As an electronic manufacturer, you may have encountered inquiries regarding the relevance of a 94v0 circuit board. This type of circuit board is sometimes compared to conventional PCBs, leading to questions about its advantages. These uncertainties usually arise from a lack of understanding of the 94v0 circuit board.

In demanding environments with fluctuating temperatures, engineers require a durable and reliable device that can endure prolonged use. As a result, circuit engineers have developed methods for evaluating and selecting suitable materials for PCB replication. With mounting interest in this area, it becomes essential to establish a framework for evaluating and testing different PCB design materials. This article offers a well-researched explanation of the 94v0 circuit board, shedding light on what it entails and its relevance to the electronic manufacturing industry.

What Is FR4 94v0?

FR4 94v0 is a type of circuit board material that has been tested and classified with a flame retardant rating of UL 94v0. The FR4 refers to the grade of the woven glass-reinforced epoxy resin that makes up the substrate, and the 94v0 rating indicates that the material meets certain fire safety standards, such as the ability to self-extinguish within 10 seconds after being exposed to a flame. This type of circuit board material is commonly used in various electronic applications, such as consumer electronics, industrial control equipment, and automotive electronics, where fire safety is an important consideratio

What Is a FR4 94v0 Circuit Board?

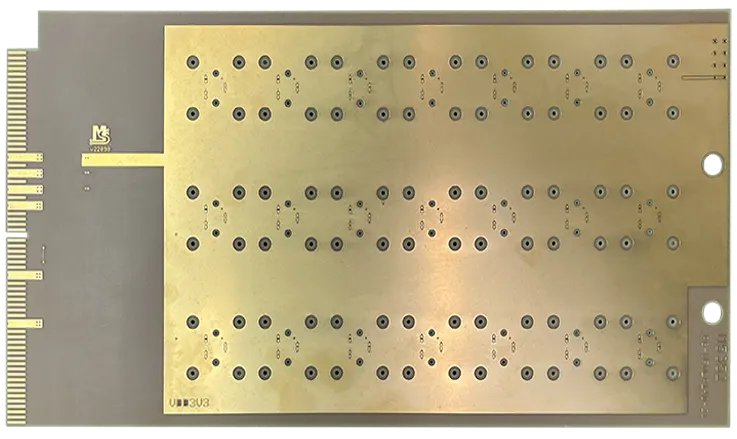

As engineer designers, it is vital to recognize the 94V-0 circuit board as a type of printed circuit board intended to provide highly dependable performance across diverse applications. This premium quality, reliable PCB is frequently utilized in many different electrical goods, and is generally made from conductive material, primarily copper, with insulation.

The 94V-0 rating is a UL flame resistance rating allocated to specific types of PCBs. This certification confirms that the board has been thoroughly tested and verified to be flame resistant up to 94 volts. As far as safety is concerned, this rating is of the utmost importance. This rating denotes that the 94V-0 circuit board can be safely employed in a range of environments, including those with high humidity and temperatures. Engineer designers must keep the 94V-0 rating in mind when selecting circuit board materials to guarantee that the circuit boards employed in their designs meet the prescribed safety standards

Classifications of FR4 94v0 Circuit Board

As a PCB manufacturer, it is essential to understand the UL 94 flammability test, which is a procedure that evaluates the flame resistance of material. The test requires using a specimen made from plastic, measuring 127 × 12.7 mm (5 x 0.5 in.) in size and meeting the minimum acceptable material thickness criteria.

To conduct the test, the specimen is exposed to a flame, and the resulting reaction is categorized according to six classifications by UL, each denoting varying degrees of flame resistance. PCB manufacturers must have an in-depth understanding of the UL 94 flammability test to ensure that the materials used in the manufacturing process meet the accepted standards for flame resistance, ultimately ensuring the safety and reliability of their products.

● V-0: The V-0 test is the most stringent test for PCBs in terms of flammability, conducted on a vertical scale with a burn time that should not exceed 10 seconds. This test does not allow any flammable drips to ensure safety.

● V-1: Similarly, the V-1 test is also conducted on a vertical scale, and the specimen must stop burning within 30 seconds without emitting any drips.

● V-2: The V-2 test is another vertical flame test, offering a 60-second burn time and allowing for minor flame dripping.

