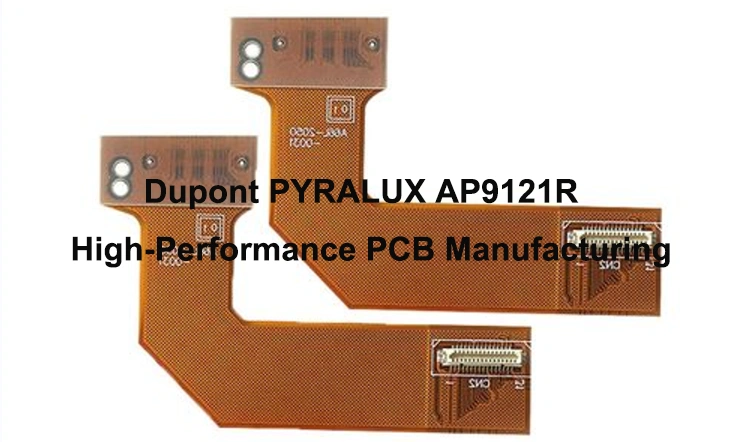

In the rapidly evolving realm of PCB manufacturing, the selection of appropriate materials holds paramount importance for achieving optimal performance and reliability. Within the vast array of options available, Dupont PYRALUX AP9121R emerges as a versatile and high-performance solution. Boasting a unique amalgamation of flexibility, thermal efficiency, electrical properties, and mechanical robustness, PYRALUX AP9121R presents PCB manufacturers with an exceptional material that effectively satisfies the exacting demands of modern electronic applications.

This article provides an in-depth exploration of the key features and advantages offered by Dupont PYRALUX AP9121R, elucidating its position as a preferred choice for cutting-edge PCB manufacturing.

What is Dupont PYRALUX AP9121R?

Dupont Pyralux AP9121R is a type of flexible printed circuit board (PCB) laminate material developed by Dupont, a leading materials science company. Pyralux is a brand name for Dupont’s line of flexible circuit materials.

AP9121R is a specific grade of Pyralux laminate designed for high-performance applications. It combines a polyimide film with a copper foil layer, providing excellent electrical and mechanical properties. The polyimide film acts as the substrate for the circuit, while the copper layer serves as the conductive pathway.

Benefits of Dupont Pyralux AP9121R PCB Laminates

The key features and benefits of Dupont Pyralux AP9121R PCB laminates include:

1. Flexibility: The material offers flexibility, allowing it to conform to various shapes and contours. This makes it suitable for applications where traditional rigid PCBs cannot be used.

2. High Temperature Resistance: Pyralux AP9121R can withstand high temperatures, making it suitable for applications that require exposure to elevated temperatures during operation or manufacturing processes.

3. Excellent Electrical Properties: The material offers good electrical insulation properties, allowing it to handle high-frequency signals and high-power applications.

4. Dimensional Stability: Pyralux AP9121R exhibits excellent dimensional stability, ensuring that the circuit maintains its shape and electrical performance even under stress or varying environmental conditions.

5. Reliability: The material is designed to provide reliable performance, ensuring the longevity and durability of the circuits it is used in.

6. Compatibility: Pyralux AP9121R can be used with various fabrication and assembly processes, including traditional PCB manufacturing techniques.

Overall, Dupont Pyralux AP9121R PCB laminates are well-suited for applications that require flexible circuits with high-performance characteristics, such as aerospace, automotive, medical devices, consumer electronics, and other industries where space constraints or unique form factors are a consideration.

Manufacturing Process of Pyralux AP9121R

The manufacturing process of Pyralux AP9121R involves several steps. Here is a general overview of the process:

1. Material Preparation:

Pyralux AP9121R is a composite material consisting of a flexible polyimide film and copper foil.

The polyimide film is typically supplied in rolls and needs to be inspected for any defects or imperfections.

Copper foil is also supplied in rolls and may undergo surface treatment to enhance adhesion.

