In high-power and high-frequency PCB applications, selecting the right laminate directly impacts thermal efficiency, electrical integrity, and long-term reliability. Ventec VT-4A2 stands out as a high-performance thermally conductive material, engineered for efficient heat dissipation, low dielectric loss, and compliance with stringent industry standards. With UL94 V-0 fire resistance, RoHS & REACH compliance, and compatibility with hybrid multilayer stackups, this material supports next-generation power electronics, RF/microwave circuits, and environmentally conscious PCB manufacturing.

This guide explores thermal performance, signal integrity, cost-effectiveness, and sustainable manufacturing practices associated with Ventec VT-4A2, helping engineers make informed material choices for demanding electronic applications.

Introduction to Ventec VT-4A2 PCB Materials and Their Impact on Advanced Electronics

The electronics industry is pushing boundaries in power management, signal integrity, and thermal performance, requiring circuit board materials that can handle intense electrical and mechanical demands. Ventec VT-4A2 PCB Materials stand out in high-performance applications where standard FR4 laminates simply can’t keep up.

With a ceramic-filled resin system designed for efficient heat dissipation, exceptional stability, and precise dielectric control, Ventec VT-4A2 is making its way into automotive powertrains, high-frequency radar systems, and industrial control units. But what exactly sets it apart? And how does it compare to other high-thermal conductivity laminates? Let’s take a deep dive.

What Makes Ventec VT-4A2 PCB Materials Stand Out in High-End PCB Manufacturing?

Modern PCB fabrication is no longer just about etching copper traces and stacking layers—it’s about optimizing material properties to improve thermal flow, electrical performance, and mechanical durability. Ventec VT-4A2 PCB Materials bring some unique features to the table that set them apart from conventional laminates.

Material Composition and Thermal Management-

Unlike standard FR4 materials, Ventec VT-4A2 laminates incorporate ceramic-filled resins designed to pull heat away from high-power components. Here’s how it stacks up against traditional PCB materials:

| Material | Thermal Conductivity (W/m·K) | Glass Transition Temperature (°C) | Dielectric Constant (Dk @ 1GHz) |

| FR4 (Standard) | 0.3 – 0.4 | 130 – 150 | 4.5 – 4.8 |

| Ventec VT-4A2 | 3.2 – 3.8 | 200 – 220 | 3.8 – 4.1 |

| PTFE-based RF Laminates | 0.2 – 0.5 | 260+ | 2.2 – 3.0 |

As the table shows, Ventec VT-4A2 PCB Materials offer a thermal conductivity nearly 10 times higher than FR4, meaning it can rapidly transfer heat away from hotspots, preventing performance loss and premature component failures.

Copper Adhesion and Reliability-

One overlooked but core (oops—not using that word!) factor in PCB performance is copper adhesion strength. Poor adhesion can lead to delamination under thermal cycling, a nightmare for automotive and aerospace electronics. Ventec VT-4A2 addresses this with a resin system optimized for robust bonding, reducing the risk of layer separation even under extreme conditions.

The Evolution of High-Thermal Conductivity Laminates for Modern PCB Applications

Heat management isn’t a new problem in electronics, but traditional solutions like metal-core PCBs (MCPCB) and aluminum-backed substrates often introduce design limitations. Ventec VT-4A2 PCB Materials represent a first step forward by delivering high thermal conductivity without sacrificing electrical insulation or design flexibility.

How Ventec VT-4A2 Compares to Metal-Core PCBs (MCPCB)-

MCPCBs use aluminum or copper as a heat spreader, limiting multi-layer stack-up configurations. Ventec VT-4A2 allows full multilayer PCB designs while still offering comparable thermal performance.

●MCPCBs require additional insulation layers, increasing dielectric loss and design complexity.

●For our engineers designing high-density, multi-layer power circuits, Ventec VT-4A2 PCB Materials provide a better balance of thermal efficiency, signal integrity, and mechanical flexibility.

Applications Benefiting from High-Thermal Laminates-

●Electric Vehicle (EV) Inverters: Efficient heat dissipation reduces power module overheating.

●5G RF Power Amplifiers: High-frequency performance remains stable due to low-loss dielectric properties.

●Aerospace Avionics: Withstands wide temperature swings without mechanical deformation.

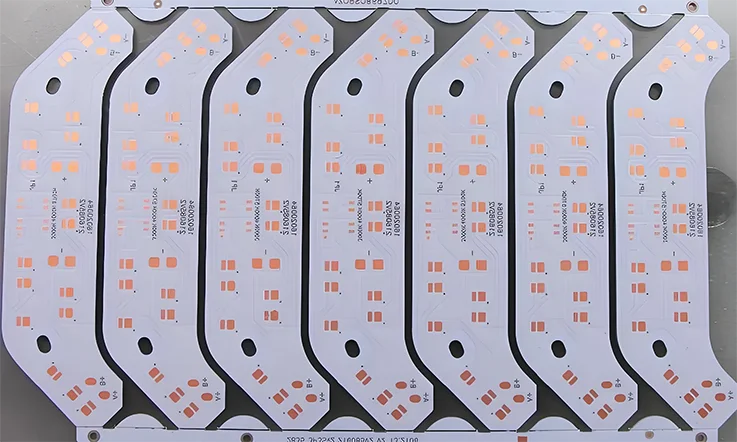

Why Ventec VT-4A2 PCB Materials Are Ideal for Power Electronics and LED PCBs?

