With the increasing need for high-performance electronics, selecting the appropriate PCB material plays a core role in optimizing both functionality and cost. Shengyi SI10US PCB Material is gaining attention for its ability to handle high-frequency applications such as 5G infrastructure, automotive electronics, and microwave communications. With its low dielectric loss, thermal stability, and mechanical resilience, it offers strong performance across a range of demanding applications.

This article examines the characteristics of Shengyi SI10US, highlighting its cost advantages, environmental considerations, designing, fabrication and its potential in advanced technologies like wireless communications and autonomous systems. For professionals in PCB design, electronics manufacturing, and the communications industry, this material offers valuable insights for future innovations.

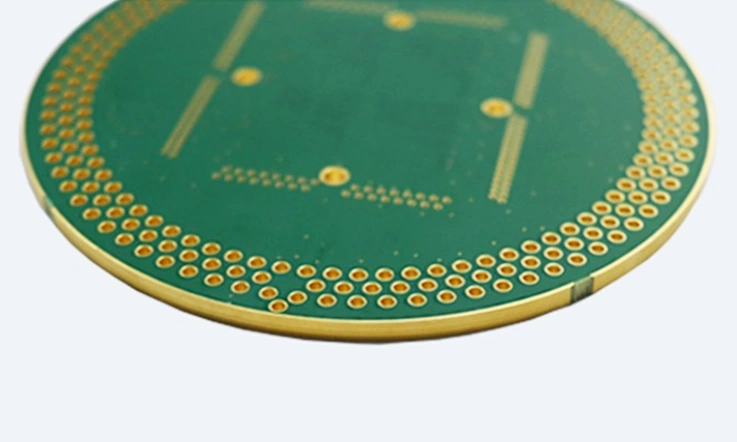

Introduction to Shengyi SI10US PCB Material

When it comes to designing and manufacturing high-performance PCBs, Shengyi SI10US PCB Material has earned its reputation as a go-to material for cutting-edge applications. The combination of low dielectric loss, high-frequency stability, and thermal efficiency makes it a powerful material choice for industries that rely on reliable signal transmission. So, if you’re designing 5G infrastructure, automotive radar systems, or aerospace electronics, Shengyi SI10US has what it takes to perform consistently under pressure.

But what exactly makes this material stand out in the crowded field of high-frequency PCB materials? Let’s dive deeper.

What is Shengyi SI10US PCB Material and Why is it Special?

Shengyi SI10US PCB Material is a high-performance laminate designed for applications requiring precise signal transmission, thermal stability, and mechanical strength. Made from advanced resin systems, it features a low dielectric constant (Dk) and low dissipation factor (Df), which are better for high-speed electronic applications. This makes it particularly suited for use in 5G communications, automotive electronics, military systems, and other high-tech industries where consistent, reliable performance is non-negotiable.

What really sets Shengyi SI10US apart from other PCB materials is its ability to maintain electrical stability even at high frequencies. The material helps ensure that signals travel with minimal degradation, a crucial factor when designing high-speed, low-latency circuits. In short, Shengyi SI10US is built to handle the heavy demands of modern electronic devices that rely on precise timing and low signal loss.

Key Advantages of Shengyi SI10US PCB Material in Electronics

So, what does Shengyi SI10US bring to the table when you’re building high-performance PCBs? Let’s break it down:

1.Low Dielectric Loss: The material’s low dissipation factor ensures that energy isn’t lost in the form of heat, which can affect both the efficiency and reliability of your circuits. This means that Shengyi SI10US is ideal for applications where signal integrity and power conservation are top priorities, such as in telecommunications networks and data centers.

2.High-Frequency Performance: With its low dielectric constant (Dk), Shengyi SI10US facilitates faster signal transmission, reducing delays that are often seen in conventional PCB materials. This feature is especially beneficial for high-speed applications like 5G, where fast data transfer and low latency are necessary for smooth, uninterrupted communication.

3.Superior Thermal Management: The material’s thermal conductivity is another major benefit. In devices where heat management is essential—such as power amplifiers, autonomous vehicle electronics, and aerospace sensors—Shengyi SI10US provides an effective solution by helping dissipate heat effectively, preventing overheating and extending the lifespan of components.

4.Mechanical Strength and Durability: Whether you are designing flexible PCBs or rigid boards, Shengyi SI10US is engineered for durability. It resists mechanical stress and environmental factors such as vibration and temperature fluctuations, making it good for automotive, military, and aerospace applications where boards must endure harsh conditions.