2. Lamination:

In this step, the copper foil is laminated onto the polyimide film to create the base material for Pyralux AP9121R.

The lamination process involves applying heat and pressure to bond the copper foil and polyimide film together.

The resulting material has a uniform copper layer on one or both sides of the polyimide film.

3. Imaging:

The laminated material is then coated with a photosensitive layer known as a dry film resist.

A photomask, which contains the desired circuit pattern, is aligned and placed over the dry film resist.

The material is exposed to UV light, which transfers the circuit pattern onto the dry film resist.

4. Etching:

After imaging, the material undergoes a chemical etching process to remove the unwanted copper.

The dry film resist acts as a protective layer, ensuring that only the desired circuit pattern remains.

The etching process is typically performed using an etchant solution that selectively dissolves the exposed copper.

5. Drilling:

Holes for component mounting and interconnections are drilled into the Pyralux AP9121R material.

Precision drilling machines are used to create holes of specific diameters and locations.

The drilled holes are typically plated with a conductive material to establish electrical connections.

6. Surface Finishing:

The surface of the Pyralux AP9121R material may undergo surface finishing processes, such as copper plating or solder mask application.

Copper plating helps improve the solderability and conductivity of the circuitry.

Solder mask application involves applying a protective layer over the circuitry to prevent short circuits and provide insulation.

7. Testing and Inspection:

The manufactured Pyralux AP9121R PCBs undergo various tests and inspections to ensure their quality and functionality.

Electrical tests, such as continuity checks and impedance measurements, are performed to verify the circuitry.

Visual inspections are conducted to identify any defects or abnormalities in the PCBs.

8. Final Processing:

Once the PCBs pass all the required tests and inspections, they are subjected to final processing steps.

This may include cutting the PCBs into individual boards, edge profiling, and any additional assembly processes required for the specific application.

It’s important to note that the manufacturing process can vary depending on the specific requirements and manufacturing capabilities of the PCB manufacturer. The above steps provide a general overview of the typical manufacturing process for Pyralux AP9121R.

Pyralux AP9121R Applications in Aerospace

In the aerospace industry, Dupont Pyralux AP9121R PCB laminates can be utilized in various applications where flexible circuits are required. Some specific applications where Pyralux AP9121R is commonly used in the aerospace industry include:

Avionics Systems:

Avionics encompass various electronic systems used in aircraft, including communication, navigation, flight control, and monitoring systems. Pyralux AP9121R can be employed in flexible circuitry for avionics applications, providing reliable signal transmission and interconnection.

In-flight Entertainment Systems:

Flexible circuits made with Pyralux AP9121R can be used in in-flight entertainment systems, allowing for flexible and lightweight interconnections between displays, control panels, and other components.

Sensors and Instrumentation:

Aerospace applications often involve the use of sensors and instrumentation for monitoring and data collection. Pyralux AP9121R can be used to create flexible circuits for sensor interconnects, providing reliable signal transmission and flexibility in sensor placement.

Satellites and Spacecraft:

In satellite and spacecraft applications, where weight and space constraints are critical, Pyralux AP9121R can be used to create lightweight and flexible circuits. These circuits can be used for various purposes, such as interconnecting electronic components, power distribution, and payload systems.

Unmanned Aerial Vehicles (UAVs):

Pyralux AP9121R can be employed in the construction of flexible circuits for UAVs, enabling lightweight and flexible interconnections between different subsystems, such as flight control, communication, and payload systems.

Lighting Systems:

The aerospace industry utilizes various lighting systems, including cockpit lighting, cabin lighting, and external lighting. Pyralux AP9121R can be used in flexible circuits for these lighting systems, providing efficient and reliable electrical connections.

It’s important to note that the specific applications of Pyralux AP9121R may vary depending on the requirements and specifications of each aerospace project.

Comparing Pyralux AP9121R: Flexibility and Reliability

Pyralux AP9121R exhibits excellent flexibility compared to many other PCB laminates, making it a popular choice for applications that require flexible circuits. The polyimide film used in Pyralux AP9121R provides exceptional flexibility, allowing the circuit to conform to various shapes and contours. This flexibility is particularly advantageous in industries such as aerospace, automotive, and consumer electronics, where space constraints or unique form factors are common.

