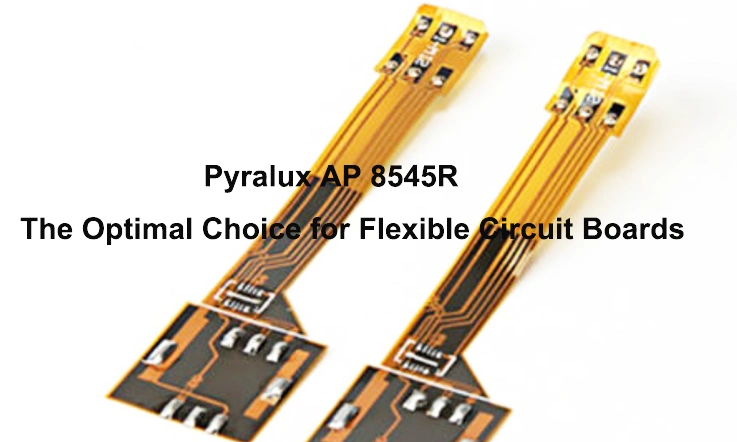

Welcome to our article, where we delve into the exceptional properties of DuPont Pyralux AP 8545R, a remarkable flexible circuit board material. As circuit board manufacturers, we understand the critical importance of selecting the right material for ensuring reliability and performance. Pyralux AP 8545R has emerged as the preferred choice among manufacturers for flexible circuit board applications, thanks to its outstanding characteristics and numerous advantages.

Overview of DuPont Pyralux AP 8545R

DuPont Pyralux AP 8545R is an advanced and high-performance flexible circuit material offered by DuPont, a leading manufacturer in the field of electronic materials. This material is specifically designed for applications that demand exceptional thermal, electrical, and mechanical properties in a flexible format.

Pyralux AP 8545R is a composite material consisting of a polyimide film substrate and a proprietary acrylic adhesive system. The combination of these components results in a flexible laminate that offers excellent performance and reliability in various electronic applications.

Properties and Features of DuPont Pyralux AP 8545R

One of the key features of DuPont Pyralux AP 8545R is its exceptional thermal stability. It can withstand high temperatures, making it suitable for applications that involve elevated operating conditions. The material exhibits low thermal expansion, ensuring reliable performance even in extreme temperature environments.

In terms of electrical properties, Pyralux AP 8545R provides excellent dielectric strength and insulation properties. It offers low dissipation factor and high breakdown voltage, enabling efficient signal transmission and minimizing signal loss in electronic circuits. Additionally, the material exhibits good dimensional stability, ensuring consistent electrical performance over time.

Mechanically, Pyralux AP 8545R offers outstanding flexibility, allowing it to conform to complex shapes and contours. It can be bent, folded, or flexed without compromising its electrical or mechanical integrity. This flexibility opens up opportunities for design innovation and miniaturization in various industries, including aerospace, consumer electronics, medical devices, and automotive applications.

DuPont Pyralux AP 8545R is manufactured with stringent quality control processes to ensure consistent performance and reliability. It undergoes rigorous testing and certification to meet industry standards and customer requirements.

Overall, Pyralux AP 8545R is a versatile and high-quality flexible circuit material that combines thermal stability, excellent electrical properties, and mechanical flexibility. Its unique attributes make it an ideal choice for demanding applications where reliability, performance, and design flexibility are paramount.

Advantages and Benefits Using Pyralux AP 8545R

Using DuPont Pyralux AP 8545R in electronic applications offers several advantages and benefits, making it a preferred choice for many manufacturers. Here are some key advantages and benefits of using this advanced flexible circuit material:

Enhanced Reliability and Durability:

Pyralux AP 8545R is engineered to provide exceptional reliability and durability in demanding environments. Its robust construction and high-quality materials ensure consistent performance even under harsh conditions, such as high temperatures, humidity, and mechanical stress. This reliability translates into improved product longevity and reduced failure rates.

Improved Signal Integrity and Electrical Performance:

The excellent electrical properties of Pyralux AP 8545R contribute to enhanced signal integrity and performance in electronic circuits. It offers low dielectric loss and high breakdown voltage, minimizing signal attenuation and ensuring efficient signal transmission. This leads to improved overall system performance and reduced signal distortion.

Design Flexibility and Miniaturization Opportunities:

With its exceptional flexibility, Pyralux AP 8545R opens up new possibilities for design flexibility and miniaturization. The material can be easily bent, folded, or flexed to conform to complex shapes and contours, allowing for compact and space-saving designs. This flexibility enables the creation of innovative and lightweight electronic devices, making it particularly valuable in industries such as aerospace, consumer electronics, and medical devices.