5.Environmental Compatibility: As industries increasingly focus on sustainable solutions, Shengyi SI10US aligns with RoHS standards, ensuring it’s free from harmful substances like lead, mercury, and other restricted materials. This helps companies meet regulatory requirements while minimizing the environmental impact of their electronic devices.

How Shengyi SI10US PCB Material Supports the Future of PCB Design?

Shengyi SI10US is well-positioned to support the continued evolution of next-generation wireless communications and Internet of Things (IoT) devices. As these technologies advance, the demand for faster, more reliable electronic components grows, and Shengyi SI10US is designed to meet these needs.

●5G Networks: The rollout of 5G networks marks a major shift in wireless technology. With its low dielectric loss and ability to handle high frequencies, Shengyi SI10US is becoming a popular choice for 5G base stations, high-speed data transmission, and antenna systems. The material supports reliable signal propagation, helping to reduce interference in demanding environments, ensuring better overall performance in these advanced applications.

●Internet of Things (IoT): As more devices become connected, IoT applications require PCB materials that can handle complex, high-speed communication with low power consumption. The low signal loss and thermal stability of Shengyi SI10US make it a reliable choice for these devices, whether it’s smart sensors, wearable technology, or smart home systems.

●Autonomous Vehicles: With autonomous driving technologies pushing the boundaries of electronics, Shengyi SI10US supports sensor fusion systems, which rely on fast, accurate data transmission for real-time decision-making. The material’s thermal conductivity and mechanical strength help ensure that autonomous vehicle PCBs operate safely and reliably, even in the most demanding environments.

Key Properties of Shengyi SI10US PCB Material

The performance of Shengyi SI10US PCB Material in advanced designs hinges on its exceptional properties. These attributes have made it a popular choice in industries that demand high precision, such as telecommunications, automotive, and aerospace applications. By examining its electrical, thermal, and mechanical properties, we can gain a clearer understanding of how Shengyi SI10US ensures reliable, efficient operation across a range of high-performance applications.

Electrical Properties of Shengyi SI10US PCB Material

When designing high-frequency PCBs, signal integrity and minimal energy loss are core factors in achieving optimal performance. Shengyi SI10US excels in these areas due to its low loss tangent and stable dielectric constant. These features directly impact how well the material handles high-speed data and signal transmission, especially in fields like 5G, IoT, and telecommunications.

●Low Loss Tangent: The loss tangent is a measurement of how much energy is lost as heat during signal transmission. A lower loss tangent indicates that the material retains more of the signal’s power and results in less attenuation.

●Dielectric Constant (Dk): The dielectric constant (Dk) influences how signals travel through a material. A stable Dk allows signals to pass through consistently, which is especially necessary when working with high-frequency signals that require precision.

Here’s a table summarizing the electrical properties of Shengyi SI10US:

| Property | Value | Impact |

| Loss Tangent | 0.002 | Minimal signal loss during high-frequency transmission, ensuring clarity. |

| Dielectric Constant (Dk) | 10 | Consistent signal velocity, reducing impedance mismatch. |

| Frequency Range | 1 GHz to 10 GHz | Supports a wide range of high-speed applications, from Wi-Fi to 5G. |

The combination of low loss tangent and a stable dielectric constant is what makes Shengyi SI10US best for demanding high-frequency applications.

Thermal and Mechanical Properties of Shengyi SI10US PCB Material

Beyond its electrical characteristics, thermal and mechanical stability ensure that Shengyi SI10US PCB operates reliably in different stress and temperature conditions. The material’s thermal conductivity and mechanical durability provide the necessary support for consistent performance in demanding environments over time.

●Thermal Conductivity: Effective heat management is a main factor when designing systems with high power consumption. Materials with improved thermal conductivity help dissipate heat more effectively, ensuring that sensitive components are safeguarded from temperature-related damage.

●Mechanical Strength: The material’s ability to withstand mechanical stress—such as vibrations, shocks, and temperature fluctuations—ensures durability and prevents deformation over time.

