Resistors hold a crucial position in the realm of electronic circuits, serving as fundamental components in both analog and digital circuitry. Their absence would impede the proper functioning of various devices, such as computers, smartphones, and numerous other everyday gadgets. Given the substantial impact of resistor values on electronic systems, it becomes imperative for beginners to grasp the significance of different resistor types and their appropriate implementation. Thus, presented herein is a comprehensive guide elucidating the various aspects of PCB resistors, encompassing their indispensability and optimal utilization.

What is a PCB Resistor?

A PCB resistor is an electronic component designed to transform electrical energy into heat. It consists of two terminals, one connected to the positive side of the circuit, and the other connected to the ground. Upon the application of voltage across the resistor, current passes through it, generating heat proportionate to the voltage difference.

The primary objective of utilizing PCB resistors is to regulate the flow of current by dissipating the resulting heat across their resistive value. This prevents the current from directly heating the components or causing damage due to overheating.

Resistor Material Types

Resistors can be categorized based on the materials employed in their construction, which include carbon, metal oxide film, wire wound, and others. The selection of resistor material is contingent upon its intended application. While economical resistors exist, they may exhibit lower efficiency. On the other hand, printed circuit boards requiring a high degree of precision necessitate the use of higher-quality resistors.

Carbon composition, once prevalent, has become infrequently utilized in modern devices. This is attributable to the advent of superior and more cost-effective resistor types. Moreover, carbon composition resistors offer relatively low precision and find application in scenarios involving high-energy electrical pulses.

Wire wound resistors, the oldest resistor material, continue to be employed in contemporary devices. Its suitability lies in high-power applications, owing to its precise resistance. Despite its low resistance values, this age-old resistor material maintains a commendable level of reliability.

Metal film resistors, featuring stable resistance and tolerance, enjoy extensive usage in the present era. These resistors exhibit minimal reactivity to temperature variations.

Metal oxide film, another commonly employed resistor material, incorporates a protective coating of conformal epoxy resin. This material showcases a high-temperature coefficient, contributing to its popularity.

Carbon film, originating during the transistor technology era, is characterized by low power consumption and high inductivity. These resistors are safeguarded by a conformal epoxy coating, ensuring their durability and performance.

Types of Resistors

Various types of resistors can be distinguished based on their characteristics and applications.

Fixed value resistors maintain a constant tolerance and resistance, unaffected by factors such as light and temperature. They are widely utilized and serve as the predominant resistor type on printed circuit boards.

Variable resistors, as the name suggests, possess adjustable resistance. They allow for modification of resistance through mechanisms such as potentiometers, which feature a dial for increasing or decreasing resistance.

Physical quality resistors exhibit resistance variations in response to specific physical properties such as light levels, temperature fluctuations, or magnetic fields. Examples of physical quality resistors include varistors, thermistors, and photoresistors.

Through hole resistors are equipped with leads on either end, which are bent for insertion and soldering into the holes of a PCB. They come in various dimensions in terms of height, length, and width. Through hole resistors are often color-coded with bands to indicate their tolerance and resistance values. They are commonly employed in prototyping and breadboarding applications. However, they occupy more space and typically come in axial packages.

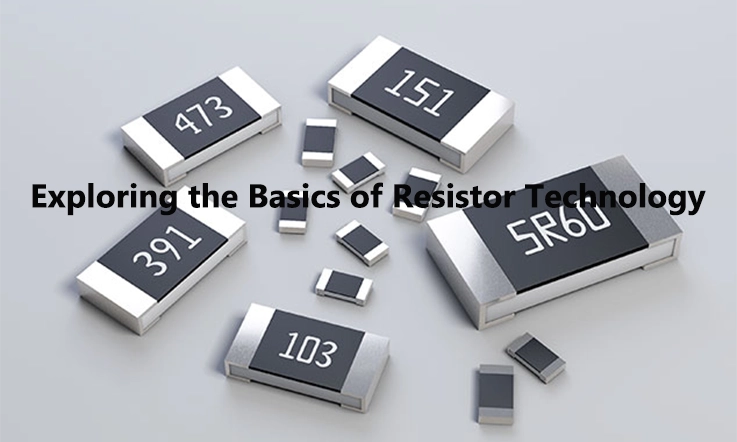

Surface mount resistors, on the other hand, are small-sized components soldered directly onto metal pads on the PCB. They are more compact than through hole resistors and take up less space. The tolerances and values of surface mount technology (SMT) resistors are typically marked or stamped on the components themselves.

