Selecting the ideal drone controller board to fulfill all of your requirements can be a challenging undertaking due to the vast array of options available. Each controller board exhibits its own advantages and limitations, compounding the difficulty of choosing the right one.

Thanks to technological progress, drone controller boards have experienced significant advancements in the last decade. Manufacturers have integrated advanced micro-controllers capable of providing reliable and potent drone performance.

Compelling technological advancements have been made since the days of the KK2 boards. The prior KK2 controller board and its subsequent models were more substantial and had more processing ability compared to their contemporary counterparts — smaller in size yet equally potent.

Numerous factors must be considered when deciding on a drone controller board, therefore this guide aims to assist you in selecting the appropriate controller board that best suits your needs.

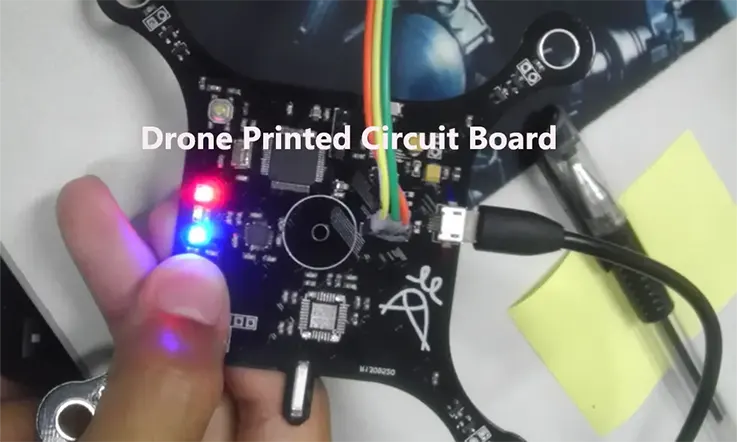

What is Drone PCB ?

A drone PCB refers to a specific type of printed circuit board used in drone technology primarily responsible for powering the different parts of the drone during operation. This circuit board has enabled engineers and drone manufacturers to create compact and precise connections between electrical components.

Previously, wires were the primary means of connecting various drone parts, but the use of copper and heavy solder joints in drone PCBs has significantly increased drone efficiency. There are several versatile types of drone PCBs, each with unique features and functions, particularly as voltage controllers on drone boards.

Drone PCBs distribute voltage throughout the circuit, providing clean power for excellent performance. They come in various sizes and layouts, making it easier for users to select the right size or design suitable for their drone.

Drone PCBs have a higher voltage and current capacity than other types of printed circuit boards, and they play a vital role in controlling the RPM of the motors in the input circuit. Overall, drone PCBs are essential components in achieving optimal drone functionality.

What are the Features of Drone PCB ?

A drone board is equipped with a suite of sensors that enable it to detect both the movements of the device itself as well as any commands received from the operator. Utilizing this information, the board is able to precisely modulate the speed and orientation of the drone’s propulsion systems to effect the desired motion. These capabilities represent the primary functions of a drone board.

● Firmware: The ability to install various firmware on drone boards provides a means to customize and optimize their functionality for specific tasks and applications. For example, iNav firmware is designed with GPS functionality in mind, while the KISS firmware is well suited for racing purposes. Further information about the diverse range of firmware options available for drone boards can be found in section four of this guide, which offers an in-depth examination of their features and capabilities.

● Processor: The drone board processor is commonly referred to as a microcontroller unit (MCU), which serves the important function of storing firmware code and performing complex calculations. Based on their respective processing power and memory capacity, five distinct types of drone board processors can be identified: F1, F3, F4, F7, and H7.

● UART: The acronym UART denotes Universal Asynchronous Receiver/Transmitter, which represents a hardware-based serial interface for enabling communication between a drone board and external components, such as Telemetry modules. While having multiple UART ports is beneficial, the presence of such ports on a drone board is contingent upon the board’s particular design and architecture.

● Layout: The layout of a drone board includes arrangements of solder pads which are a critical element in its design. While some may overlook their importance, boards with pads situated on the edges of the board typically deliver superior performance compared to those that feature all pads clustered in a single location.

● BlackBox: To facilitate the optimization and diagnostic assessment of your drone, the use of a BlackBox is essential.