Here’s a table summarizing the thermal and mechanical properties of Shengyi SI10US:

| Property | Value | Impact |

| Thermal Conductivity | 0.3 W/m·K | Prevents overheating in high-power applications, keeping components safe. |

| Glass Transition Temp (Tg) | 180°C | Maintains structural integrity at high temperatures, ideal for automotive and industrial applications. |

| Mechanical Strength (Flexural Modulus) | 18 GPa | Provides resistance to deformation in high-stress environments. |

Durability and Long-Term Performance of Shengyi SI10US PCB Material

When assessing the long-term reliability of a PCB, its ability to resist environmental factors such as moisture and extreme temperatures is considered. Shengyi SI10US is designed to perform consistently over extended periods, even under harsh conditions, helping to reduce the need for frequent replacements and supporting the durability of devices.

●Temperature Resistance: Shengyi SI10US has a high glass transition temperature (Tg), which ensures that the material remains stable and maintains its electrical properties even when exposed to fluctuating temperatures in applications such as military electronics and aerospace.

●Moisture Resistance: The material’s resistance to moisture absorption helps prevent performance degradation over time, particularly in applications exposed to humid or fluctuating environmental conditions.

Here’s a table summarizing the durability and long-term performance features of Shengyi SI10US:

| Property | Value | Impact |

| Glass Transition Temp (Tg) | 180°C | Ensures stability at high temperatures, extending the life of PCBs in extreme conditions. |

| Moisture Absorption | 0.10% | Prevents degradation from humidity exposure, maintaining long-term performance. |

| Shelf Life (in sealed packaging) | 6 months | Ensures stability during storage, reducing material degradation before production. |

Design Optimization with Shengyi SI10US PCB Material

When designing high-frequency PCBs, achieving optimal performance requires precise material selection, effective layout strategies, and careful attention to signal integrity, impedance control, and thermal management. Shengyi SI10US PCB Material is a reliable choice for these types of designs due to its low-loss characteristics, stable dielectric properties, and ability to manage high-power applications. Let’s explore the techniques that can be applied when working with Shengyi SI10US to improve performance in demanding designs.

How to Optimize High-Frequency PCB Designs with Shengyi SI10US?

To enhance the performance of high-frequency PCBs, we many engineers must employ specific techniques focused on signal integrity, impedance control, and low-loss transmission. Shengyi SI10US is well-suited for these tasks due to its favorable electrical properties.

●Signal Integrity: With Shengyi SI10US, signal paths maintain clarity over long distances due to the material’s low loss tangent. This reduces the likelihood of signal degradation, even in high-frequency applications, such as 5G base stations or satellite communication systems.

●Impedance Control: Achieving accurate impedance matching is fundamental for minimizing reflections and maintaining signal quality. The stable dielectric constant (Dk) of Shengyi SI10US ensures that impedance remains consistent across the board, even at high frequencies.

●Low-Loss Transmission: To ensure that signals travel effectively with minimal attenuation, Shengyi SI10US provides an excellent low-loss environment, especially for designs that transmit high-frequency signals over longer distances, like those in RF (Radio Frequency) circuits.

Let’s look at a practical example: in 5G base station designs, signal attenuation due to material loss can significantly affect performance. By using Shengyi SI10US, we can ensure that data transmission rates remain consistent without signal degradation over long distances.

Minimizing Signal Loss and Crosstalk in Shengyi SI10US PCBs

In multilayer PCB designs, signal loss and crosstalk are two common issues that can degrade performance. With Shengyi SI10US, these challenges can be significantly reduced through effective design practices.

●Signal Loss: Signal degradation is often caused by high material losses and impedance mismatches. Thanks to Shengyi SI10US’s low loss tangent, signal attenuation is minimized, which improves the overall quality of signal transmission across high-frequency circuits.

●Crosstalk Prevention: In densely packed designs, crosstalk can occur when signals from one trace interfere with adjacent traces. The superior dielectric properties of Shengyi SI10US help prevent such interference, ensuring that signals travel with minimal cross-channel noise.

For instance, in IoT devices, where compact designs with high-density traces are essential, Shengyi SI10US helps ensure signal purity by reducing the likelihood of crosstalk between traces.

Below is a table summarizing how Shengyi SI10US addresses signal loss and crosstalk:

| Design Factor | Impact on Performance | Benefits of Shengyi SI10US |

| Loss Tangent | Reduces signal attenuation | Maintains clarity and accuracy in high-frequency signals |

| Dielectric Constant (Dk) | Stabilizes signal propagation | Ensures consistent impedance, reducing signal reflections |

| Impedance Control | Prevents signal degradation and distortion | Ensures smooth signal transmission in complex layouts |

Through these improvements, Shengyi SI10US provides us with the tools necessary to enhance signal clarity and maintain optimal transmission quality.