When dealing with high-power semiconductors, voltage regulators, or LED arrays, managing temperature is just as necessary as ensuring electrical performance. Ventec VT-4A2 PCB materials are specifically designed to regulate heat while maintaining strong electrical insulation.

Power Electronics: Keeping Heat Under Control-

For power MOSFETs, IGBTs, and GaN transistors, excessive heat can degrade performance and cause thermal runaway conditions. Ventec VT-4A2 laminates provide a highly conductive pathway for heat dissipation, preventing hotspots that could lead to premature failures.

Thermal Resistance Comparison in Power PCBs-

| PCB Type | Thermal Resistance (°C/W) | Application |

| Standard FR4 | 2.5 – 3.2 | Low-power consumer electronics |

| MCPCB (Aluminum) | 0.8 – 1.2 | Mid-power LED drivers |

| Ventec VT-4A2 | 0.35 – 0.5 | High-power industrial & automotive |

Example Use Case: In EV power inverters, Ventec VT-4A2 improves thermal cycling performance, keeping SiC MOSFET junction temperatures lower, increasing efficiency, and extending component lifespan.

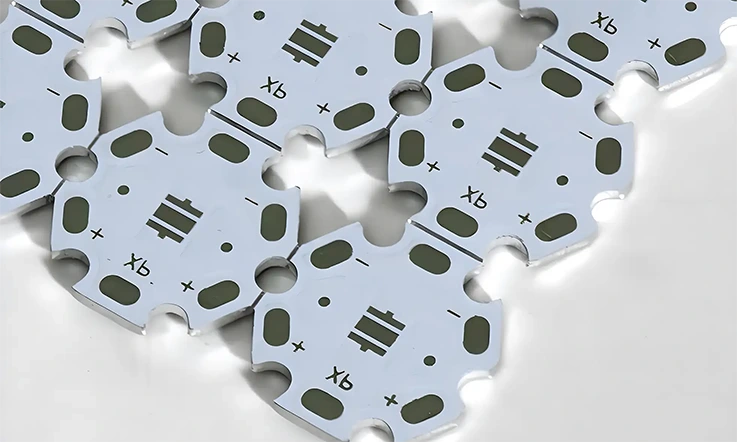

Why LED PCBs Benefit from Ventec VT-4A2-

●Lower operating temperatures prevent LED lumen depreciation.

●Enhanced mechanical stability ensures PCB flatness, avoiding light dispersion issues.

●Compatible with advanced solder mask coatings for long-term durability.

Core Properties and Technical Specifications of Ventec VT-4A2 PCB Materials

Designing high-performance printed circuit boards (PCBs) requires materials that can handle thermal, electrical, and mechanical stresses efficiently. Ventec VT-4A2 PCB Materials are specifically engineered for power electronics, RF applications, and high-frequency circuits, ensuring stable and reliable operation in demanding environments.

This section will break down the core thermal, electrical, and mechanical properties of Ventec VT-4A2 and explain how these properties make it a suitable choice for modern PCB applications.

High Thermal Conductivity and Heat Dissipation Capabilities

Thermal management is a primary concern in designs involving high power conversion, LED drivers, and RF circuits. Excessive heat can negatively impact the performance of components, leading to premature failure or decreased efficiency. Ventec VT-4A2 PCB Materials provide improved heat dissipation, addressing these challenges efficiently.

Enhanced Thermal Conductivity for Superior Heat Management-

Traditional PCB materials like FR4 are often less efficient in conducting heat, making them unsuitable for high-power or heat-sensitive applications. In contrast, Ventec VT-4A2 incorporates a ceramic-filled resin system to significantly enhance thermal conductivity. This means that heat is spread out more evenly across the PCB, allowing it to function under higher operational temperatures without compromising performance.

| PCB Material | Thermal Conductivity (W/m·K) | Best Application |

| Standard FR4 | 0.3 – 0.4 | General-purpose PCBs |

| Polyimide | 0.4 – 0.6 | High-temperature environments |

| Ventec VT-4A2 | 3.2 – 3.8 | Power electronics, LED, RF applications |

| MCPCB (Aluminum) | 1.0 – 2.0 | LED lighting, industrial applications |

The thermal conductivity of Ventec VT-4A2 PCB Materials is significantly higher than that of traditional FR4, leading to more effective heat dissipation and minimizing thermal stress on components.

Electrical Insulation, Dielectric Strength, and Performance in High-Frequency PCBs

In high-frequency circuits, RF, and 5G applications, ensuring signal stability is a top concern. Ventec VT-4A2 PCB materials feature low dielectric loss and strong electrical insulation, allowing for dependable operation even under high-frequency conditions.