Types of Drone PCB

Drone Power Production Board

A printed circuit board (PCB) referred to as a drone electric supply board (PDB), is an essential component responsible for distributing electricity to the different parts of a drone. In the past, drone sections were connected using wires that resulted in large weights due to the copper and solder connection points in the wire.

PDBs come in various forms, but many have similar features. Initially, PDBs were constructed using heavy copper PCBs. However, engineers have integrated voltage regulators into PDBs as the need for precise voltage management of various components developed, ensuring dependable and clean power distribution.

This is particularly critical when connecting video devices as they are vulnerable to electrical noise from motors and electronic speed controllers (ESCs). By minimizing noise and providing a stable voltage supply, PDBs enable video devices and other drone components to function optimally and contribute to the overall performance of the drone.

Drone Controller Board

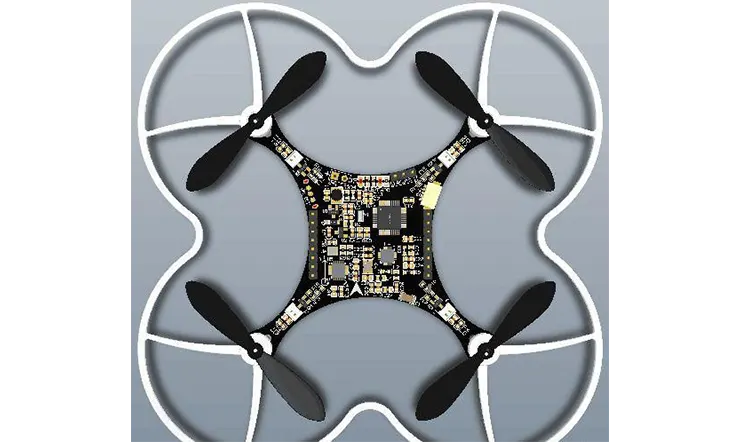

As previously mentioned, a drone controller board is a circuit board that comes in different sizes and controls the RPM of the motors in response to input signals. It procures user commands to fly and maintains the drone’s stability by controlling the speed of the motor.

The drone is commanded by a drone controller, which transmits instructions from a remote control. The flight controller board transmitters relay critical information, which the drone’s receiver receives.

Apart from the drone controller board, other types of drone circuit boards include tiny drone circuit boards, drone motherboards with remotes, and drone receiving boards with remotes, and the drone electrical distribution board or drone controlling board.

Each circuit board type provides unique functions that contribute to the overall drone function. By selecting the appropriate drone circuit board, users can ensure drone performance and maximize the drone’s capabilities for their specific needs.

Software for Drone PCB Controllers

● ArduPilot: ArduPilot is the latest and most advanced open-source flight controller software available for drones, offering a comprehensive range of features and unrivaled reliability. This software platform has the capability to manage a wide range of unmanned aerial vehicle (UAV) systems, including those utilized in helicopters, multi-rotors, aircraft, and even underwater naval vehicles like submarines. ArduPilot’s versatility and adaptability make it a highly sought-after software for drone enthusiasts who require a robust software platform capable of supporting a diverse range of applications and environments.

● PX4: Utilizing PX4 software for your drone offers a range of capabilities that have been lauded by experienced drone enthusiasts. It enables you to concentrate on enhancing your device without needing to engage in a complex development environment. This software platform provides a seamless and straightforward approach to optimizing your drone’s performance and functionality, freeing up your resources to focus on other areas of innovation and development.

● BetaFlight: BetaFlight is a popular drone control software utilized by both multi-rotor and fixed-wing drones, renowned for its cutting-edge features, high-performance capabilities, and top-notch customer support. It stands apart from other similar software platforms like Cleanflight and Baseflight due to its exceptional performance and innovative functionality. Moreover, BetaFlight is compatible with most drone controller circuit boards, and its utilization of the STM32F3 Processor is a feature that boosts its efficiency and practicality.

● LibrePilot: The LibrePilot software is a versatile program that facilitates the control and management of multi-copters and other unmanned aerial vehicles (UAVs). With a strong connection to the Open UAV project, the software platform strives to promote the advancement and evolution of both hardware and software technologies that are critical to industries such as robotics, drones, and automotive systems. Its overarching goal is to foster research, development, and innovation in these vital areas.