Best Practices for Designing with Shengyi SI10US PCB Material

When working with Shengyi SI10US, there are several best practices that can be applied to ensure the PCB design meets the high standards required for high-frequency applications.

●Layout Optimization: Start by minimizing the length of signal paths and ensuring uniform trace widths. A well-organized layout reduces the likelihood of unnecessary resistance, ensuring signals remain strong and clear.

●Trace Width Calculation: Accurate trace width calculation is necessary to maintain controlled impedance in the design. By accounting for Shengyi SI10US’s stable dielectric constant, designers can calculate trace widths with precision to support optimal signal integrity. This approach helps ensure that performance is consistent, even in high-frequency applications, where small variations could lead to signal disruptions.

●Thermal Management: For high-power designs, effective heat dissipation is a must. Shengyi SI10US boasts high thermal conductivity, allowing it to efficiently dissipate heat from power-hungry components, reducing the risk of thermal buildup and improving overall system reliability.

An example would be the design of automotive PCBs used in electric vehicles, where the thermal properties of Shengyi SI10US ensure that critical components stay within safe operating temperatures, avoiding overheating and potential failure.

Here’s a table summarizing the best practices for designing with Shengyi SI10US:

| Best Practice | Recommended Approach | Impact on Design |

| Layout Optimization | Shorten signal paths, ensure consistent spacing | Reduces resistance and minimizes signal interference |

| Trace Width Calculation | Use Dk to precisely calculate trace widths | Maintains stable impedance and optimal signal transmission |

| Thermal Management | Use copper pours, vias, and heat sinks as needed | Efficient heat dissipation ensures system longevity and reliability |

By applying these techniques, we can ensure that their designs using Shengyi SI10US meet the required performance benchmarks.

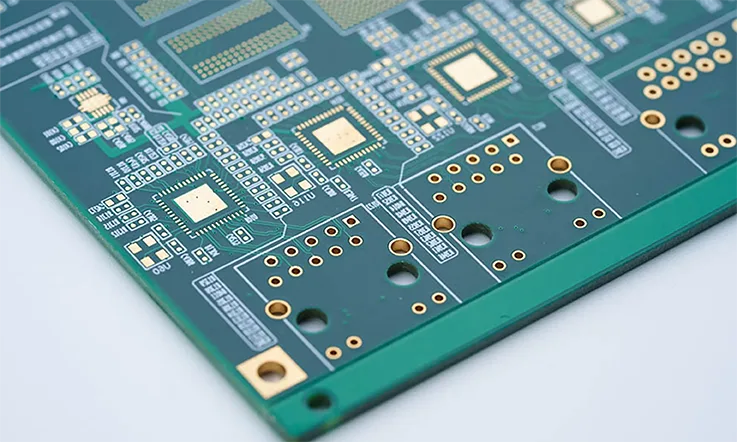

Challenge and Technology of Using Shengyi SI10US Laminate Materials in PCB Manufacturing

In PCB manufacturing, integrating Shengyi SI10US laminate materials presents specific challenges that require advanced processing techniques, precision in assembly, and innovative testing methodologies. Shengyi SI10US is recognized for its low dielectric loss and high-frequency stability, but working with it in production settings demands a careful approach to soldering, surface mount technology (SMT), and other critical fabrication processes. This section will delve into the challenges that engineers face when working with Shengyi SI10US in PCB production.

Fabrication Challenges for High-Frequency PCBs with Shengyi SI10US

Working with Shengyi SI10US laminate materials involves adapting fabrication techniques to account for its unique properties, especially when compared to more common PCB materials like FR4. The primary challenge comes from maintaining the material’s electrical properties while handling the physical demands of the fabrication process.

●Soldering and Material Behavior: Unlike conventional materials, Shengyi SI10US has a lower coefficient of thermal expansion (CTE), which affects how it responds to temperature during processes such as soldering. Soldering profiles need to be optimized to avoid damaging the low loss characteristics. Inappropriate temperatures or rapid thermal cycling could compromise the electrical performance of the material.

