the aerospace industry, components that are subjected to severe conditions, such as high temperatures, intense pressures, and harsh chemicals, are manufactured with polyimide as the material of choice. It is a perfect choice for these applications as a result of its strong mechanical and thermal qualities, as well as its good resistance to chemical degradation. Due to its great strength and toughness, as well as its capacity to tolerate extreme temperatures and pressures, polyimide is frequently utilized in the fabrication of aviation components. These components include structural elements, seals, and gaskets.

Polyimide is a material that is put to use in the manufacturing of components that are utilized in the microwave industry. These components are subjected to high temperatures as well as high frequency electromagnetic radiation. These applications are a good fit for the material because of the strong thermal qualities and the good chemical resistance it possesses. As a material that is resistant to both high temperatures and high frequencies of electromagnetic radiation, polyimide is frequently utilized in the manufacturing of microwave components such as microwave ovens, microwave filters, and other microwave components.

Polyimide is a versatile material that is used in a wide range of applications because of its outstanding mechanical and thermal qualities, as well as its superior chemical resistance and low coefficient of friction. These characteristics make it a great choice for the application.

Polyimide(PI) and FPC Circuit Board Relationship

As Covering Film: The PI has numerous features, including the ability to tolerate high temperatures, as well as being great in wear resistance and insulation, and the single-layer PI is incredibly thin. As a result of this, PI is frequently utilized as the protective film in the location where the gold finger is utilized on the circuit board. The primary reason for this is that the gold finger requires a large number of connectors to be embedded for a variable number of times. If an ordinary covering film is used for an extended period of time, it is very likely that the gold finger will become damaged.

As FPC Base Plate: The majority of circuit boards are made from this material. Because the copper foil of the circuit board is so thin, it is insufficient to support the adhesive and covering film by itself, the substrate serves primarily as a reinforcement and a thickener. In this position, PI has primarily the thickness of multilayer PI for lamination, and singlelayer PI is also extremely thin.

Not only is PI one of the substrate materials, but so are PET, FR4, ET, etc. However, due to the impact of material contraction during the production of flexible boards, PI is typically used as the insulating material in the production of FPC flexible circuit boards for the sake of production yield and efficiency, unless the customer specifically requests another material.

Summary

As a result of the exceptional qualities it possesses, polyimide is one of the most common materials utilized in the production of both flexible and rigid printed circuit boards (PCB and FPC respectively). In a nutshell, polyimide is a polymer that is indispensable in many different industries, including the automotive, aerospace, electronic, and medical fields.In light of this, if your PCB project requires polyimide, please get in touch with us by sending an email. We will supply you with a professional engineer team that will assist you in finding a solution to your question. In addition, as a PCB manufacturer in China with a wealth of knowledge under our belts, we not only provide pcb manufacturing and the acquisition of components, but we also offer a Full Turnkey PCB assembly Service.