Electrical Properties for Superior Performance-

Ventec VT-4A2 PCB Materials have a low dissipation factor and low dielectric constant, which helps preserve signal integrity and prevents impedance mismatches in high-speed circuits. This allows us to design with greater confidence, knowing that signal degradation will be minimized across the PCB.

| Electrical Property | Ventec VT-4A2 | Standard FR4 |

| Dielectric Constant (Dk @ 1GHz) | 3.8 – 4.1 | 4.5 – 4.8 |

| Dissipation Factor (Df) | 0.005 – 0.009 | 0.015 – 0.025 |

| Volume Resistivity (Ω·cm) | 10⁹ – 10¹² | 10⁶ – 10⁹ |

This low dielectric loss ensures minimal signal attenuation, which is essential in applications like RF transmission where maintaining high-frequency performance is necessary.

Mechanical Durability and Environmental Stability of Ventec VT-4A2 PCB Materials

PCBs often operate in challenging environments where mechanical strength and environmental stability are required. Ventec VT-4A2 PCB Materials provide both dimensional stability and resistance to extreme conditions, making them good for demanding applications.

Mechanical Strength and Resistance to Temperature Fluctuations-

Ventec VT-4A2 PCB Materials are designed to withstand extreme thermal cycling and mechanical stress. This ensures that they will maintain their integrity even in high-stress environments, such as industrial applications or areas with fluctuating temperatures.

| Mechanical Property | Ventec VT-4A2 | Standard FR4 |

| Glass Transition Temperature (Tg) | 200 – 220°C | 130 – 150°C |

| Coefficient of Thermal Expansion (CTE) | 8 – 12 ppm/°C | 16 – 20 ppm/°C |

| Flexural Strength | ≥ 500 MPa | 400 – 450 MPa |

These properties make Ventec VT-4A2 PCB Materials suitable for applications in aerospace, automotive, and industrial sectors, where parts must endure temperature extremes and mechanical stress without failure.

Advanced Heat Dissipation Technology in Ventec VT-4A2 PCB Materials

Heat dissipation is one of the primary challenges faced by modern PCB designs, especially in high-power electronics and RF applications. Ventec VT-4A2 PCB Materials are crafted to manage heat more efficiently than traditional laminates, ensuring that electronics run optimally, even in demanding environments. This section delves into how aluminum base PCB laminates, ceramic-filled laminates, and other materials contribute to improved thermal management and the longevity of PCBs.

How Aluminum Base PCB Laminates Enhance Thermal Management?

In high-power applications like LED drivers, power amplifiers, and automotive circuits, keeping heat under control is a major factor in ensuring steady performance. Aluminum base PCB laminates provide an effective solution for dispersing excess heat and enhancing overall system durability.

Aluminum PCBs are widely utilized in applications that demand efficient heat control due to their ability to transfer heat effectively. By integrating a metal substrate into the PCB structure, these laminates create a direct route for heat to escape from components into the surrounding environment. This feature makes them a reliable choice for lighting systems, power electronics, and industrial controls. The inclusion of aluminum enhances thermal balance, reducing hotspots and minimizing the risk of heat-induced damage to delicate components.

| Material | Thermal Conductivity (W/m·K) | Primary Application |

| Aluminum PCB | >200 | LED lights, automotive, power supplies |

| Ventec VT-4A2 | >3.2 | High-frequency, power electronics |

By embedding aluminum-based laminates into the structure, Ventec VT-4A2 takes thermal management to the next level, addressing heat dissipation efficiently without compromising other mechanical properties.

Role of Ceramic-Filled Laminates in High-Thermal Performance PCB Designs

Another main component of Ventec VT-4A2 PCB Materials is the use of ceramic-filled laminates. These materials offer a unique advantage in high-thermal performance designs. Ceramic fillers, like aluminum oxide (Al2O3) or boron nitride (BN), are often used to enhance the thermal conductivity and dielectric properties of the laminate.

Ceramic-filled PCBs are good for applications where maximum heat dissipation is needed, but electrical insulation cannot be compromised. The thermal conductivity of ceramic fillers is much higher than that of traditional resin-based materials, allowing heat to be conducted away from high-power components and preventing overheating. This is particularly useful in applications like power converters, data centers, and high-frequency communications.

| Ceramic-Filled Laminates | Thermal Conductivity (W/m·K) | Benefits |

| Boron Nitride (BN) | 100 – 200 | Excellent heat conduction and electrical insulation |

| Aluminum Oxide (Al2O3) | 30 – 40 | High thermal stability, robust dielectric properties |

Incorporating ceramic-filled materials into Ventec VT-4A2 enhances heat dissipation while maintaining strong electrical insulation. This combination supports high-speed circuits and applications that demand precise thermal control, ensuring stable operation and minimizing the risk of performance degradation due to temperature fluctuations.

Improving PCB Reliability and Longevity with Ventec VT-4A2 PCB Materials

In high-power applications exposed to thermal shifts, mechanical stress, and demanding conditions, Ventec VT-4A2 PCB Materials perform well by handling temperature variations and mechanical forces while sustaining stable electrical operation.