Compatibility with High-Temperature Environments:

Pyralux AP 8545R exhibits excellent thermal stability and can withstand high temperatures, making it suitable for applications that operate in elevated temperature environments. The material maintains its structural integrity and electrical performance even under extreme thermal conditions, ensuring reliable operation over an extended period.

Ease of Processing and Manufacturing:

DuPont Pyralux AP 8545R is designed to be easily processed during manufacturing. It can be laminated, etched, plated, and assembled using standard fabrication techniques and processes, simplifying the manufacturing workflow. This ease of processing contributes to improved production efficiency and cost-effectiveness.

Quality and Consistency:

As a product from DuPont, Pyralux AP 8545R undergoes rigorous quality control measures and testing to ensure consistent performance and adherence to industry standards. The material is manufactured with precision and consistency, reducing variability and ensuring reliable performance across production batches.

Applications and Industry Use Case

The Dupont PYRALUX AP 8545R is a flexible composite material that is often used in the electronics industry for a variety of applications. Some common uses of this material include:

1. Flexible Printed Circuit Boards (PCBs): PYRALUX AP 8545R is used as a substrate material for flexible PCBs, which are widely used in electronic devices such as smartphones, tablets, and wearables.

2. Flexible heaters: The material’s high thermal conductivity and flexibility make it suitable for use in flexible heaters, which are used in a variety of industrial and consumer applications.

3. Sensors and antennas: PYRALUX AP 8545R can be used as a substrate material for flexible sensors and antennas, which are used in applications such as automotive systems, medical devices, and IoT devices.

4. LED lighting: The material’s flexibility and high temperature resistance make it suitable for use in flexible LED lighting applications, such as automotive lighting and decorative lighting.

Overall, the Dupont PYRALUX AP 8545R is a versatile material that is widely used in the electronics industry for various applications that require flexibility, high temperature resistance, and reliability.

Manufacturing and Processing Considerations

When using DuPont Pyralux AP 8545R in manufacturing PCB boards, there are certain considerations and guidelines to ensure optimal processing and successful production. Here are some key manufacturing and processing considerations for working with Pyralux AP 8545R:

1. Handling and Storage Guidelines: Proper handling and storage of Pyralux AP 8545R are essential to maintain its performance and integrity. The material should be stored in a controlled environment, preferably in a cool and dry area, away from direct sunlight and excessive moisture. It should be protected from physical damage and contact with chemicals that may affect its properties.

2. Fabrication Techniques and Processes: Pyralux AP 8545R can be processed using standard fabrication techniques commonly employed for flexible circuit materials. These techniques include laminating, etching, drilling, and plating. It is important to follow the manufacturer’s recommended processing parameters, such as temperature, pressure, and exposure times, to ensure proper adhesion, precise circuitry formation, and dimensional stability.

3. Compatibility with Assembly Methods: Pyralux AP 8545R is compatible with various assembly methods commonly used in electronic manufacturing, including surface mount technology (SMT) and through-hole technology (THT). The material can be assembled using standard soldering techniques, such as reflow soldering or wave soldering, depending on the specific application requirements. It is important to ensure that the assembly processes and temperatures are compatible with the thermal characteristics of Pyralux AP 8545R to prevent damage or delamination.

4. Adhesive Cure and Bonding: Pyralux AP 8545R utilizes an acrylic adhesive system for bonding layers. Proper adhesive cure time and temperature are crucial to achieve optimum bonding strength and reliability. It is important to follow the manufacturer’s recommendations for adhesive cure profiles to ensure complete curing and proper adhesion between layers.

5. Surface Preparation: Before processing Pyralux AP 8545R, it is important to ensure that the substrate surfaces are clean and free from contaminants. Surface preparation techniques such as cleaning, abrasion, or plasma treatment may be required to ensure good adhesion and remove any impurities that could affect the performance of the material.

6. Test and Inspection: Quality control measures, including testing and inspection, should be implemented throughout the manufacturing process. This helps identify any defects, inconsistencies, or issues that may arise during fabrication, ensuring that only high-quality Pyralux AP 8545R circuits are produced.

By considering these manufacturing and processing guidelines, manufacturers can ensure the successful production high quality of Printed Circuit Board using DuPont Pyralux AP 8545R. Adhering to recommended procedures and best practices will help optimize the material’s performance, reliability, and overall quality.

Quality Control and Testing

Quality control and testing play a critical role in ensuring the reliability, performance, and consistency of electronic circuits manufactured using DuPont Pyralux AP 8545R. Here are some important aspects of quality control and testing for this material:

Material Testing and Certification:

DuPont Pyralux AP 8545R undergoes rigorous material testing and certification processes to ensure its compliance with industry standards and specifications. This includes testing its electrical, mechanical, and thermal properties, as well as assessing its adhesion strength, dimensional stability, and chemical resistance. The material may be certified to meet specific standards such as IPC-4101 or UL recognition, providing reassurance of its quality and suitability for various applications.

