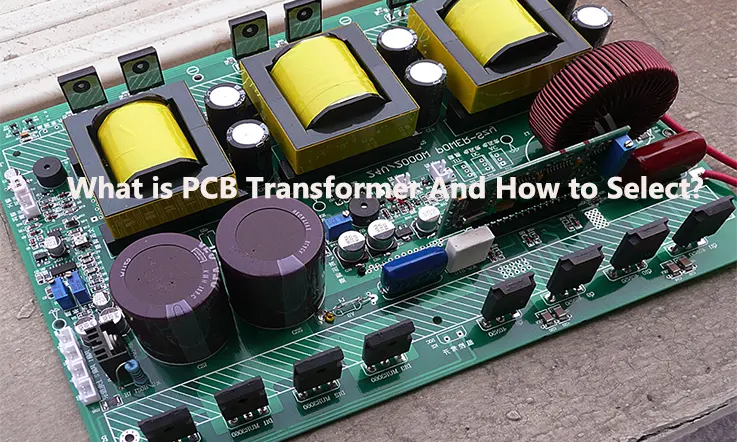

Transformers are integral components in PCBs, and selecting the right transformer depends on the specific requirements and applications of the PCB. This article aims to highlight the key features of PCB-mounted transformers that aid in identifying the optimal transformer for your needs.

PCB-mounted transformers are designed to be compact and lightweight while still being able to handle heavy loads. When considering a transformer for your device, it is crucial to take several important factors into account. In the following sections, we will delve into the intricate details of transformers, including their various types, notable features, and functional aspects.

What are PCB Transformers?

PCB transformers are manufactured using vacuum molding techniques, resulting in a robust construction with a remarkably high proof voltage capability. When employed on a PCB, these transformers serve multiple purposes, such as providing electrical isolation as a power transformer or ensuring safe isolation between the input and output sides as an isolating or safety transformer.

Transformers play a crucial role as electrical components, facilitating the transfer of electrical power from one section of a circuit to another. They offer a multitude of benefits and features for devices. One notable advantage is their ability to isolate the device from the power source, effectively disconnecting its connection from the ground. This serves as a safety measure, preventing accidental contact with exposed wires. Furthermore, transformers enable the conversion of current and voltage levels without adversely affecting the power output. By incorporating transformers into the power supply, this conversion can be achieved. Additionally, transformers contribute to amplifying the input waveform and converting electrical signals to appropriate current and voltage levels for individual devices.

PCB-mount transformers, as their name suggests, are transformers designed to be mounted directly onto the surface of circuit boards. They are indispensable electrical components, particularly beneficial for PCBs that operate on low power consumption. The inclusion of transformers helps amplify signals and enhance the electrical power within the PCB, optimizing its overall performance.

How Do PCB Transformers Work?

PCB transformers, also known as printed circuit board transformers, are electronic components used to transfer electrical energy between circuits through magnetic coupling. They work based on the principles of electromagnetic induction.

Here’s a simplified explanation of how PCB transformers work:

1. Primary and Secondary Windings: A PCB transformer consists of two or more insulated wire windings, known as the primary and secondary windings. These windings are typically wound around a magnetic core.

2. Magnetic Field Induction: When an alternating current (AC) is applied to the primary winding, it creates a changing magnetic field around the winding. This changing magnetic field induces an alternating voltage in the secondary winding due to electromagnetic induction.

3. Turns Ratio: The turns ratio of a transformer determines the voltage transformation ratio between the primary and secondary windings. It is defined as the ratio of the number of turns in the primary winding to the number of turns in the secondary winding. By adjusting the turns ratio, the voltage can be stepped up or stepped down.

4. Energy Transfer: As the alternating voltage is induced in the secondary winding, it can be used to power another circuit or device. The energy transfer occurs through the magnetic field coupling between the primary and secondary windings.

5. Efficiency and Impedance Matching: PCB transformers are designed to have high efficiency, minimizing energy losses during the transformation process. They also provide impedance matching between the source and load circuits, ensuring maximum power transfer.

