Ventec VT-4B5L PCB materials are highly regarded in the electronics industry for their exceptional quality and performance. These advanced materials offer superior thermal conductivity, excellent dimensional stability, and outstanding electrical properties, making them ideal for demanding PCB applications. Manufacturers and engineers value the reliability and consistency of Ventec VT-4B5L laminates, which enable the production of high-quality printed circuit boards for various electronic devices and systems.

What Is Ventec VT-4B5L?

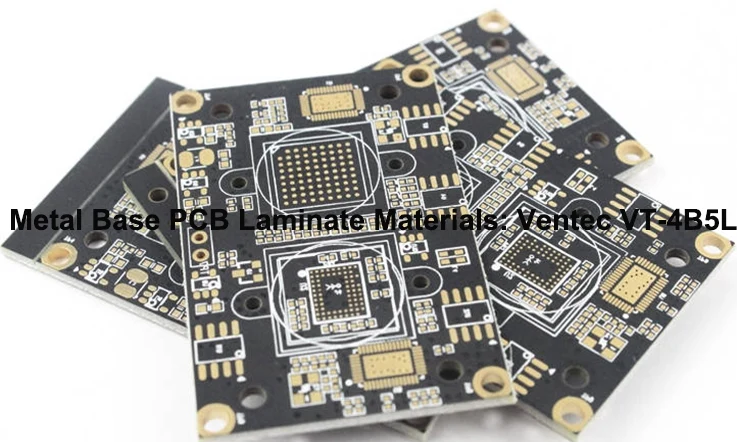

The Ventec VT-4B5L is a metal base laminate designed for high-performance printed circuit boards (PCBs). It is constructed with a metal substrate that provides excellent thermal conductivity and stability, making it suitable for applications requiring efficient heat dissipation.

The VT-4B5L laminate features a high-quality dielectric material with low thermal resistance, allowing for reliable and consistent performance in demanding thermal environments. It also offers excellent dimensional stability and mechanical strength, ensuring the integrity of the PCB during manufacturing and operation.

This metal base laminate is well-suited for use in power electronics, LED lighting, automotive, aerospace, and other high-reliability applications. Its combination of thermal management, electrical insulation, and mechanical durability makes it a versatile and reliable choice for advanced PCB designs.

Overall, the Ventec VT-4B5L metal base laminate provides a robust foundation for high-performance PCBs, offering thermal management and reliability for demanding applications.

Features Information of Ventec VT-4B5L PCB Materials

The Ventec VT-4B5L PCB material is characterized by its advanced features, making it a preferred choice for engineering applications:

Thermal Conductivity: The material exhibits an impressive thermal conductivity of 3.6 W/mK, ensuring efficient heat dissipation in electronic components.

Composition: Infused with ceramic fillers, the VT-4B5L demonstrates enhanced structural integrity and performance, meeting the stringent requirements of modern electronic designs.

Halogen-Free: Compliant with environmental considerations, the material is halogen-free, aligning with industry standards for eco-friendly manufacturing.

Flammability Rating: The VT-4B5L attains a UL94 V-0 flammability rating, emphasizing its robust resistance to combustion and providing an added layer of safety in electronic applications.

Solder Joint Crack Solution: Specifically engineered to address the challenge of solder joint cracks, this PCB material offers a reliable solution, ensuring the durability and longevity of solder connections.

This comprehensive set of attributes positions the Ventec VT-4B5L as a high-performance PCB material suitable for demanding electronic applications.

Performance of Ventec VT-4B5L

The Ventec VT-4B5L metal base laminate offers high-performance characteristics suitable for demanding applications. Some of its key performance features include:

1.Thermal Conductivity:

The metal substrate of the VT-4B5L provides excellent thermal conductivity, allowing for efficient heat dissipation. This is beneficial for applications requiring effective thermal management, such as power electronics and LED lighting.

2.Dielectric Properties:

The laminate features a high-quality dielectric material with low thermal resistance. This provides reliable electrical insulation and consistent performance in thermal environments, contributing to the overall reliability of the PCB.

3.Dimensional Stability:

The VT-4B5L offers excellent dimensional stability, ensuring that the PCB maintains its shape and integrity during manufacturing and operation. This is important for maintaining precise electrical and mechanical characteristics over time.

4.Mechanical Strength:

The laminate provides mechanical strength, which is important for withstanding the rigors of manufacturing processes and the demands of the application environment. This contributes to the durability and longevity of the PCB.

5.Versatility:

The VT-4B5L is suitable for a range of applications, including power electronics, LED lighting, automotive, and aerospace, highlighting its versatility and adaptability to diverse industry requirements.

Overall, the Ventec VT-4B5L metal base laminate offers a combination of thermal management, electrical insulation, and mechanical durability, making it a high-performance solution for advanced PCB designs.

Applications of Ventec VT-4B5L

The Ventec VT-4B5L PCB material is well-suited for a diverse range of applications, showcasing its adaptability and reliability in critical electronic systems. Key application areas include:

High Beam & Low Beam Systems:

The material’s thermal conductivity of 3.6 W/mK ensures effective heat dissipation, making it an ideal choice for applications like high beam and low beam lighting systems, where thermal management is crucial for optimal performance.

3D Lighting Systems:

Leveraging its ceramic-filled composition, the VT-4B5L excels in supporting intricate 3D lighting applications. The material’s structural integrity enhances the precision and reliability of complex lighting systems.

Power Conversion Systems:

In power conversion applications, the VT-4B5L’s halogen-free composition aligns with environmental standards while its thermal properties contribute to the efficiency and stability of power conversion processes.