● 5VA: In the case of the 5VA test, the surface burning ends after 60 seconds, and the specimen should not ignite for more than 60 seconds even after five applications of the test flame. Neither the specimen nor the surface should have a burn-through hole, with the optimal specimen thickness for 5VA material being 2.5 mm.

● 5VB: With the 5VB test, the surface fire should be extinguished within approximately 60 seconds, and flame drips are not permitted under the test conditions. However, the specimen may suffer from burn-through or have holes forming on its surface.

● HB: Finally, the Horizontal Burn (HB) fire rating is the lowest of the UL 94 flammability criteria, requiring that a specimen with a thickness of 3 to 13 mm has a burn rate of less than 40 mm per minute. Moreover, the fire must extinguish before it reaches 100 mm of the test sample’s length.

A thorough understanding of the UL 94 classification system is necessary for PCB manufacturers to ensure the safety and reliability of their products.

Benefic of 94V-0 PCBs

As a reputable PCB manufacturer, we understand the technical aspects and unique advantages of using circuit board 94V-0 for various applications. The material used in the construction of this board has achieved a high rating in the UL 94V-0 flammability test, signifying that it is flame retardant, which is essential in ensuring safe operation in many electronic devices.

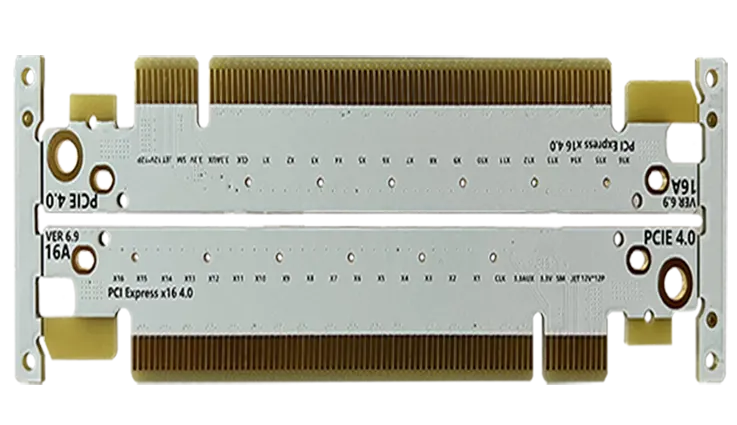

● Incorporating standardized connector pins into the design of the 94V-0 board simplifies component mounting and soldering during the assembly process. This streamlined design optimizes manufacturing efficiency and enables quicker turnaround times.

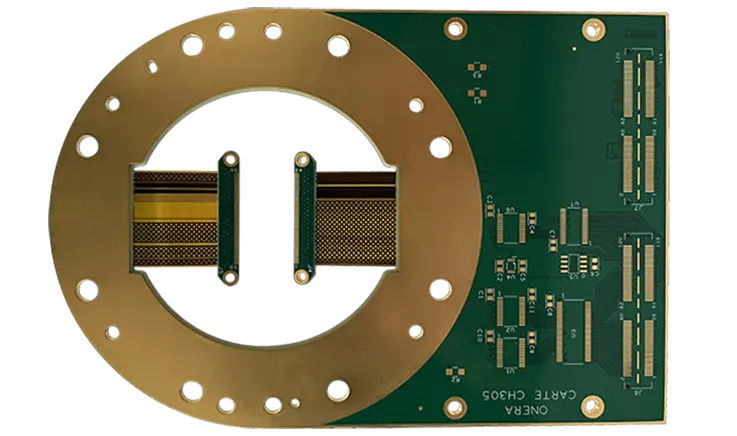

● The multi-layer structure of the 94V-0 circuit board is a recent advancement in PCB design that enhances assembly density by utilizing conductive copper lining and insulating materials. This innovative design allows for large circuit formations on small boards, ultimately reducing the board’s size and overall manufacturing costs.

● Another notable benefit of using 94V-0 rated circuit boards is their superior signal integrity capabilities. These high-quality boards prevent electromagnetic interference (EMI), ensuring a reliable signal transmission for improved device performance.

In a word, the excellent performance of the circuit board 94V-0 can be attributed to its flame retardant material, standardized connector pins, high assembly density, and signal integrity capabilities. As a PCB manufacturer, we highly recommend this board for electronic applications that require optimal performance and reliability.