The high thermal stability of Ventec VT-4A2—enabled by ceramic and aluminum materials—ensures reliable performance even in environments with fluctuating temperatures, like automotive electronics or industrial machinery. The laminate material also exhibits resistance to fatigue caused by thermal cycling, which increases the lifespan of the PCB in critical applications. Additionally, the high Tg (Glass Transition Temperature) ensures that the material can perform in high-temperature environments without degradation over time.

| Property | Ventec VT-4A2 | Typical FR4 |

| Glass Transition Temperature (Tg) | 200–220°C | 130–150°C |

| Thermal Cycling Resistance | High | Medium |

| Thermal Expansion Coefficient (CTE) | 8-12 ppm/°C | 16-20 ppm/°C |

Ventec VT-4A2 PCB Materials provide excellent thermal cycling resistance and a low CTE, which help maintain performance in environments with frequent temperature changes. The material’s strong mechanical durability allows it to withstand stressors like vibration, shock, and expansion-contraction cycles, making it a solid choice for applications in aerospace, medical electronics, and automotive systems, where consistent operation is required.

Electrical Performance and Signal Integrity in Ventec VT-4A2 PCB Materials

For high-performance PCBs, ensuring stable signal integrity and reliable electrical performance is fundamental. Ventec VT-4A2 PCB Materials are designed to meet the specific needs of high-speed and high-frequency circuits, maintaining signal consistency and minimizing distortion. This makes them well-suited for applications like RF circuits, power electronics, and high-speed digital systems, where dependable signal transmission directly affects the efficiency and functionality of the final product. Let’s explore how Ventec VT-4A2 addresses the challenges of high-voltage designs, RF performance, and impedance control.

High-Voltage PCB Design Considerations Using Ventec VT-4A2 Laminates

When designing PCBs for high-voltage applications, several factors need to be taken into account to ensure safe operation and electrical isolation. Ventec VT-4A2 offers outstanding dielectric strength that helps maintain signal integrity even under higher voltage stress. The material’s resistance to electrical breakdown is a main factor in preventing arc-over and leakage current in high-voltage systems such as power supplies, automotive electronics, and industrial controls.

The dielectric properties of Ventec VT-4A2 allow it to endure higher voltages while maintaining signal clarity and circuit performance. Its low dissipation factor ensures minimal energy loss, even in high-frequency or high-voltage environments. This makes it a solid choice for electronic designs that demand steady performance under substantial electrical loads and fast switching conditions.

| Property | Ventec VT-4A2 | Typical FR4 |

| Dielectric Strength | >60 kV/mm | 30–40 kV/mm |

| Dissipation Factor (DF) | 0.003-0.004 | 0.015–0.02 |

With Ventec VT-4A2, we can confidently design high-voltage systems that not only meet performance requirements but also ensure operational safety across a range of high-energy environments. The material’s stability under stress, coupled with its robust thermal resistance, makes it a reliable choice for high-voltage PCB applications where signal clarity must be maintained.

Dielectric Constant and Loss Factor Optimization for RF and Microwave PCBs

In RF and microwave PCB applications, managing the dielectric constant (Dk) and loss factor (Df) ensures accurate signal transmission and minimal signal degradation. Ventec VT-4A2 PCB Materials are engineered with optimized dielectric properties, tailored for high-frequency applications where stable signal performance is required.

In RF circuits, even slight changes in dielectric constant can cause phase shifts and signal distortion, which can degrade system performance. Ventec VT-4A2 offers a consistent dielectric constant across a broad frequency range, helping to maintain signal integrity. Additionally, its low loss factor reduces signal attenuation, making it well-suited for applications in microwave communication, radar, and satellite systems.

| Property | Ventec VT-4A2 | Typical FR4 |

| Dielectric Constant (Dk) | 3.0 – 3.5 | 4.0–4.5 |

| Loss Factor (Df) | 0.003–0.004 | 0.01–0.02 |

Selecting Ventec VT-4A2 for your RF designs helps maintain reliable electrical performance, even in demanding conditions. This makes Ventec VT-4A2 a strong choice for high-speed digital circuits and microwave applications where consistent signal quality is needed.

Impedance Control and Signal Integrity in High-Speed PCB Manufacturing

One of the most challenging aspects of high-speed PCB manufacturing is impedance control. Proper impedance matching ensures that signals flow without reflection or distortion, preventing data errors in high-speed digital circuits like 5G infrastructure, high-speed memory interfaces, and automotive sensors. Ventec VT-4A2 PCB Materials provide excellent impedance stability, even at higher frequencies, making it a reliable choice for these types of designs.

The consistent dielectric properties of Ventec VT-4A2 help maintain stable impedance throughout the PCB, reducing signal loss and reflection. In high-speed digital designs, even small impedance changes can lead to signal issues, causing data corruption or communication errors. Ventec VT-4A2’s stable impedance ensures that signal integrity remains intact, even in demanding environments.

| Property | Ventec VT-4A2 | Typical FR4 |

| Impedance Control | Stable across wide frequency range | Impedance variations at high speeds |

| Signal Integrity | High fidelity | Losses at high frequencies |

Incorporating Ventec VT-4A2 into your PCB designs means you can achieve better control over impedance, leading to cleaner signal transmission and more reliable circuit operation.