Reliability and Performance Evaluation:

Pyralux AP 8545R can be subjected to reliability and performance evaluation tests to assess its long-term durability and functionality. These tests may include thermal cycling, humidity testing, thermal shock, solderability testing, and mechanical stress testing. By subjecting the material to such assessments, manufacturers can ensure that it meets the required reliability standards and can withstand the anticipated operating conditions.

Dimensional Verification:

The dimensional stability and accuracy of Pyralux AP 8545R are crucial for ensuring proper fit and compatibility with other components and circuitry. Dimensional verification tests can be conducted to ensure that the material maintains its specified thickness, width, and length within acceptable tolerances. This helps prevent issues such as misalignment, short circuits, or mechanical failures during assembly and operation.

Adhesion and Bond Strength Testing:

The adhesive bonding between layers in Pyralux AP 8545R is critical for its overall integrity and performance. Adhesion and bond strength tests can be performed to evaluate the strength and reliability of the adhesive system. These tests assess factors such as peel strength, shear strength, and delamination resistance, ensuring that the material can withstand the mechanical stresses it may encounter during its lifetime.

Electrical Performance Testing:

Pyralux AP 8545R’s electrical properties, such as dielectric strength, insulation resistance, and impedance characteristics, can be evaluated through electrical performance testing. This includes tests such as dielectric constant measurement, insulation resistance measurement, and impedance characterization. These tests verify that the material meets the required electrical specifications and ensures proper signal transmission and integrity.

Statistical Process Control (SPC):

Implementing statistical process control techniques allows manufacturers to monitor and control the production process of Pyralux AP 8545R circuits. SPC involves collecting and analyzing data at various stages of the manufacturing process to identify any variations or deviations from the desired specifications. This enables early detection of potential issues and facilitates corrective actions, contributing to consistent quality and process improvement.

Comparison with Alternative Materials

DuPont Pyralux AP 8545R is a high-performance flexible circuit material, but it’s always valuable to compare it with alternative materials to understand the trade-offs and considerations. Here’s a comparison of Pyralux AP 8545R with some common alternative materials:

1. FR-4: FR-4 is a widely used rigid circuit board material made of a fiberglass-reinforced epoxy laminate. While FR-4 offers good mechanical strength and rigidity, it lacks the flexibility of Pyralux AP 8545R. Pyralux AP 8545R is designed for applications that require bending and flexing, making it suitable for applications where flexibility and miniaturization are essential.

2. Polyimide Films: Polyimide films, such as Kapton, are flexible circuit materials that share some similarities with Pyralux AP 8545R. Both materials offer excellent thermal stability and can withstand high temperatures. However, Pyralux AP 8545R has the advantage of an integrated adhesive system, which simplifies the lamination process and ensures consistent bonding between layers. Pyralux AP 8545R also offers better electrical performance and dimensional stability compared to some polyimide films.

3. Flexible Copper-Clad Laminates (FCCL): FCCL materials, also known as copper polyimide laminates, are commonly used in flexible circuit applications. They consist of a copper foil layer bonded to a polyimide film. While FCCL materials provide flexibility, Pyralux AP 8545R offers additional advantages such as superior thermal stability, better electrical properties, and compatibility with higher temperature environments. Pyralux AP 8545R is often preferred when applications require exceptional thermal and electrical performance.

4. Liquid Crystal Polymer (LCP): LCP is another alternative material used in flexible circuits. LCP offers excellent dimensional stability, high-temperature resistance, and good electrical performance. However, Pyralux AP 8545R provides superior flexibility and ease of processing. It also offers a wider range of thicknesses and is often preferred when applications require a balance between flexibility and advanced electrical and thermal properties.

When selecting a flexible circuit material, it’s essential to consider the specific requirements of the application. Factors such as flexibility, thermal stability, electrical performance, dimensional stability, ease of processing, and cost should be taken into account. DuPont Pyralux AP 8545R excels in providing a combination of excellent flexibility, thermal stability, electrical properties, and reliable performance, making it a preferred choice for demanding applications in various industries.

Conclusion

In the rapidly evolving electronics industry, choosing the appropriate flexible circuit board material is paramount. DuPont Pyralux AP 8545R meets manufacturers’ requirements for high-quality circuit boards with its exceptional flexibility, reliability, and superior performance. Whether in aerospace, consumer electronics, or medical devices, Pyralux AP 8545R showcases its unique value. By selecting Pyralux AP 8545R, you gain access to a dependable, flexible, and high-performance material that delivers exceptional performance and long-lasting reliability for your products.