How does the Electronics Industry Define 94v0 Circuit Boards

In the electronic industry, it is essential to have a clear understanding of the construction and functionalities of circuit board 94V-0. This high-quality PCB consists of a layer of conductive material, mainly copper, which is overlaid with insulation. The insulation restricts the flow of current and provides protection against potential damage. The board also contains an array of soldered components such as resistors, capacitors, and transistors, which are integral to building a functional circuit.

The circuit board 94V-0 has undergone stringent quality checks to ensure resilience to harsh weather conditions, making it resistant to moisture, temperature fluctuations, and shock. In addition, the board has been designed to withstand high voltages, up to 94 volts, permitting its use in a wide range of applications.

The circuit board 94V-0 surpasses several industrial standards and regulations, including being UL-listed and RoHS-compliant, indicating that it meets the essential requirements set for Restriction of Hazardous Substances. This board is also compliant with the European Union’s Low Voltage Directive.

In summary, circuit board 94V-0 presents an excellent alternative for electronic industry seeking a dependable, high-quality PCB. The board is engineered to deliver dependable performance, endure harsh environments, and comply with industrial regulations. Additionally, with its UL listing and RoHS-approved status, the board is suitable for an extensive range of applications, and its flame-resistant rating of up to 94 volts renders it appropriate for any application.

JarnisTech-the Best Manufacturer of 94v-0 Circuit Board

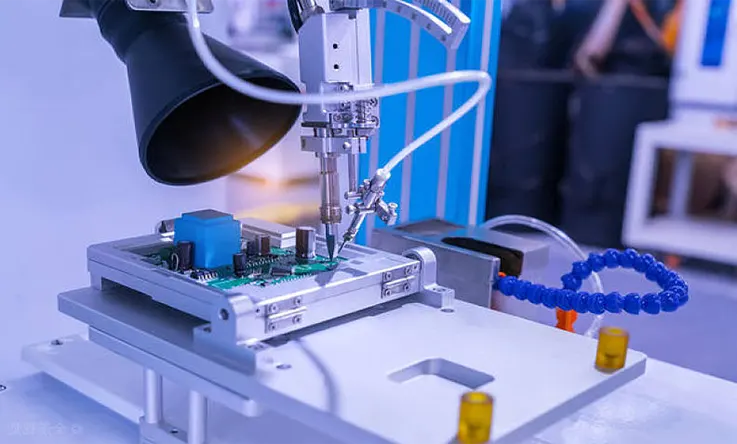

As a distinguished PCB manufacturer, JarnisTech has an impressive track record of over 20 years in producing, assembling, and testing printed circuit boards. We offer a broad range of services, including manufacturing UL 94V-0 rated PCBs and other types of PCBs. At JarnisTech, we prioritize delivering high-quality products, ensuring timely delivery, and providing exceptional customer service every step of the way.

Furthermore, we offer component procurement services through the Bill of Materials (BOM) and Surface Mount Technology (SMT) processes. Additionally, our Through-Hole Technology (THT) assembly method for circuit boards comes with rigorous testing to ensure the delivery of a PCB free of defects.

For a swift quotation on your UL 94V-0-rated printed circuit board, kindly click on this link to receive an immediate quote. Do not hesitate to contact us here for any queries or clarifications regarding our services. At JarnisTech, we ensure that our clients receive the best PCB manufacturing, assembly, and testing solutions for their electronics business needs.

How to Manufacture FR4 94v0 boards?

The process of manufacturing FR4 94v0 circuit boards typically involves the following steps:

● Preparing the base material: The manufacturing process starts with cutting a standard-sized FR4 sheet into smaller sizes. The sheets are then cleaned, and sometimes pre-baked to remove any moisture.

● Applying a copper layer: The cleaned and pre-baked FR4 sheet is then coated with a layer of copper using various techniques such as electroplating or lamination.

● Printing the circuit design: The next step involves printing the circuit design onto the copper layer using a process called photoengraving. This involves covering the copper layer with a photosensitive layer, curing the layer with UV radiation, and then exposing it to a light source to transfer the circuit design.

● Etching the circuit: Once the circuit design is printed, the sheet is etched with a chemical solution to remove the unwanted copper material, leaving only the desired circuit pattern.

● Drilling the necessary holes: The sheet is then drilled with small holes at specific locations (where components will be attached) using a high-speed drill or a laser.

● Applying soldermask and silkscreen layers: The board is then coated with a soldermask layer to protect the copper traces from oxidation and ensure that the solder adheres only to the desired areas. A silkscreen layer may also be applied to label the components and add logos or other information.