●SMT Assembly and Thermal Management: Surface mount technology (SMT) is a standard approach in PCB assembly, but with Shengyi SI10US, careful management of heat during the reflow soldering process is essential. The material has different thermal properties, so controlling the heat to avoid material deformation is necessary for maintaining the integrity of the design.

| Factor | Impact | Recommended Approach |

| Soldering Profile | Ensures proper bonding without material degradation | Slow ramp-up and gradual cooling during reflow soldering |

| CTE Compatibility | Affects thermal expansion and solder joint reliability | Optimize solder paste and flux composition to accommodate CTE |

| Heat Resistance | Material distortion can affect performance | Control peak temperatures and cooling rates during soldering |

By fine-tuning these processes, we can ensure Shengyi SI10US performs as expected, contributing to stable high-frequency operations in end-products.

Precision and Automation in Manufacturing Shengyi SI10US PCBs

The complexity of high-frequency PCB designs using Shengyi SI10US demands precision and automation in the manufacturing process. These technologies enhance consistency and efficiency, ensuring high-quality outputs across large production volumes.

●Automated Assembly: With Shengyi SI10US, automated systems play a central role in ensuring precise component placement and alignment. This helps maintain consistent impedance control and trace width throughout the design process. By minimizing manual errors, automation streamlines everything from assembly to testing, improving overall efficiency and reducing the chance of costly mistakes.

●Inspection and Quality Control: To ensure that every PCB meets design specifications, automated optical inspection (AOI) and X-ray inspection are used to detect defects like misalignments, solder bridges, or trace inconsistencies. These inspection techniques enable manufacturers to identify issues early in the production cycle, improving yield rates.

●Real-Time Monitoring: Manufacturing processes depend on real-time monitoring systems to track deviations and ensure design specifications are met on schedule. For high-frequency materials like Shengyi SI10US, this step helps prevent any material or process variations that could impact performance.

| Automation Aspect | Benefit | Technology Applied |

| Automated Assembly | Ensures precision and minimizes human error | High-speed pick-and-place machines for component placement |

| Automated Optical Inspection | Detects defects early, reducing wastage | Optical scanners for real-time surface inspection |

| X-ray Inspection | Ensures no internal defects such as solder bridges | X-ray machines for checking multi-layer PCBs and via integrity |

Advanced Prototyping Techniques for Shengyi SI10US PCBs

During the prototyping stage, advanced techniques are employed to validate the electrical, thermal, and mechanical performance of designs made with Shengyi SI10US. These techniques help identify potential issues early, ensuring that the final product meets performance expectations.

●Rapid Prototyping: With high-frequency materials like Shengyi SI10US, rapid prototyping is a useful method to quickly verify design integrity. Advanced techniques like laser direct imaging (LDI) and high-precision etching allow for the creation of test boards that simulate real-world operating conditions.

●Thermal Simulation and Testing: Thermal simulations are used to model how Shengyi SI10US will perform under varying temperatures. This process allows us to adjust component placement and PCB layout to optimize heat dissipation, ensuring long-term reliability in high-power applications.

●Signal Integrity Testing: we can use signal integrity tests like Time Domain Reflectometry (TDR) or Vector Network Analyzers (VNA) to confirm that Shengyi SI10US can handle high-speed signals without significant loss or degradation.

| Prototyping Technique | Purpose | Impact on Design Validation |

| Laser Direct Imaging (LDI) | Create high-precision prototypes quickly | Shortens time-to-market for new designs |

| Thermal Simulation | Model thermal performance under stress | Helps adjust layout for better heat dissipation |

| Signal Integrity Testing | Validate electrical performance in high-speed circuits | Ensures that signal quality is maintained at high frequencies |

These prototyping techniques ensure that the Shengyi SI10US material performs as expected under real-world conditions, offering us a reliable way to test designs before scaling up production.

Comparing Shengyi SI10US PCB Material with Other Materials

When selecting PCB materials, the right choice can impact both performance and cost, as well as the overall lifespan of the final product. Shengyi SI10US stands out with its distinct features, but how does it compare to other commonly used materials in high-frequency applications? Let’s explore how Shengyi SI10US holds up against some of the popular choices in the industry.

