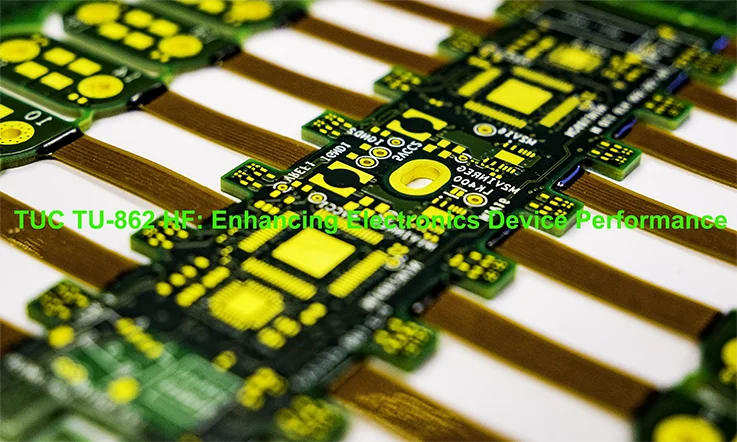

In today’s rapidly evolving electronics industry, manufacturers are constantly seeking high-performance materials that can meet the increasing demands of modern electronic devices. TUC TU-862 HF emerges as a cutting-edge solution, offering a wide range of features and capabilities that empower electronic manufacturers to achieve superior results. This article serves as a comprehensive overview of the TUC TU-862 HF PCB materials, highlighting their key attributes and benefits from the perspective of electronic manufacturers.

Overview of TUC TU-862 HF

TU-862 HF is high-performance, halogen-free materials specifically designed for use in printed circuit boards (PCBs). Unlike traditional FR-4 materials that utilize brominated resin for flame retardancy, TU-862 HF achieve a flammability class of UL94V-0 by incorporating phosphorous and nitrogen compounds into the materials. This innovative approach ensures compliance with stringent safety standards while eliminating the use of halogenated resins, thereby addressing environmental concerns.

The composition of TU-862 HF includes epoxy resin and E-glass fabric, resulting in a robust and reliable substrate for PCBs. These materials have been carefully engineered to offer exceptional performance and numerous advantages. They are compatible with the automated optical inspection (AOI) process, facilitating efficient quality control during production. Additionally, they exhibit UV-blocking characteristics, providing enhanced protection against harmful ultraviolet radiation.

TU-86P HF is specifically designed to be used in conjunction with TU-862 HF for the fabrication of multilayer printed wire boards, while TU-862 HF is suitable for single or double-sided applications as well. Both variants of this green material series offer outstanding thermal stability, making them ideal for applications that involve severe thermal cycles or extensive assembly work. Furthermore, they demonstrate superior chemical resistance and resistance to Conductive Anodic Filamentation (CAF), ensuring long-term reliability in challenging environments.

The use of TU-862 HF laminates not only ensures compliance with safety standards but also contributes to environmental sustainability by eliminating the potential hazardous effects associated with halogenated resins. These materials are particularly well-suited for applications that require high thermal performance, resistance to lead-free soldering assembly, and demanding chemical environments.

Performance and Processing Advantages

TUC TU-862 HF PCB materials offer several performance and processing advantages that make them a preferred choice in the industry.

Low halogen and Lead free process compatibles:

TUC TU-862 HF PCB materials includes low halogen and environmentally friendly options that meet stringent regulatory requirements. These materials are designed to be compatible with lead-free processes, ensuring compliance with industry standards and environmental regulations.

Compatible to PCB processes:

Furthermore, these materials are specifically formulated to be compatible with various PCB processes, allowing for seamless integration into manufacturing workflows. They exhibit excellent processability and can be easily incorporated into standard PCB fabrication processes.

Very low coefficient of thermal expansion:

One of the key advantages of these materials is their very low coefficient of thermal expansion (CTE). This characteristic ensures dimensional stability and minimizes the risk of failure due to thermal stress, particularly in applications with significant temperature variations.

Moisture resistance:

Moisture resistance is another notable feature of these materials. They have been engineered to withstand exposure to moisture and humidity, offering enhanced reliability and longevity in challenging environments.

Anti-CAF capability:

In addition, these materials possess anti-Conductive Anodic Filamentation (CAF) capability, which is crucial for applications where electrical conductivity needs to be maintained over extended periods. This capability ensures the long-term reliability and performance of the PCBs in demanding operating conditions.

Higher Tg characteristics:

Lastly, these materials exhibit higher glass transition temperature (Tg) characteristics, indicating improved thermal stability and resistance to elevated temperatures. This attribute is particularly important in applications that involve high operating temperatures or thermal cycling.

Application of TUC TU-862 HF

The TUC TU-862 HF PCB materials are commonly used in the electronics industry for various applications. Some of the key applications include:

Backpanel, High performance computing:

These high-performance PCB materials, TU-862 HF, find extensive application in various sectors, including backpanels, high-performance computing, line cards, storage, servers, telecom, base stations, and office routers. Their exceptional properties make them suitable for demanding electronic systems in these industries.