● Surface finish: The final step involves applying a surface finish to protect the board from environmental factors and improve its electrical conductivity. Common surface finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative).

After completing these manufacturing steps, the board is carefully inspected for defects and tested to ensure that it meets the required specifications before it is used in electronic device.

Advantages and Disadvantages of Using FR4 94v0 Boards

Advantages of Using FR4 94v0 Boards

● High level of thermal stability and low thermal expansion.

● Good electrical insulation properties and dielectric constant.

● Excellent mechanical strength, rigidity, and dimensional stability.

● Economical compared to other high-performance materials.

● Relatively easy to work with and can be fabricated using standard PCB manufacturing processes.

● High resistance to moisture, chemicals, and environmental factors.

● Good flame resistance properties.

Disadvantages of Using FR4 94v0 Boards

● Not suitable for high-frequency applications due to high losses.

● Relatively low thermal conductivity compared to metals and ceramics.

● May not be suitable for applications requiring high power handling capacity.

● Can be difficult to drill accurately due to its high hardness.

● Not suitable for applications that require low dielectric loss or stability in humid environments.

It’s worth noting that specific advantages and disadvantages may vary depending on the particular application, and careful consideration of the material’s properties is essential to ensure it’s the right choice for the application.

Applications of FR4 94v0 Circuit Board

It is crucial to recognize the diverse applications of circuit board 94V-0 in various industries. This high-quality board is widely utilized in consumer electronics, industrial machinery, aerospace, and medical equipment. Its versatility and reliability make it a popular choice in these industries.

Circuit board 94V-0 can be used to construct intricate circuits while also providing dependable performance in different operational environments. The board’s flame retardant material and high assembly density make it a suitable option for applications that demand high performance.

In addition, circuit board 94V-0’s broad range of use cases across various industries underscores its exceptional quality and design. As PCB design engineers, it is essential to consider the potential advantages of using 94V-0 rated circuit boards when selecting a PCB for specific applications.

What are the Most Compatible PCB Substrates with 94V-0?

In the realm of printed circuit boards (PCBs), the substrate is a vital component that is utilized to separate the two copper layers. It is responsible for providing the necessary support to the entire structure of the bare PCB. PCB substrates can be made of a single material, such as ceramic, or a composite material, which is a combination of multiple materials to create a premium-quality substance with excellent physical, chemical, mechanical, and environmental characteristics. Materials like FR-4 and Ceramic are two such examples of PCB substrates that are highly suitable for meeting the UL 94V-0 test requirements. These materials possess exceptional fire-resistant properties and are ideal for use in electronic applications where safety is of utmost importance.

● FR-4: FR-4 is a composite material composed of fiberglass, either woven or non-woven, that is impregnated with an epoxy resin. This particular substrate material is the most widely used in the realm of printed circuit boards (PCBs). Moreover, FR-4 is a fire-retardant material, which means that it has the ability to resist the spread of fire.

● Ceramic: Ceramics serve as another exemplar of a fire-resistant substance that has inherent properties which prevent ignition. Additionally, ceramics possess several notable attributes, such as strong mechanical strength, a smaller loss tangent, and a higher dielectric constant that remains stable. However, the drawback of ceramics is their susceptibility to crack when exposed to elevated temperatures.

Comparison of FR4 94v0 with Other Circuit Board Materials

Here is a comparison of FR4 94v0 circuit board material with other circuit board materials:

● Cost: FR4 94v0 circuit boards are relatively inexpensive compared to some high-performance materials that can be more expensive.

● Thermal Conductivity: FR4 94v0 circuit boards have relatively low thermal conductivity, which can limit their heat management capabilities. Materials with high thermal conductivity, such as metal and ceramic, offer better thermal management.

● Dielectric Constant: FR4 94v0 circuit boards have a dielectric constant of 4.4, which is similar to commonly used materials such as polyimide (PI) and polytetrafluoroethylene (PTFE), but lower than materials such as polyimide film and zirconia.

● Moisture Absorption: FR4 94v0 circuit boards have a relatively high moisture absorption rate, which makes them susceptible to environmental humidity and other factors.

● Mechanical Strength: FR4 94v0 circuit boards have good mechanical strength and rigidity, but they are more brittle compared to metal materials.