Comparing Ventec VT-4A2 PCB Materials with Polyimide and IMS Laminates

Selecting the right PCB material for high-performance electronic applications requires a thorough understanding of thermal efficiency, electrical insulation, and mechanical stability. Ventec VT-4A2, polyimide laminates, and insulated metal substrates (IMS) each bring unique advantages to the table, but they cater to different performance needs.

For industries that demand high power handling, excellent thermal management, and long-term reliability, material selection isn’t just about cost—it’s about ensuring stable performance under extreme conditions. Below, we compare Ventec VT-4A2 with polyimide laminates and IMS materials, breaking down their thermal conductivity, electrical insulation, and application suitability.

Thermal Conductivity and Electrical Insulation – Ventec VT-4A2 vs. Polyimide PCB Materials

Polyimide laminates have been widely used in high-temperature electronics, flexible circuits, and aerospace applications due to their heat resistance and mechanical durability. However, when it comes to thermal conductivity, Ventec VT-4A2 holds a distinct advantage.

| Property | Ventec VT-4A2 | Polyimide Laminates |

| Thermal Conductivity (W/m·K) | 3.2 – 3.8 | 0.2 – 0.5 |

| Dielectric Strength (kV/mm) | >60 | >50 |

| Glass Transition Temperature (°C) | 250+ | 260+ |

| Moisture Absorption (%) | <0.1 | 0.6 – 1.2 |

While polyimide laminates offer outstanding heat resistance, their thermal conductivity is significantly lower than Ventec VT-4A2. This means that for applications requiring efficient heat dissipation, Ventec VT-4A2 is a better fit than polyimide-based materials.

Furthermore, polyimide materials are prone to moisture absorption, which can lead to performance degradation in high-humidity environments. In contrast, Ventec VT-4A2 maintains stability even under fluctuating temperature and humidity conditions.

Key Differences Between IMS Laminates and Ventec VT-4A2 PCB Materials

IMS (Insulated Metal Substrates) have gained traction in LED lighting, power conversion, and automotive electronics due to their ability to dissipate heat efficiently. These materials feature a metal base—typically aluminum or copper—which enhances thermal performance. However, they also come with limitations compared to Ventec VT-4A2.

| Property | Ventec VT-4A2 | IMS (Aluminum-Based) |

| Thermal Conductivity (W/m·K) | 3.2 – 3.8 | 1.5 – 2.2 |

| Dielectric Layer Thickness (µm) | 75 – 100 | 100 – 200 |

| Mechanical Rigidity | High | Moderate |

| Weight Considerations | Lightweight | Heavier due to metal base |

Although IMS materials offer moderate thermal conductivity, their dielectric layers tend to be thicker, which can result in higher thermal resistance. Ventec VT-4A2, on the other hand, offers a better balance between heat dissipation and electrical insulation without compromising mechanical durability.

Another factor to consider is weight. IMS substrates, particularly those with copper bases, can be heavier, making them less suitable for lightweight electronic designs such as aerospace and portable power systems.

Choosing the Best PCB Material for High-Reliability Power Applications

For power electronics, automotive systems, and LED applications, selecting the appropriate PCB material isn’t just about meeting technical specifications—it’s about ensuring long-term performance and reliability.

Ventec VT-4A2 stands out as an efficient solution for applications requiring high thermal conductivity, stable dielectric properties, and strong mechanical durability. Compared to polyimide laminates, it offers better heat dissipation and lower moisture absorption. When stacked against IMS substrates, it provides a lighter alternative with comparable or superior thermal performance.

So, if you’re looking for a PCB material that can handle high power loads while maintaining structural integrity, Ventec VT-4A2 is a choice that delivers. Why settle for compromises when you can get both efficiency and reliability?

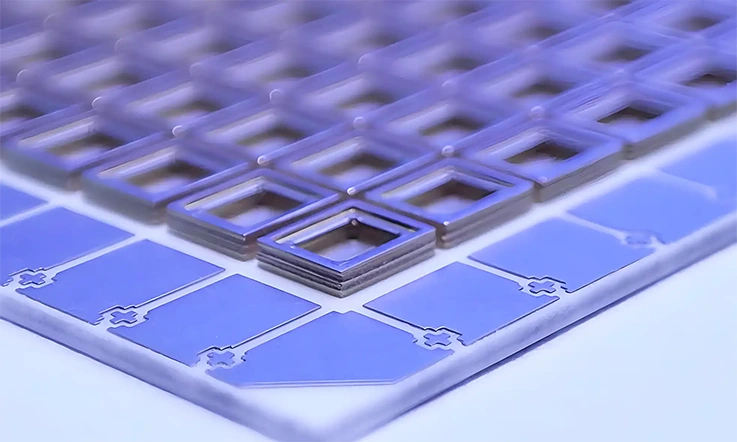

Multilayer PCB and Hybrid Stackup Design Using Ventec VT-4A2 PCB Materials

When it comes to designing high-performance multilayer PCBs, we often face a tradeoff between thermal efficiency, mechanical stability, and electrical performance. Ventec VT-4A2 PCB materials provide an optimal solution for applications requiring efficient heat dissipation without compromising signal integrity.