How to Program a Drone Flight Control Board ?

To program your drone flight control board, follow these simple steps:

● Connect Properly: Ensure that the receiver channels are appropriately linked to the corresponding channels.

● Software Installation: Download the preferred controller software and connect the controller to your laptop using a micro USB plug. Activate the power source of the receiver to enable connection with the transmitter.

● Drone Stabilization: Utilize the switches to program flight modes and other functions. Set the stabilisation mode breaker to either of the 3-way switches. Though you may also schedule in the transmitter menu, you can promptly verify the settings upon the transmitter screen.

● Keep it Level: Some programs enable users to visualize their drones’ alignment and distance and fine-tune them to ensure the optimal functioning of stabilization programming.

Materials Used to Make Drone PCB

A typical drone PCB is made up of several layers of materials that serve different functions. Here are some common materials used to make drone PCBs:

● Copper: used to create electrical conductivity between components and traces on the PCB.

● Substrate material: the base material upon which the electronic components are mounted. This can be made of different materials such as fiber glass epoxy (FR-4), polyimide, or ceramic materials.

● Solder Mask: a protective layer that is applied over copper traces to prevent oxidation, contamination and to insulate electrical conductivity.

● Silkscreen: a layer of white or colored ink used to label or identify different components or areas on the PCB.

● Gold or Silver Plating: used to improve electrical conductivity, to prevent corrosion or oxidation, or to enhance solderability.

● Adhesives: used to bond different layers of PCBs and components, typically an epoxy or acrylic based adhesive.

● Encapsulation or Coating: for components and the entire board, a protective layer such as conformal coating or potting is applied to provide environmental protection, insulation and to improve weather resistance.

These materials may vary depending on the type of drone PCB and specific design requirements.

Design Considerations for Drone PCB

Designing a PCB for a drone requires consideration of various factors to ensure optimal performance, reliability and safety. Here are some key PCB design considerations for drones:

● Size and shape: The size and shape of the PCB should be carefully designed to fit within the drone’s body and meet any other specific design requirements.

● Power Management: The PCB should be designed to effectively manage power consumption and distribution, to ensure stable and adequate power supply to all components on the board.

● Signal Integrity: Proper routing of signal traces on the PCB is essential to minimize interference and ensure signal integrity, especially for sensitive components such as sensors and control modules.

● Thermal Management: The PCB should be designed to dissipate heat effectively to prevent overheating and component damage.

● Weight: The PCB’s weight should be minimized to reduce the overall weight of the drone, which is critical for drone performance and flight time.

● Environmental Factors: The PCB should be designed to withstand environmental factors such as vibration, temperature, humidity, and potentially harsh weather.

● Electromagnetic Compatibility (EMC): EMC is important for avoiding interference with other electronics in the drone and achieving reliable operation.

● Testing and Validation: The final PCB design should be thoroughly tested and validated to ensure proper functionality, reliability, and safety before being integrated into the drone.

By taking these design considerations into account, designers can create effective and reliable PCBs for drones that meet specific design requirements.

Drone PCB Manufacturing Process

Here are the steps involved in drone printed circuit board (PCB) manufacturing:

Step 1: Cut and Prepare the Film

Cut a piece of film slightly larger than the circuit, as larger films are required for transparency. Avoid cutting to the same size as the circuit, allowing for more space to include the tape.

Step 2: Place the Cut Film onto the PCB

Put the cut film onto the PCB and use sticky tape to hold it down. Compress the space between the film and the PCB to avoid any air gaps.

Step 3: Mark the Solder Mask Points

Mark the areas where you do not need a solder mask, i.e., the points where you will solder the board. Since ultraviolet rays harden the paint, highlight where we will use solder. A permanent marker fails to block ultraviolet rays adequately. An alternative method is to design the paste points on the PCB and copy them to the cut board using an inkjet machine.

Step 4: Cut Another Film

After marking all the soldering points, remove the board and cut another film of identical measurements.

Step 5: Paste Solder

Apply some solder paste to the board using a stick. Place the cut film on top and attach it to the remaining frame board. Use a ruler to distribute the mask uniformly.

Step 6: Pair the Plugs Together

Put the labeled piece on the upper side and pair up all the plugs with those of the PCB.