PCB transformers are commonly used in various applications, such as power supplies, audio amplifiers, signal isolation, impedance matching, and voltage level conversion. They play a crucial role in electrical systems by enabling efficient and reliable transfer of electrical energy between different circuits.

Composition of Transformer PCBs

Each PCB transformer comprises two essential types of coils: the primary coil and the secondary coil. These coils are meticulously crafted from copper wire, tightly wound around the magnetic core. The magnetic core itself is typically composed of metal alloys such as steel or other suitable materials. Additionally, transformers feature outer casings and terminals, ensuring proper insulation and connection.

When it comes to incorporating transformers onto PCBs, two distinct mounting techniques are commonly employed:

Surface Mounted:

This method involves using solder paste and soldering techniques to directly attach the transformer onto the surface of the PCB. However, it is important to note that in environments with harsh conditions or elevated temperatures, there is a possibility of the solder paste becoming loose, potentially compromising the reliability of the connection.

Through Hole:

In this approach, holes are drilled on the PCB, and leads are inserted through these holes. This allows for the transformer to be soldered using through-holes on both sides of the PCB, ensuring a secure and robust connection.

Both mounting techniques have their advantages and considerations, and the choice between them depends on factors such as the specific requirements of the PCB, environmental conditions, and manufacturing considerations.

Specifications of Transformer PCBs

PCB transformers possess various specifications that warrant careful consideration. These factors include:

Primary and Secondary Ratings:

These ratings denote the current and voltage levels between the primary and secondary coils. It is important to assess the output voltage value and compare it with the design requirements. Additionally, evaluating the current value and ensuring it aligns with the intended design is crucial. Furthermore, considering power density is essential as it aids in dissipating heat from the PCB effectively.

Power Rating and Efficiency:

The power rating indicates the type of current, whether it is DC or AC, and determines the transformer’s capacity to handle power. It is also important to consider the voltage frequency. Power efficiency is another significant factor as it determines the transformer’s effectiveness under light loads.

Form Factor:

Transformers can be designed to be vertically oriented or flat on the surface of the board. While vertical transformers may save space on the board, they can be more susceptible to vibrations.

Mounting Style:

It is crucial to determine the type of transformer required. Surface Mount Technology (SMT) transformers require soldering techniques for integration onto the board. Through-Hole Technology (THT) transformers, on the other hand, necessitate drilling holes and passing leads through them before soldering the transformer on the opposite side of the PCB. THT transformers often offer greater heat resistance.

Cooling Mechanism:

PCB-mount transformers typically consume less power, resulting in lower heat generation. This often eliminates the need for external cooling systems. In certain cases, planar PCB transformers can incorporate heat-dissipating sinks to enhance thermal management.

Inductance:

Inductance refers to the efficiency with which a transformer establishes a connection between two circuits. While inductance is generally associated with DC-DC converter PCBs, power efficiency plays a crucial role in determining the performance and simplicity of transformer coupling.

Considering these specifications ensures the selection of a PCB transformer that meets the specific requirements of the application and optimizes its performance.

Types of PCB Mount Transformers

Various types of transformers are available, each with a specific form factor suitable for mounting on a computer board. Here are some notable types:

Audio Transformers:

Designed for voice and data transmission, these transformers exhibit a frequency response typically ranging from 300 Hz to 20 kHz.

Autotransformers:

These special power transformers feature a single winding. By tapping or connecting at specific points along the winding, different voltage levels can be obtained. Autotransformers find applications in low-power scenarios.

Balun Transformers:

Balun transformers facilitate the interface between balanced lines (two conductors carrying equal currents in opposite directions) and unbalanced lines (a single conductor carrying current and a ground). Their name derives from the terms “BALanced to UNbalanced lines.”

Current Sense Transformers:

These transformers are primarily used for current detection and measurement. There are two main types: precision current sense transformers employed in accurate instrumentation applications, and those used in switch-mode power converter applications.

Flyback Transformers (FBT) or Line Output Transformers (LOPT):

Flyback transformers are designed to generate a high output voltage (often in the kilovolt range) from a relatively low input voltage. They utilize the flyback or kickback of an inductor to convert the input voltage to the desired output voltage. Flyback transformers are commonly used to generate high voltages for driving CRTs (Cathode Ray Tubes).