Functions Of Resistor

In the realm of printed circuit boards and electronic devices, resistors, symbolized by the letter “R,” fulfill several important functions. These functions encompass:

Voltage division: When combined with other components such as bulbs, resistors facilitate voltage division. By appropriately configuring the resistor and bulb voltages in relation to the total voltage across the circuit, the resistor effectively divides the voltage.

Impedance matching: Resistors play a crucial role in impedance matching, which involves adjusting the load impedance to align with the internal impedance of the excitation source. This matching ensures maximum power output during signal transmission and allows for the modification of impedance as needed.

Voltage drop: Resistor components enable the creation of specific voltage levels by facilitating voltage drop. Electrical elements within a circuit require precise voltage levels, and resistors contribute to achieving this requirement.

Current limitation: Resistors are instrumental in limiting the flow of electric current by reducing its magnitude. By regulating the current, these electrical components determine the amount of current that can flow for a given voltage, effectively delimiting the flow of electrons.

Data and address bus pull-ups: Resistors are employed for noise reduction in high-speed computer buses. By utilizing pull-up resistors on data and address buses, potential noise interference is minimized. Additionally, when a data bus tri-states, it is necessary to pull it into a known state to ensure that the output remains consistently high during switching.

Powering LEDs: To prevent excessive current from damaging light emitting diodes (LEDs), resistors are used in conjunction with LEDs. By connecting a resistor in series with an LED, the resistor regulates the amount of current supplied to the LED, safeguarding it from burnout.

These diverse functions highlight the significant role that resistors play in various aspects of electronic circuitry and their ability to control and modulate electrical parameters.

How the Resistor Work?

A resistor plays a crucial role in collecting electrical energy while simultaneously impeding the flow of current and reducing voltage. The dissipation of this collected energy occurs in the form of heat. In modern electronic circuits, the heat transfer associated with resistors is typically minimal, often measuring less than 1µW (microwatt).

Ohm’s law establishes a fundamental relationship between resistance (R), current flow (I), and voltage drop (V) in a circuit. According to Ohm’s law:

V = I / R

This equation signifies that a resistor with a value of 1 ohm will allow a current flow of 1 ampere when there is a voltage difference of 1 volt across its terminals.

In a direct current (DC) circuit, the power output (W) of a resistor can be expressed using the equation:

W = V * I

This equation demonstrates that power (watts) can be calculated by multiplying the current (I) and voltage (V) values. Watts can also be expressed in terms of resistance (R) and current (I) by utilizing Ohm’s law:

W=I2/R

Similarly, watts can be expressed in terms of voltage (V) and resistance (R):

W=V2*R

These alternative equations can be useful in situations where the current or voltage drop is unknown or needs to be determined.

When alternating current (AC) is employed, similar relationships exist. However, due to the nature of AC, the voltage becomes a more complex function of the resistance, requiring additional considerations in the analysis of AC circuits.

How to Test PCB Resistors?

To determine the value of a resistor, a multimeter is commonly used. It is a versatile tool that can provide resistance measurements. However, it should be noted that the readings obtained may vary depending on the specific multimeter being used and its settings.

Another method to test resistors involves utilizing a PCB breadboard, which offers a hands-on approach. Here’s a step-by-step guide:

1. Cut a piece of wire that is long enough to reach from one end of the resistor to the other.

2. Strip the ends of both wires and insert them into the breadboard, ensuring they are securely connected.

3. Apply a few drops of water on each lead, allowing it to flow into the holes on the breadboard.

4. The wires should be connected to the resistor and ground, respectively.

5. Place a voltmeter between the two wires to test the flow of electricity through them and the water.

6. If everything is functioning correctly, the voltmeter should display a reading of 0 volts or a value very close to it.