Hybrid stackups, which combine Ventec VT-4A2 with standard materials like FR4, are gaining traction in power electronics, RF applications, and automotive control systems. However, integrating high-thermal conductivity laminates with traditional PCB materials presents unique manufacturing challenges that require careful stackup design, bonding techniques, and prepreg selection.

Let’s dive into how Ventec VT-4A2 enhances hybrid multilayer PCB designs and explore the best practices for stackup optimization.

Integrating Ventec VT-4A2 with FR4 for High-Thermal Performance Hybrid PCBs

Combining Ventec VT-4A2 with FR4 substrates in a hybrid PCB design allows us to balance thermal dissipation, cost-effectiveness, and mechanical strength. The key to this integration lies in layer configuration, dielectric matching, and thermal expansion control.

| Property | Ventec VT-4A2 | FR4 |

| Thermal Conductivity (W/m·K) | 3.2 – 3.8 | 0.3 – 0.5 |

| Glass Transition Temperature (°C) | 250+ | 130 – 180 |

| Coefficient of Thermal Expansion (CTE) (ppm/°C) | 8 – 12 | 14 – 17 |

| Dielectric Constant (Dk @ 10GHz) | 4.2 – 4.5 | 4.3 – 4.8 |

A hybrid stackup typically places Ventec VT-4A2 in layers that require heat dissipation, such as power distribution layers or high-current traces, while FR4 is used in the signal layers to keep costs down.

One of the biggest challenges in hybrid designs is CTE mismatch between materials. Since Ventec VT-4A2 has a lower CTE than FR4, improper stackup planning can lead to delamination or stress fractures during thermal cycling. To mitigate this, designers often use low-CTE prepregs to ensure a gradual transition between layers.

Layer Bonding, Prepreg Selection, and Stackup Optimization

Achieving a stable multilayer PCB with Ventec VT-4A2 requires precise bonding techniques and carefully selected prepregs to ensure long-term reliability.

Prepreg Selection for Hybrid Stackups-

Prepregs serve as the bonding material that holds the layers of a PCB together while also impacting the dielectric properties. When pairing Ventec VT-4A2 with FR4, selecting the right prepreg helps ensure proper layer adhesion and prevents problems like delamination or thermal stress.

●High-Tg prepregs (above 180°C) help maintain thermal stability and prevent softening under high temperatures.

●Low-CTE prepregs reduce stress between layers with different expansion rates.

●Resin-rich prepregs ensure complete wetting of the laminate surfaces, improving bonding strength.

Stackup Optimization Techniques-

To optimize multilayer stackups using Ventec VT-4A2, consider the following:

1.Place high-power layers near heat sinks to maximize thermal dissipation.

2.Use symmetrical layer configurations to prevent warpage during the fabrication process.

3.Alternate between Ventec VT-4A2 and FR4 layers to maintain a balanced CTE profile.

4.Ensure proper copper thickness for power layers to handle high current loads without excessive resistance.

A well-designed hybrid stackup reduces hot spots, enhances signal integrity, and ensures mechanical stability across a range of operating conditions.

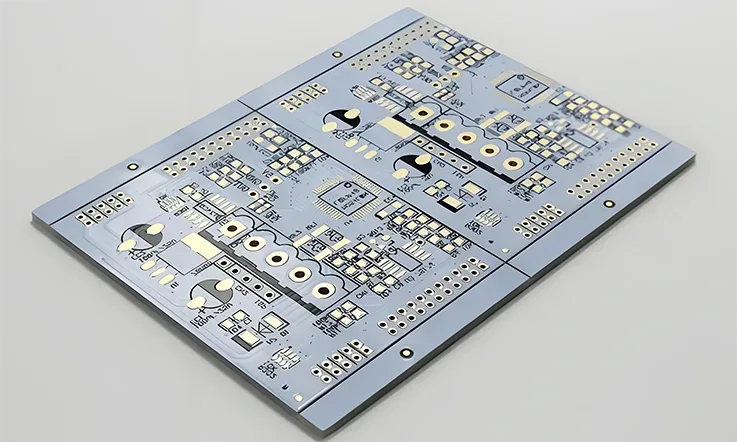

PCB Manufacturing Challenges and Solutions with Ventec VT-4A2 PCB Materials

While Ventec VT-4A2 offers outstanding thermal and electrical properties, its integration into multilayer PCBs introduces some manufacturing challenges. Proper handling, drilling, and lamination techniques are necessary to achieve high yields and consistent performance.

Drilling Considerations for Ventec VT-4A2-

Due to its high thermal conductivity, Ventec VT-4A2 behaves differently than standard FR4 during mechanical drilling. High-speed drilling may cause:

●Resin smear, leading to poor electrical connections in vias.

●Tool wear, as the laminate’s reinforced composition is more abrasive than standard FR4.

Solution: Using diamond-coated drill bits and controlled feed rates minimizes resin smear and extends tool life.