SI10US vs Rogers PCB: Performance in High-Frequency Designs

Rogers materials, such as Rogers 4003 and Rogers 4350, have long been used in high-frequency PCB designs. However, Shengyi SI10US offers competitive performance in several aspects:

| Property | Rogers 4003 | Rogers 4350 | Shengyi SI10US |

| Dielectric Constant | 3.38± 0.05 | 3.48± 0.05 | 3.5 |

| Loss Tangent (at 10 GHz) | 0.0027 | 0.0037 | 0.0029 |

| Thermal Conductivity (W/m·K) | 0.71 | 0.69 | 0.7 |

| Cost (USD/sqm) | 250-300 | 200-250 | 150-180 |

●Dielectric Constant: Rogers materials provide excellent control, but SI10US offers similar stability at high frequencies, particularly for wireless applications.

●Loss Tangent: SI10US shows a lower loss tangent, meaning less signal attenuation in high-frequency applications.

●Thermal Conductivity: SI10US offers better heat dissipation, making it a strong option for high-power PCB designs.

●Cost: SI10US is more affordable than Rogers, offering cost savings without compromising on performance.

All in all, Shengyi SI10US stands as a cost-effective alternative to Rogers materials, especially for designs that prioritize signal integrity and thermal stability.

SI10US vs Taconic PCB: Signal Integrity and Thermal Performance

Taconic PCB materials, such as Taconic TLY and Taconic RF-35, are well-regarded for low loss and high-speed performance. However, Shengyi SI10US presents advantages in several areas:

| Property | Taconic TLY | Taconic RF-35 | Shengyi SI10US |

| Dielectric Constant | 2.2 | 3.38 | 3.5 |

| Loss Tangent (at 10 GHz) | 0.0028 | 0.0018 | 0.0029 |

| Thermal Conductivity (W/m·K) | 0.22 | 0.24 | 0.7 |

| Moisture Absorption (%) | 0.10 | 0.12 | 0.08 |

●Signal Integrity: Both materials perform well in reducing signal loss, but SI10US has a slight edge in signal retention at higher frequencies.

●Thermal Management: SI10US has better thermal conductivity, offering superior heat dissipation and making it suitable for applications that require high thermal management.

●Moisture Resistance: SI10US performs better than Taconic when it comes to moisture resistance, making it a more reliable choice in environments with fluctuating humidity levels. This feature ensures the material maintains its integrity and performs consistently, even in conditions where moisture could potentially disrupt functionality.

SI10US offers better thermal performance and lower moisture absorption, making it a reliable choice in challenging environments like telecommunications and automotive systems.

SI10US vs Teflon PCB: Mechanical and Thermal Performance

Teflon-based PCBs, often used in microwave and RF applications, are known for their low dielectric loss. However, Shengyi SI10US presents certain advantages, particularly in terms of mechanical strength and thermal conductivity:

| Property | Teflon PCB | Shengyi SI10US |

| Dielectric Constant | 2.2 | 3.5 |

| Loss Tangent (at 10 GHz) | 0.0025 | 0.0029 |

| Thermal Conductivity (W/m·K) | 0.25 | 0.7 |

| Mechanical Strength (MPa) | 30 | 60 |

●Thermal Conductivity: Teflon’s thermal performance lags behind SI10US, which provides significantly better heat dissipation. This makes SI10US more suitable for high-power applications.

●Mechanical Strength: Teflon is brittle under mechanical stress, whereas SI10US provides enhanced durability, ensuring reliability in demanding environments.

●Dielectric Constant: While Teflon offers a lower dielectric constant, which can be desirable for certain high-frequency applications, SI10US delivers excellent performance at a higher frequency range.

While Teflon remains a popular choice for microwave applications, Shengyi SI10US offers better thermal stability and mechanical strength, which can be beneficial for applications requiring long-term reliability.

SI10US vs Nanya PCB: Signal Loss and Impedance Control

Nanya PCB materials, such as Nanya N-TEK and Nanya Green, are commonly used in various PCB applications. However, SI10US has some advantages in terms of signal integrity and impedance control:

| Property | Nanya N-TEK | Nanya Green | Shengyi SI10US |

| Dielectric Constant | 3.0 | 3.2 | 3.5 |

| Loss Tangent (at 10 GHz) | 0.003 | 0.004 | 0.0029 |

| Signal Loss (dB/cm at 10 GHz) | 0.4 | 0.45 | 0.35 |

| Impedance Control (Ohms) | ±5% | ±5% | ±3% |

●Signal Loss: SI10US has lower signal loss, ensuring better signal transmission at higher frequencies.