It is important to exercise caution when working with electrical components and to follow safety guidelines to prevent any accidents or damage.

How to Understand PCB Resistor Code?

Surface mount resistors (commonly found on PCBs) are often marked with numerical codes, which are used to denote their resistance values. These codes follow a standard system, similar to how color bands are used with through-hole resistors. However, the specifics of the system can vary depending on the size and type of the resistor.

Here’s a quick guide to understanding these codes:

Three-digit code (Standard SMD Resistor):

The three-digit code is typically used for standard-sized SMD resistors. The first two digits represent significant figures, and the third digit indicates the multiplier (the power of 10 to which the first two digits should be multiplied). For example, a resistor marked “473” would have a resistance of 47 x 10^3 ohms = 47 KΩ.

Four-digit code (Precision SMD Resistor):

Some SMD resistors use a four-digit code, which offers greater precision. It works the same way as the three-digit system, but with three significant figures followed by a multiplier. For example, a resistor marked “4702” would have a resistance of 470 x 10^2 ohms = 47 KΩ.

EIA-96 code (Precision SMD Resistor):

Some precision SMD resistors use the EIA-96 coding system. This uses a three-digit code where the first two digits are a code that represents a 3-digit number with two significant figures, and the third digit is a multiplier. The EIA-96 code is more complex and requires a lookup table to understand.

No Code (Small SMD Resistor):

Very small SMD resistors often have no code due to space constraints. The resistance of these resistors must be determined using a multimeter or by consulting the documentation.

Please note that these are just general guidelines. There are exceptions, and different manufacturers may use different systems. Always refer to the manufacturer’s documentation when in doubt.

Also, keep in mind that resistors have a tolerance, meaning the actual resistance could be slightly higher or lower than the marked value. This tolerance is usually indicated in the datasheet for the specific component.

How to Identify the Resistor on the PCB Board?

The most prevalent approach for identifying a resistor on a PCB board involves utilizing a multimeter. When conducting PCBA testing and aiming to identify the specific resistor, it is necessary to connect the jumper wire to the resistor and make the appropriate adjustments to the multimeter’s settings. Typically, the multimeter’s dials need to be adjusted to display a reading of 0 volts, which corresponds to the normal operating range of the meter. Some multimeters also provide indicators that help determine the accuracy of the displayed reading, and it is advisable to consult these indicators as needed. By employing the multimeter in this manner, one can effectively identify the resistor on the PCB board during the testing process.

How to Solder Resistor on PCB?

The process of soldering a resistor onto a PCB typically involves three key steps:

Selection of soldering materials:

When soldering a resistor on a PCB, it is essential to gather the necessary soldering materials. These commonly include a soldering iron, solder wick, and a solder sucker. The soldering iron consists of a handle and a heating element, usually made of rubber or other nonconductive materials. The solder wick, also known as desoldering braid, helps in removing excess solder. A solder sucker is a useful tool for efficiently extracting solder residue during desoldering operations.

Soldering preparation:

Prior to soldering, it is crucial to ensure the cleanliness of the PCB. The soldering iron needs to be adequately heated to maintain the appropriate temperature for soldering. Creating a designated workspace is also important, which may involve using a moistened sponge as a resting place for the soldering iron stand. Additionally, the soldering iron tip should be coated and cleaned to enhance its performance during soldering.

Soldering process:

The actual soldering process for attaching the resistor to the PCB consists of several steps. Initially, surface preparation is vital to ensure a clean board surface, promoting low resistance and strong solder joints. Next, the resistor is carefully placed onto the designated area on the PCB. It is advisable to begin with smaller components and gradually add larger components, ensuring sufficient space and stability during the soldering process. Heat is then applied to the soldering iron’s tip, allowing the conduction of heat to the board and other components. Finally, solder is applied to the joints, and it is crucial to verify that the solder is correctly placed and forms satisfactory joints.

By following these steps, one can effectively solder a resistor onto a PCB, ensuring reliable electrical connections and optimal performance.