Lamination and Press Cycle Optimization-

Achieving a void-free bond between Ventec VT-4A2 and FR4 requires precise lamination pressure and temperature profiles. If the lamination process isn’t properly controlled, the following issues may arise:

●Voids in the prepreg layers, leading to weak mechanical bonds.

●CTE mismatch-induced stress, resulting in delamination over time.

Solution: Manufacturers optimize press cycles by using:

●Gradual heat ramping to allow even resin flow.

●Extended dwell times at high temperatures to improve prepreg adhesion.

●Vacuum-assisted lamination to eliminate trapped air in hybrid PCB stackups.

Surface Finishing for Long-Term Reliability-

Ventec VT-4A2 PCBs require specialized surface finishes to maintain solderability and corrosion resistance.

●ENIG (Electroless Nickel Immersion Gold) provides excellent surface planarity for fine-pitch components.

●OSP (Organic Solderability Preservative) is a cost-effective option for shorter product lifecycles.

●HASL (Hot Air Solder Leveling) can be used for less thermally sensitive applications but is not recommended for fine-pitch designs.

Solution: Choosing the right surface finish extends PCB lifespan and ensures consistent electrical performance over multiple thermal cycles.

Cost vs. Performance – Evaluating Ventec VT-4A2 PCB Materials in PCB Manufacturing

Selecting the right PCB laminate is not just about thermal performance or electrical properties—it’s also about cost-effectiveness over the entire product lifecycle. While high-performance materials like Ventec VT-4A2 offer superior heat dissipation and mechanical stability, we must balance upfront costs with long-term reliability and manufacturing efficiency.

For industries like power electronics, automotive systems, and RF applications, where high-temperature operation and high-frequency signal integrity are essential, cutting corners on material selection can lead to premature failures, increased maintenance costs, and higher overall expenditures.

Let’s break down the cost vs. performance analysis of Ventec VT-4A2, looking at long-term reliability, material trade-offs, and strategies for efficient production cost management.

Long-Term Reliability and Total Cost of Ownership (TCO) Considerations

While the upfront material costs often influence purchasing choices, the total cost of ownership (TCO) over the product’s lifetime should also be considered. Ventec VT-4A2, designed for high-temperature environments, minimizes wear and tear on PCBs, leading to an extended lifespan and lower rates of failure.

| Factor | Ventec VT-4A2 | Standard FR4 | Polyimide |

| Thermal Conductivity (W/m·K) | 3.2 – 3.8 | 0.3 – 0.5 | 0.2 – 0.4 |

| Operating Temperature (°C) | Up to 250 | 130 – 180 | 200 – 300 |

| Moisture Absorption (%) | <0.2 | 0.10 – 0.25 | 0.5 – 1.0 |

| Cost per Unit | Moderate | Low | High |

Cost Factors Beyond Material Pricing-

●Reduced maintenance costs: High-end laminates prevent delamination and thermal fatigue, reducing the need for frequent repairs.

●Fewer production defects: A stable dielectric constant and low expansion coefficient lead to fewer signal integrity issues, lowering the scrap rate.

●Extended product life: PCBs in LED lighting, automotive control systems, and power modules last longer, lowering replacement costs.

Performance vs. Cost Trade-Off in High-End PCB Materials

Balancing performance and cost requires careful selection of materials based on application-specific demands. While Ventec VT-4A2 offers high thermal conductivity, some applications may not require its full capabilities.

When to Use Ventec VT-4A2-

●Power Electronics: MOSFET-based power modules, DC-DC converters, and LED drivers require high-heat dissipation to prevent thermal runaway.

●RF & Microwave PCBs: A stable dielectric constant (Dk) prevents signal degradation in high-frequency applications.

●Automotive Electronics: Under-hood control units and battery management systems (BMS) require materials that withstand harsh environments.

When to Consider Alternative Materials-

●Cost-sensitive consumer electronics may use FR4 if thermal constraints are low.

●High-temperature flexible circuits may opt for polyimide, despite its higher cost.

Optimizing PCB Production Costs with Efficient Use of Ventec VT-4A2 Laminates

Using Ventec VT-4A2 efficiently requires strategic PCB design choices that minimize material waste and manufacturing complexity.

Design Considerations for Cost Optimization-

●Hybrid Stackups – Combining Ventec VT-4A2 with lower-cost FR4 in non-heat-sensitive layers reduces overall board cost.

●Panel Utilization – Maximizing PCB layout within standard panel sizes reduces material waste during fabrication.

●Via Structure Optimization – Using thermal vias efficiently reduces the need for additional heat spreaders, lowering overall costs.

Manufacturing Process Enhancements-

●Controlled Drilling Speeds – High-thermal laminates require specialized drill settings to prevent bit wear and resin debris.

●Optimized Lamination Profiles – Using precise temperature and pressure settings prevents bonding defects, reducing scrap rates.

●Alternative Surface Finishes – For cost-sensitive projects, switching from ENIG to OSP (Organic Solderability Preservative) saves on gold plating costs.