● Flame resistance: FR4 94v0 circuit boards are classified with a flame retardant rating of UL 94v0, which prevents the flame from spreading during a fire. Other materials may have different flame retardant ratings.

● Manufacturing Difficulty and Ease of Use: FR4 94v0 materials are relatively easy to manufacture and use, and they can also be efficiently machined into other materials. The manufacturing and machining processes for other high-end materials can be more complicated.

● Resistance to Chemicals and Environmental Factors: FR4 94v0 circuit boards have high corrosion and chemical resistance and environmental stability but cannot withstand extreme environmental and chemical exposure.

● Electrical Conductivity and Reliability: FR4 94v0 circuit boards offer good electrical performance and high reliability. Some high-performance materials offer better electrical characteristics and reliability but typically require higher handling and usage demands.

● Availability and Applicability to Specific Uses: FR4 94v0 circuit boards are widely used and available for a variety of applications (such as consumer electronics, military, medical, etc.). Other materials may be specific to certain applications and harder to obtain.

Note that this is a general comparison, and specific comparisons and considerations may vary depending on the application.

Why Do You Need 94V-0 Circuit Board?

This factor can be seen in three ways:

1. From the Manufacturer’s Perspective

In the realm of manufacturing, maintaining brand reputation is crucial, as producing substandard electrical equipment can lead to negative reviews and diminished sales. While cost-effectiveness may be a significant factor for certain electronic products, some high-demand applications require the use of 94V-0 printed circuit boards to achieve optimal quality. Investing in higher quality PCB boards can yield several benefits, such as enhanced brand recognition, greater ratings, increased credibility, and improved profitability. Manufacturers might consider raising product pricing to reflect the added value of superior hardware.

Alternatively, manufacturers may choose to implement a grading system, wherein devices featuring 94V-0 circuit boards receive a higher grade compared to those with conventional PCBs. This enables customers to choose whether they prioritize price or quality factors. Adopting this flexible pricing model permits manufacturers to charge competitive prices for low-quality gadgets, while premium pricing may be assigned to high-quality items.

2. From the Perspective of an Electronic Developer

For independent electronics developers, building long-lasting electrical equipment can boost their chances of securing new project opportunities and recommendations, similar to manufacturers. Integrating high-quality electrical circuit boards in one’s project is one effective method to achieve exceptional product performance and surpass customers’ expectations.

In academic settings, electrical engineering students must demonstrate proficiency by crafting dependable electrical circuits in their school projects to attain high grades. The devices should be capable of withstanding adverse conditions and endure rigorous testing without any failure to showcase the students’ engineering abilities.

3. From the Consumer’s Perspective

As a discerning customer, you face the decision of either purchasing low-priced electrical equipment at the cost of compromising quality or investing in high-quality equipment that may entail higher costs but promises longevity.

Unbranded electronic equipment is typically fitted with low-grade PCB circuit boards that may lack fire retardant properties. Conversely, branded and genuine grade products are more likely to feature advanced circuit boards that have been tested to withstand intense heat. This approach not only ensures safety but also provides an enhanced level of functionality and reliability.

It is worth considering that manufacturers are also striving to establish their reputation and brand image by delivering high-quality electrical products. As a result, many products in the market offer superior performance and durability.

Know More on the 94v0 Circuit Board

In the production of printed circuit boards (PCBs), the 94v0 circuit board diagram serves as a useful tool to provide a visual representation of the board’s components. These diagrams are conveniently available online, providing easy access and reference.

To ensure safety and satisfy standard device fire prevention regulations, the 94v0 PCB undergoes a series of rigorous fire tests after production.

Furthermore, the material used for a PCB, such as Fr4 94v0, is a crucial determinant that demonstrates the manufacturer’s commitment to producing high-quality boards. This selection reflects the need for PCBs that are both resilient and capable of high-performance output, highlighting the manufacturer’s dedication to delivering superior electronic products.

Summary

In summary, the 94V-0 PCB circuit board is a crucial component that offers durability and reliability, enabling electrical equipment to withstand high heat levels in even the toughest working environments. Additionally, the UL94V-0 inflammability test guarantees optimal performance and safety standards.

As a leading PCB manufacturer, we offer comprehensive PCB assembly services and are capable of creating custom 94v-0 circuit boards tailored to your project’s specific requirements.

For more details regarding our high-quality PCB design and assembly services, please feel free to contact us. We guarantee the most competitive price in the market.