Functions of Embedded Resistors in Hi-speed Circuit Boards

High-speed PCBs have become ubiquitous in various industries, finding applications in devices such as smartphones, military radars, and medical equipment. These PCBs play a critical role in enabling the functionality of electronic systems. In the past, printed circuits primarily consisted of simplified integrated circuits (ICs) comprising a resistor and a few transistors.

While this simplistic design sufficed for electronics with limited functionality, technological advancements demanded higher performance. One significant challenge faced by PCB manufacturers was the miniaturization of electronics. However, a solution to this problem emerged with the embedding of passive components within PCBs.

In recent years, PCB manufacturers have successfully integrated embedded resistors into circuit boards. This is achieved by incorporating special layers that are etched and buried within multilayer boards. Embedded resistors facilitate the transmission of discrete passives from the PCB surface to its internal layers, freeing up valuable space on the PCB surface for the placement of active components. This integration of embedded resistors not only aids in achieving compact designs but also enhances overall performance.

One notable advantage of embedded resistors is their ability to improve the reliability of circuit boards by eliminating the need for solder joints. Over time, solder joints can deteriorate, potentially compromising the reliability of the PCB. Additionally, embedded resistors offer benefits in signal routing. By eliminating the requirement for surface mount technology (SMT) vias, these resistors contribute to high-quality signal transfer across the circuit board. Moreover, embedded resistors provide superior performance compared to surface-mount device (SMD) resistors, particularly in terms of power supply.

By incorporating embedded resistors into PCB designs, manufacturers can enhance both the reliability and performance of electronic systems. These advancements in PCB technology support the ever-increasing demands of modern electronics, enabling more efficient and compact designs while ensuring robust and reliable operation.

How Selecting Resistor Components for the PCB?

When selecting resistors for PCBs, several factors need to be considered to ensure suitability for the intended application. Here are key considerations for choosing the right resistors:

Tolerance level:

The tolerance of resistors is an important parameter to evaluate. Resistors with tolerances of 0.1%, 5%, and 10% are commonly preferred. These tolerances enable easy integration into PCB designs without introducing significant complications. Some experts even recommend using resistors with a tolerance of 0.1% for projects that demand high precision. It’s worth noting that resistors with higher tolerances may be more cost-effective.

Power level:

The power handling capability of resistors is crucial for reliable performance. It is essential to choose resistors that can handle the expected power levels without overheating or causing damage to the PCB. Careful consideration should be given to the power rating of resistors when making purchasing decisions, ensuring they can withstand the specific requirements of the application.

Temperature:

Resistors have varying temperature ranges, and it is important to select resistors that can tolerate the anticipated temperatures in the PCB’s operating environment. For heat-sensitive applications and devices, resistors capable of withstanding high temperatures should be chosen. Evaluating the temperature range requirements of the application will help safeguard the PCB from heat-related damage and enhance its longevity.

Resistance:

The resistance value of resistors is a fundamental factor to consider. Resistors with a resistance of 1 kilo ohm are often considered suitable for enhancing PCB efficiency, performance, and durability. Before selecting resistors, it is crucial to verify their resistance value and ensure compatibility with the desired circuit specifications.

By carefully assessing these factors, you can make informed decisions when choosing resistors for your PCBs. Selecting resistors that align with the desired tolerance, power handling capability, temperature range, and resistance value will contribute to optimal performance and reliability of the PCB in its intended application.

Conclusion

In many scenarios, a standard 1% metal film resistor with a power rating of 0.125 watts is adequate for most applications. However, certain products necessitate a more comprehensive understanding of resistor specifications to ensure optimal performance. This is particularly true for applications involving power supply layouts, high-frequency layouts, audio work, and products operating in high ambient temperatures.

To achieve a design that prioritizes reliability and potentially avoid the need for time-consuming redesigns, it is crucial to carefully analyze the specifications and exercise caution when selecting the appropriate resistor. By taking these measures, one can ensure that the chosen resistor aligns with the specific demands of the application, thereby maximizing the overall design’s effectiveness.