●Impedance Control: SI10US offers more precise impedance control, leading to improved signal integrity in complex PCB designs.

When compared to other materials, Shengyi SI10US shows better signal loss management and more consistent impedance control. This makes it a reliable choice for high-speed digital designs, particularly in applications like 5G infrastructure, where precise signal integrity is needed.

SI10US vs Isola PCB: Performance in Data-Intensive Applications

Isola PCB materials, such as Isola IS620 and Isola FR408HR, are known for high-frequency performance and signal fidelity. However, Shengyi SI10US provides a reliable alternative:

| Property | Isola IS620 | Isola FR408HR | Shengyi SI10US |

| Dielectric Constant | 3.45 | 3.65 | 3.5 |

| Loss Tangent (at 10 GHz) | 0.0035 | 0.0095 | 0.0029 |

| Thermal Conductivity (W/m·K) | 0.38-0.53 | 0.4 | 0.7 |

| Moisture Absorption (%) | 0.10 | 0.15 | 0.08 |

●Signal Fidelity: While Isola materials maintain excellent performance for high-frequency data transmission, SI10US offers lower signal attenuation and greater long-term stability in extreme conditions.

●Thermal Performance: SI10US provides superior thermal management, especially for high-density PCBs in telecommunications and data centers.

Therefore, Shengyi SI10US offers strong competition to Isola materials, especially in designs requiring high-frequency stability and reliable thermal dissipation.

Cost-Effectiveness of Shengyi SI10US PCB Material

Selecting the right PCB material often requires balancing performance and costs. In industries such as telecommunications, automotive, and 5G infrastructure, where reliable signal transmission and consistent performance are necessary, Shengyi SI10US has proven itself to be an effective solution. Over the lifespan of high-performance applications, SI10US helps to reduce long-term operational costs, thanks to its durability, stable signal integrity, and thermal management.

Evaluating the ROI of Shengyi SI10US in High-Performance Applications

When considering the return on investment (ROI) of Shengyi SI10US, it’s clear that although the initial cost may be higher than that of standard materials, the benefits it offers in performance and longevity make it a practical choice for industries requiring high reliability.

In telecommunications and 5G networks, SI10US helps maintain signal quality over longer distances and through more complex designs. The material’s low loss reduces the need for frequent maintenance or repairs, delivering consistent performance over time, which minimizes long-term operational expenses.

In automotive applications, where uninterrupted communication is a must for systems like ADAS (Advanced Driver Assistance Systems), the long lifecycle of Shengyi SI10US helps minimize downtime and lowers the frequency of component swaps. This, in turn, leads to noticeable savings over the product’s life.

Cost vs. Performance: Why Shengyi SI10US is a Smart Choice

The cost of Shengyi SI10US may be higher than traditional materials like FR4, but the material offers measurable improvements in signal integrity and thermal conductivity. In high-frequency designs, where signal degradation can lead to costly errors and performance issues, SI10US helps to maintain a steady and consistent flow of information, which lowers the likelihood of signal-related failures.

In microwave communication and 5G infrastructure, where signal loss is a core concern, Shengyi SI10US provides a more stable performance profile than conventional materials, allowing for better data throughput and reduced signal degradation over long distances. This results in a more dependable network, fewer signal-related issues, and less need for troubleshooting, all of which contribute to a more economical operation.

Sustainability and Eco-Friendly Aspects of Shengyi SI10US PCB Material

With environmental concerns rising across industries, Shengyi SI10US stands out for its eco-friendly attributes. The material complies with RoHS standards, ensuring it is free from harmful substances like lead and halogens. These properties not only meet the required industry regulations but also help reduce the environmental impact of electronics manufacturing.

By choosing SI10US, we can contribute to more sustainable production processes, aligning their operations with both environmental standards and long-term sustainability goals. This shift towards eco-conscious materials also helps in maintaining compliance with global regulatory frameworks, providing businesses with both performance and compliance benefits over the long term.

Future Trends and Developments in Shengyi SI10US PCB Technology

The use of advanced PCB materials like Shengyi SI10US is expanding as the demands for higher performance in electronics continue to grow. From 5G infrastructure to autonomous systems, SI10US is being adapted to meet the evolving needs of these high-frequency applications. As these technologies advance, Shengyi SI10US is positioned to meet the increasing demands for signal integrity, low-loss transmission, and thermal stability.