Interface Transformers:

These transformers find application in communication systems where signal isolation is necessary.

Lighting Transformers:

Lighting transformers are employed to provide suitable power to lights and lighting systems.

Medical Transformers:

Used in medical equipment, such as biomedical devices in hospitals, medical transformers must adhere to strict safety regulations, guidelines, and laws governing their design, construction, and usage.

Power Transformers:

Power transformers convert voltage levels at high power levels. They are extensively utilized in electronic circuits, offering various types and applications. Power transformers, typically rated at 300 volt-amperes and below, often supply power to electronic devices’ power supplies, such as power amplifiers in audio receivers.

RF Transformers:

These low-power devices are primarily used for impedance matching in the radio frequency or microwave spectrum.

Resonant Transformers:

Operating at the resonant frequency of either the primary or secondary coil, resonant transformers find application in arc welding, discharge lamps, and similar applications.

Switch Mode Transformers or Switching Transformers:

These transformers play a vital role in switching power supplies and DC-DC converters. They serve as the energy storage element for transferring energy from input to output in discrete packets, as required in switching power supplies, regulators, or converters.

These diverse transformer types cater to specific needs and applications, enabling efficient and reliable performance in various electronic systems.

How to Select the Right PCB Transformer?

Before purchasing a PCB transformer, several factors should be considered, including voltage rating, current rating, type of core, and type of winding.

Voltage Rating:

The voltage rating of a PCB transformer signifies the maximum voltage that can be applied across its terminals. Transformers are available in various voltage ratings to accommodate different application requirements.

Current Rating:

The current rating of a PCB transformer indicates the maximum current it can safely handle. Transformers are designed to support different current ratings, allowing for optimal performance and safety in specific applications.

Type of Core:

Transformers are available with different types of cores, chosen based on the application and voltage rating. Common core types include laminated iron cores, ferrite cores, and toroidal cores. Each core type offers specific benefits in terms of magnetic properties, size, weight, and cost.

Type of Winding:

PCB transformers can have single or three-phase windings. Single-phase transformers are commonly used in applications with a single-phase power supply, while three-phase transformers are employed in systems with three-phase power. The selection of the winding type depends on the specific power requirements and system configuration.

Considering these factors ensures the appropriate selection of a PCB transformer that aligns with the voltage and current requirements of the application, while also considering the core type and winding configuration for optimal performance and compatibility.

Why Choose JarnisTech for Your Transformer PCB

With over 20 years of experience, JarnisTech has established itself as a specialized provider of transformer PCB design, manufacturing, and assembly services. Renowned as a prominent transformer PCB manufacturer in China, we pride ourselves on employing state-of-the-art technology to create customized transformer PCBs that meet your exact specifications. Our expansive production facility enables us to deliver high volumes of transformer PCBs and other PCB assemblies to fulfill your requirements.

At JarnisTech, we are dedicated to assisting you with your unique project. Our team comprises industry experts with extensive knowledge in the PCB field. We maintain a comprehensive inventory of standard transformer PCBs in our facility, readily available for prompt delivery to your desired location. Prior to dispatch, each transformer PCB undergoes rigorous quality control measures and inspections to ensure impeccable performance and reliability.

For further information or inquiries, please do not hesitate to reach out to us. We are eager to provide you with exceptional service and support for your transformer PCB needs. Contact us now to explore how we can assist you in achieving your goals.

Summary

In summary, this article provided an overview of PCB-mounted transformers, offering a concise understanding of their components and the electromagnetic principles underlying their operation. It also offered guidance on selecting an appropriate transformer for PCB integration. Additionally, the article distinguished various types of transformers and highlighted their primary applications.

It is important to note that this article aimed to provide fundamental information about PCB transformers. There is a wealth of knowledge to explore regarding non-PCB transformer devices and their diverse applications. Nonetheless, we trust that this article has been informative and beneficial to you.

If you have any further questions or require additional information, please don’t hesitate to reach out. We are here to assist you in any way we can.