Motor Drives & Controllers:

The material’s resilience and resistance to solder joint cracks make it well-suited for motor drives and controllers, ensuring the durability and consistent performance of these critical components.

Power Supply Units:

Addressing the stringent requirements of power supply units, the VT-4B5L’s UL94 V-0 flammability rating enhances safety, while its overall composition and thermal characteristics contribute to the reliability of power supply applications.

Compare with Other PCB Substrates Materials

When comparing the Ventec VT-4B5L metal base laminate with other PCB substrate materials, it’s essential to consider various factors such as thermal conductivity, dielectric properties, mechanical strength, and application suitability. Here’s a general comparison with commonly used PCB substrate materials:

FR-4:

FR-4 is a widely used epoxy-based substrate material known for its affordability and electrical insulation properties. However, it has lower thermal conductivity compared to metal base laminates like the VT-4B5L, making it less suitable for high-power applications where efficient heat dissipation is crucial.

Aluminum-based PCBs:

Aluminum-based PCBs offer good thermal conductivity and are often used for applications requiring heat dissipation. However, they may have limitations in terms of dielectric properties and mechanical strength compared to the VT-4B5L metal base laminate.

Ceramic-based PCBs:

Ceramic substrates provide excellent thermal conductivity and electrical insulation, making them suitable for high-temperature applications. However, they may be more brittle and less mechanically robust compared to metal base laminates.

Flexible PCB materials:

Flexible PCB materials offer the advantage of flexibility and space-saving design options. However, they typically have lower thermal conductivity and may not be as suitable for high-power applications as metal base laminates.

Therefore, the Ventec VT-4B5L metal base laminate stands out for its combination of high thermal conductivity, excellent dielectric properties, and mechanical strength, making it well-suited for demanding applications in industries such as power electronics, LED lighting, automotive, and aerospace. It offers a balanced set of characteristics that may be advantageous for applications requiring efficient heat dissipation, reliable electrical insulation, and mechanical durability.

How to Ensure Quality of Ventec VT-4B5L PCB Laminates?

To ensure the quality of Ventec VT-4B5L PCB laminates, here are some key considerations:

1. Supplier Selection: Choose a reputable and certified supplier for Ventec VT-4B5L PCB laminates. Verify that the supplier adheres to industry standards and has a track record of delivering high-quality materials.

2. Material Inspection: Perform thorough material inspection upon receipt of the Ventec VT-4B5L laminates. Check for any physical defects, such as delamination, warping, or surface irregularities. Ensure that the material meets the specified thickness and dimensional requirements.

3. Storage and Handling: Properly store and handle the Ventec VT-4B5L laminates to prevent exposure to moisture, contaminants, or excessive temperatures that could compromise the material’s quality.

4. Quality Control Testing: Conduct quality control testing, such as thermal conductivity measurements, dielectric strength tests, and dimensional stability assessments, to verify that the Ventec VT-4B5L laminates meet the required specifications.

5. Compliance with Standards: Ensure that the manufacturing processes adhere to industry standards and specific requirements for the application. Compliance with standards such as IPC-4101 for base materials and IPC-6012 for PCBs is crucial for ensuring quality.

By following these steps, manufacturers can help ensure the quality and reliability of Ventec VT-4B5L PCB laminates in their end products. Continuous monitoring, adherence to standards, and collaboration with suppliers are essential to maintaining high-quality materials throughout the PCB manufacturing process.

How to Find a Reliable Ventec series PCB Manufacturer?

Finding a reliable Ventec series PCB manufacturer involves conducting thorough research and evaluation of potential suppliers. Here are some steps to help identify a trustworthy manufacturer for Ventec series PCBs:

1. Certification and Compliance: Verify that the manufacturer holds relevant certifications and complies with industry standards. This may include certifications such as ISO 9001 for quality management systems, ISO 14001 for environmental management, and specific certifications related to PCB manufacturing, such as IPC-6012 for rigid PCBs.

2. Experience and Expertise: Evaluate the manufacturer’s experience and expertise in producing PCBs using Ventec materials. Look for evidence of successful projects, technical capabilities, and a deep understanding of the Ventec series laminates and their applications.

3. Quality Control Processes: Inquire about the manufacturer’s quality control processes, including material inspection, testing procedures, and compliance with Ventec’s specifications. A reliable manufacturer should have robust quality control measures in place to ensure the consistency and reliability of the PCBs they produce.

4. Collaboration with Ventec: Determine if the manufacturer has a collaborative relationship with Ventec or has access to technical support and guidance from Ventec. This collaboration can indicate a deeper understanding of Ventec materials and their optimal use in PCB manufacturing.

5.Facility Visits and Audits: If feasible, consider visiting the manufacturer’s facilities to assess their capabilities, production processes, and quality control measures.

By following these steps, you can identify a reliable Ventec series PCB manufacturer capable of delivering high-quality PCBs using Ventec materials for your specific application requirements. By the way, when choosing a suitable manufacturer for your PCB requirements, JarnisTech might be the best choice for your PCB project. Contact us now to discuss the next steps of the plan.

Conclusion

Ventec VT-4B5L PCB materials stand out as a top choice for achieving reliable and high-performance printed circuit boards. With their exceptional attributes and proven track record, these materials continue to be a preferred option for meeting the stringent requirements of modern electronics. By leveraging the capabilities of Ventec VT-4B5L laminates, manufacturers and designers can ensure the integrity and functionality of their electronic products, setting new standards for quality and performance in the industry.