Step 7: Dry in the Sun

Take it outdoors, where there are plenty of ultraviolet rays, and allow it to dry for roughly four to five minutes, depending on the depth of the paste. The deeper the paste, the longer it should be left to dry.

Step 8: Gently Remove Transparent Film

Gently remove the transparent film to avoid any damage.

Step 9: Clean the Surfaces

Clean the surfaces using a soft paper or cloth and alcohol to remove any dirt that may have accumulated.

Step 10: Scrape Off Hardened Solder Paste

Use a knife to scrape off any hardened solder paste.

Step 11: Apply Flux

Apply flux to the pad for a thorough cleaning. Please note that this step is not mandatory as soldering wires have undergone significant changes over time.

Step 12: Solder the Edge and Pads

Solder the edge and then use it on the pads.

Step 13: Buff with Sandpaper

Buff any rough edges with sandpaper, providing the mask with a lusterless look.

After completing these steps, the drone PCB is ready for use. Before use, solder all parts to prevent oxidation.

How to Choose the Best Drone Boards ?

Selecting the right drone controller board is crucial as it serves as the heart of the drone. To determine which drone flight controller board best suits your needs, consider the following points:

● Functionality: Consider the board’s functionality and ensure that it satisfies your requirements. Different drone controller boards offer a varying range of functionalities that cater to specific needs. Therefore, a thorough evaluation of your needs is necessary before choosing the right board.

● Level of Expertise: Consider your level of expertise in operating drones. If you are a beginner, choose a drone that is easy to operate and control. If you possess more advanced skills, you can explore drone controller boards with more extensive functionalities.

● Compatibility: Ensure that the flight controller board is compatible with the specific drone model or design you intend to build.

● Cost: Consider the cost of the drone board and determine whether it falls within your budget. While the cost should not be the sole determinant, it is essential to establish value for the money you spend.

● Reliability: Check product reviews and determine the drone board’s reliability in terms of performance, durability, and consistency in achieving your desired results.

Therefore, choosing the most appropriate drone board requires careful consideration of its functionality, level of expertise, compatibility with drone models, cost, and reliability, among other factors.

How Much a Drone Printed Circuit Board ?

The cost of a drone PCB can vary widely depending on factors such as size, complexity, quantity, and materials used. Generally, smaller and simpler PCBs cost less than larger and more complex ones.

Additionally, the cost of PCBs can decrease with larger production runs due to economies of scale, and higher quality materials and manufacturing techniques can also increase the overall cost.

As a rough estimate, a single drone PCB made using basic materials and manufacturing processes may cost anywhere from a few dollars to tens of dollars. However, the cost can increase significantly for more complex or specialized requirements.

Why Choose JarnisTech For Your Drone PCB ?

JarnisTech is a well-established drone printed circuit board (PCB) manufacturer, with a wealth of experience in the industry. We offer a diverse array of PCB prototypes, components, designs, layouts, and features that are backed by ISO, REACH, UL, and RoHS certifications, ensuring quality and safety.

Our team of highly skilled engineers and technical experts has over 20 years of experience, supporting the entire drone PCB manufacturing process. We provide unparalleled satisfaction to our clients through our products, which have earned us a reputation as a leading drone PCB manufacturer and supplier both locally and internationally.

At JarnisTech, we aim to provide our customers with practical solutions to all their drone PCB needs. With us, you can rest easy knowing that all your concerns and requirements will be met with the utmost professionalism and efficiency. Trust JarnisTech for all your drone PCB manufacturing needs.

Conclusion

Drone PCBs are an integral component in the operation and performance of drones. They are designed to be lightweight, durable, compact, and efficient, while effectively managing power and signal distribution. Recent advancements in materials, manufacturing processes, and testing of drone PCBs have resulted in the development of highly advanced drones, with increased capabilities.

If you plan to build a drone PCB or require PCBs that meet your unique needs, it is crucial to note that these boards form an essential part of the drone, which incorporates several other parts. In our earlier discussion on drone boards, we advocated the importance of understanding their features, the different types of drone circuit boards available, the software used to control drones, and how to select the most appropriate drone board.

For successful and safe flight operations, drone controller boards are a prerequisite for most UAVs. Therefore, selecting the best drone board for your specific purpose is critical in obtaining the desired results.

Related Posts:

1. Consumer PCB