In backpanel applications, where high-speed data transmission and signal integrity are critical, TU-862 HF provide reliable performance and excellent thermal stability. These materials ensure the integrity of high-speed signals and enable efficient data transfer in backplane architectures.

Line cards, Storage:

In the realm of high-performance computing, these materials offer the necessary reliability and thermal resistance to withstand the demanding requirements of advanced computing systems. They provide a stable platform for the intricate interconnections and high-speed data transfer within the computing infrastructure.

For line cards and storage applications, TU-862 HF deliver exceptional performance and durability. These materials enable efficient signal transmission, ensuring reliable data storage and retrieval processes. They offer superior chemical resistance and withstand the challenges posed by harsh operating conditions.

Servers, Telecom, Base station:

In the realm of servers, telecom, and base stations, these materials play a crucial role in maintaining the integrity of electronic systems. They provide the necessary thermal stability to withstand the heat generated by these systems and ensure reliable signal transmission for seamless communication.

Office Routers:

Even in office routers, where reliability and performance are essential, TU-862 HF and TU-86P HF materials excel. They offer excellent thermal stability for sustained operation and enable efficient data transfer to support reliable network connectivity.

Industry Approvals of TUC TU-862 HF

TUC TU-862 HF PCB materials have received various industry approvals and certifications, indicating their compliance with industry standards and requirements. Some of the notable industry approvals for TUC TU-862 HF include:

IPC-4101E Type Designation: The TU-862 HF materials are classified under IPC-4101E standards, specifically designated as /127, /128, and /130. This classification ensures that the materials meet the required specifications and performance criteria for their respective types.

IPC-4101E/130 Validation Services QPL Certified: The TU-862 HF materials have undergone rigorous validation services and have been certified by the Qualified Products List (QPL) under IPC-4101E/130. This certification validates their compliance with industry standards and confirms their reliability and performance.

UL Designation – ANSI Grade: The TU-862 HF materials have received a UL (Underwriters Laboratories) Designation, specifically categorized as FR-4.1 according to ANSI (American National Standards Institute) grading. This designation signifies that the materials meet the stringent flammability and electrical performance requirements set by UL and ANSI.

UL File Number: The TU-862 HF materials are associated with a UL File Number, specifically identified as E189572. This file number serves as a reference for the materials’ compliance with UL standards and provides traceability and verification of their safety and reliability.

Flammability Rating: The TU-862 HF materials have achieved a flammability rating of 94V-0. This rating indicates that the materials have undergone rigorous testing and have demonstrated excellent resistance to ignition and flame propagation, ensuring their safety and reliability in applications where fire resistance is critical.

Maximum Operating Temperature: The TU-862 HF materials have a maximum operating temperature of 130°C. This characteristic highlights their ability to withstand elevated temperatures without compromising their mechanical or electrical properties. It ensures the materials’ suitability for applications that involve high-temperature environments or thermal stress.

Standard Availability of Tu-862 HF

The TUC TU-862 HF PCB materials offer a range of options in terms of thickness, copper foil cladding, prepregs, and glass styles, providing versatility and flexibility for various application requirements:

Thickness: The materials are available in a thickness range of 0.002″ [0.05mm] to 0.062″ [1.58mm]. This wide thickness range allows for customization and ensures compatibility with different design specifications. The materials can be obtained in sheet or panel form, providing convenience and adaptability to manufacturing processes.

Copper Foil Cladding: The TU-862 HF materials feature copper foil cladding options ranging from 1/3 oz to 5 oz (HTE) for built-up and double-sided PCBs, as well as H oz to 2 oz (MLS) for other applications. This variety of copper foil weights caters to diverse electrical conductivity and current-carrying requirements, enabling the materials to be used in a wide range of electronic designs.

Prepregs: The materials offer prepregs, which are available in both roll and panel form. Prepregs are resin-impregnated fiberglass sheets used in PCB fabrication. The availability of prepregs in different forms provides flexibility in the manufacturing process, allowing for efficient and precise application of resin during lamination.

Glass Styles: The TU-862 HF materials are compatible with various glass styles, including 106, 1080, 2113, 2116, 1506, 7628, and more. These different glass styles refer to specific fabric weave patterns and weights used in the construction of the PCB laminate. The availability of multiple glass styles allows designers to select the most suitable option based on mechanical strength, dimensional stability, and other performance requirements.

Conclusion

The TUC TU-862 HF PCB materials present electronic manufacturers with a compelling solution to enhance their manufacturing processes and meet the evolving demands of the electronics industry. With exceptional performance characteristics, compliance with industry standards, and a wide range of options in thickness, copper foil cladding, prepregs, and glass styles, these materials offer versatility, reliability, and efficiency.

By incorporating TUC TU-862 HF materials into their manufacturing workflows, electronic manufacturers can achieve superior results, ensuring the production of high-quality, high-performance electronic devices. Embracing the advanced capabilities of TUC TU-862 HF materials is a strategic choice for manufacturers seeking to stay ahead in the competitive landscape of electronic manufacturing.

Our services

TUC PCB Laminate & Materials Series