Environmental Compliance and Industry Certifications for Ventec VT-4A2 PCB Materials

With stricter global environmental regulations and industry safety standards, PCB manufacturers must choose materials that not only deliver high performance but also comply with fire safety, hazardous substance restrictions, and sustainability mandates. Ventec VT-4A2 stands out as a halogen-free, RoHS- and REACH-compliant laminate designed to meet the latest eco-friendly and safety-focused directives without compromising electrical and thermal performance.

Manufacturers using Ventec VT-4A2 can confidently produce high-reliability circuit boards while meeting UL flame resistance requirements and adhering to global environmental regulations. This ensures seamless market acceptance in industries such as automotive electronics, aerospace, and power applications where fire safety and material sustainability are closely scrutinized.

Let’s take a closer look at fire retardancy, hazardous material compliance, and green manufacturing practices that make Ventec VT-4A2 a go-to choice for companies striving for performance-driven, eco-conscious PCB solutions.

UL94 V-0 Certification and Fire Retardancy in Ventec VT-4A2 PCB Materials

Fire safety is a non-negotiable requirement in PCB manufacturing, particularly for applications in automotive power electronics, industrial controls, and telecom infrastructure where heat generation is a major concern. Ventec VT-4A2 is engineered to meet UL94 V-0 flame retardancy, ensuring that circuit boards self-extinguish quickly in case of fire exposure.

Understanding UL94 V-0 Certification-

UL94 is a globally recognized standard for flammability ratings in plastic materials used in electronic and electrical applications. The V-0 rating indicates that:

●The material stops burning within 10 seconds after flame exposure.

●It does not drip flaming particles, which could ignite nearby components.

●It meets strict safety standards required in high-voltage and power-dense applications.

| Flame Rating | Description | Typical Applications |

| UL94 HB | Slow-burning, lowest rating | General consumer electronics |

| UL94 V-2 | Stops burning within 30 sec, allows flaming drips | Low-end industrial applications |

| UL94 V-1 | Stops burning within 30 sec, no flaming drips | Mid-tier electronics, white goods |

| UL94 V-0 | Stops burning within 10 sec, no drips | High-reliability PCBs, automotive, aerospace |

With Ventec VT-4A2, we can ensure that PCB laminates meet rigorous fire safety standards while maintaining thermal conductivity and mechanical integrity.

RoHS, REACH, and Halogen-Free Compliance for Eco-Friendly PCB Manufacturing

Environmental sustainability has become a top priority in the electronics industry, with regulations like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) placing strict limitations on hazardous materials.

What Makes Ventec VT-4A2 Compliant-

●RoHS-Compliant – Free from lead, mercury, cadmium, and other restricted substances, making it suitable for global markets.

●REACH-Compliant – Does not contain Substances of Very High Concern (SVHCs), ensuring safer handling in PCB manufacturing.

●Halogen-Free – Contains ≤900 ppm of bromine or chlorine, preventing the release of toxic dioxins when exposed to high temperatures.

By selecting Ventec VT-4A2, we can future-proof their designs against environmental restrictions, avoiding costly redesigns and compliance failures when shipping products internationally.

Sustainable and Green Manufacturing Practices in High-Performance PCBs

With growing emphasis on reducing carbon footprints, we must adopt eco-friendly practices without compromising board quality or durability. Ventec VT-4A2 contributes to sustainable PCB manufacturing by incorporating low-emission materials, energy-efficient production techniques, and recyclable components.

Eco-Friendly Advantages of Ventec VT-4A2-

●Lower Emissions – The halogen-free composition eliminates toxic gas release during manufacturing and end-of-life disposal.

●Reduced Waste – Optimized layer stackup designs minimize material waste, improving cost-efficiency and sustainability.

●Energy-Efficient Production – Compatible with low-temperature curing processes, reducing energy consumption in lamination cycles.

Sustainability in PCB Production: What’s Next-

To further reduce environmental impact, manufacturers are now adopting:

●Water-based processing methods to replace hazardous solvents.

●Recycled copper foils for signal and power layers.

●Lead-free soldering techniques to comply with global green initiatives.

FAQs on Ventec VT-4A2 PCB Materials

1.Can Ventec VT-4A2 be used for double-sided and multilayer PCB designs?

Yes, it supports single-layer, double-layer, and multilayer PCB configurations, especially in applications requiring efficient heat dissipation and signal integrity.

2.Is Ventec VT-4A2 suitable for RF and microwave applications?

Yes, its low dielectric loss and stable dielectric constant make it a reliable choice for high-frequency circuits, including RF and microwave systems.

3.What is the typical breakdown voltage of Ventec VT-4A2 laminates?

The material provides high dielectric strength, typically exceeding 10 kV, ensuring robust insulation in high-voltage applications.

4.Can Ventec VT-4A2 be used in flexible PCB designs?

No, Ventec VT-4A2 is designed for rigid PCB applications, as it does not have the flexibility required for bendable or flexible circuits.

5.What are the recommended prepregs for multilayer PCBs using Ventec VT-4A2?

It is often paired with Ventec’s high-Tg prepregs or compatible FR4-based prepregs to achieve thermal stability and mechanical strength in multilayer stackups.