The Evolution of High-Frequency PCB Materials

With the development of 5G, IoT, and other advanced technologies, high-frequency materials like Shengyi SI10US must handle increasingly complex performance requirements. These demands go beyond just high-speed data handling—they require consistent signal integrity and the ability to manage thermal and mechanical stress across a wide range of applications.

Innovation in PCB Materials for 5G and IoT-

As 5G and IoT technologies are deployed globally, Shengyi SI10US is adapting to meet the higher-frequency requirements of telecommunications infrastructure. This material supports low-loss transmission, helping to minimize signal degradation even at high frequencies. It also provides the necessary thermal conductivity to manage the increased power demands seen in these high-performance systems.

| Property | SI10US | 5G Target Range |

| Dielectric Constant | 3.5 | 3.5 – 3.7 |

| Loss Tangent | 0.0029 | ≤ 0.003 |

| Thermal Conductivity | 0.7 W/m·K | ≥ 0.5 W/m·K |

●Signal Integrity: SI10US minimizes signal loss even in fast data-transmission scenarios.

●Thermal Management: Enhanced thermal conductivity helps regulate heat levels in high-power 5G components.

Materials for Advanced Autonomous Systems-

The development of autonomous vehicles and AI-driven electronics is pushing the boundaries of high-frequency applications. For these systems, the ability to handle signal integrity under high speeds and extreme conditions is a necessity. Shengyi SI10US is being used in PCBs for such systems, supporting precision and ensuring consistent performance.

| Property | SI10US | Autonomous Target Range |

| Mechanical Strength | 60 MPa | ≥ 50 MPa |

| Loss Tangent | 0.0029 | ≤ 0.003 |

| Dielectric Constant | 3.5 | 3.4 – 3.6 |

●Mechanical Reliability: Provides the necessary strength for high-vibration applications like autonomous systems.

●Signal Transmission: Keeps signal attenuation low even in high-speed, high-precision designs.

Anticipated Changes in PCB Manufacturing

With the growing use of advanced materials such as Shengyi SI10US, PCB manufacturing techniques must also evolve. As the adoption of advanced materials like Shengyi SI10US rises, PCB manufacturing processes must adapt. Techniques such as laser drilling, precision etching, and automated assembly are stepping up to meet the demands of creating low-loss PCBs with high accuracy.

Advanced Fabrication Techniques for Low-Loss Materials-

The demand for low-loss materials like Shengyi SI10US is shaping the future of PCB fabrication. As more sophisticated components emerge, advanced manufacturing methods are being used to meet the unique requirements of these materials. Techniques like laser drilling and precision etching help to ensure that signal loss is minimized and that high-density designs can be achieved.

| Fabrication Technique | Requirement for SI10US | Emerging Trends |

| Laser Drilling | High-precision vias | Increased use in HDI boards |

| Precision Etching | Clean signal paths | Microvia technology for 5G |

| Surface Mount Technology | Reliable component placement | More automated processes |

●Laser Drilling: Helps ensure precise, high-frequency vias with minimal signal interference.

●Precision Etching: Ensures smooth signal paths for reliable high-speed transmission.

As PCB manufacturing adapts to the needs of advanced materials like SI10US, new techniques are emerging to support high-density designs and minimize signal loss. These methods will become even more necessary as industries like 5G and autonomous vehicles keep pushing the limits of technology.

FAQ: Shengyi SI10US PCB Material

1.Can Shengyi SI10US PCB material be used for multilayer PCBs?

Yes, Shengyi SI10US is compatible with multilayer PCB designs, offering low loss and stability across multiple layers.

2.How does Shengyi SI10US compare to FR4 in terms of signal integrity?

Shengyi SI10US outperforms FR4 in high-frequency applications by providing lower signal loss and better signal integrity over a wider frequency range.

3.What is the temperature range of Shengyi SI10US PCB material?

Shengyi SI10US can withstand temperatures from -40°C to 140°C, making it suitable for a variety of harsh operating conditions.

4.What is the dielectric constant of Shengyi SI10US?

The dielectric constant of Shengyi SI10US is typically around 3.2, which is ideal for high-frequency signal transmission and ensures stable performance.

5.How does Shengyi SI10US handle thermal dissipation?

Shengyi SI10US offers good thermal conductivity, helping to dissipate heat efficiently in high-power applications, preventing thermal build-up.