In terms of reliability, Pyralux AP9121R is designed to offer robust performance. It possesses good dimensional stability, meaning it maintains its shape and electrical performance even under stress or varying environmental conditions. This reliability is crucial for maintaining the integrity of the circuit and ensuring its long-term functionality.

Compared to rigid PCB laminates, Pyralux AP9121R may have slightly lower reliability due to its flexible nature. Flex circuits generally experience more mechanical stress and strain during operation or handling, which can potentially affect their reliability. However, Pyralux AP9121R is engineered to minimize these risks and provide reliable performance in the intended application environments.

It’s worth noting that the choice of PCB laminate depends on the specific requirements of the application. While Pyralux AP9121R offers excellent flexibility and reliability, there may be other laminates available in the market that could better suit certain specialized applications. It’s always recommended to consult with the manufacturer or supplier to determine the most suitable laminate for a specific project, taking into account factors such as operating conditions, mechanical stress, signal integrity requirements, and environmental considerations.

Pyralux AP9121R Comparison with Other PCB Materials

When comparing Dupont Pyralux AP9121R with other PCB materials, several factors can be considered. Here are some points that could be discussed in a comparison:

1. Flexibility and Bendability:

Pyralux AP9121R is a flexible PCB material designed for applications that require flexibility and bendability.

Compared to rigid materials like FR-4, Pyralux AP9121R offers greater flexibility, allowing it to conform to curved surfaces or fit into tight spaces.

2. Thermal Performance:

Pyralux AP9121R exhibits good thermal performance, making it suitable for applications that involve heat dissipation.

Compared to some other flexible PCB materials, Pyralux AP9121R may offer better thermal conductivity and improved heat resistance.

3. Electrical Performance:

Pyralux AP9121R has good electrical properties, including low dielectric constant and loss tangent, which contribute to signal integrity and reduced signal loss.

When compared to other flexible PCB materials, Pyralux AP9121R may provide better electrical performance in terms of impedance control and signal transmission.

4. Mechanical Strength:

Pyralux AP9121R offers good mechanical strength and durability, allowing it to withstand bending and flexing without compromising performance.

When compared to some other flexible PCB materials, Pyralux AP9121R may have higher tensile strength and better resistance to mechanical stress.

5. Chemical Resistance:

Pyralux AP9121R exhibits good resistance to various chemicals, including solvents and cleaning agents commonly used in PCB manufacturing processes.

Compared to certain other flexible PCB materials, Pyralux AP9121R may provide better chemical resistance, ensuring long-term reliability in harsh environments.

6. Cost and Availability:

The cost and availability of Pyralux AP9121R may vary depending on the region and specific requirements.

When comparing with other PCB materials, factors such as material cost, manufacturing processes, and market availability should be considered.

It’s important to note that the comparison may vary depending on the specific materials being compared and the requirements of the application. Conducting thorough research and consulting with industry experts or manufacturers can provide more detailed and accurate insights for specific comparisons.

In Conclusion

Dupont PYRALUX AP9121R is a game-changer in the realm of PCB manufacturing. Its exceptional flexibility, thermal performance, electrical properties, and mechanical strength make it an ideal choice for a wide range of applications. PCB manufacturers can rely on PYRALUX AP9121R to deliver high-performance, reliable, and durable PCBs that meet the stringent demands of modern electronic devices.

As technology continues to evolve, Dupont PYRALUX AP9121R remains at the forefront, enabling innovative designs and pushing the boundaries of what is possible in the world of PCB manufacturing. Embracing PYRALUX AP9121R is a testament to a commitment to excellence and delivering top-notch PCB solutions to the market. With its exceptional properties and versatility, PYRALUX AP9121R is poised to shape the future of high-performance PCB manufacturing.

Our services

Dupont PCB Laminates & Materials