Consignment PCB assembly is a popular solution for businesses seeking to outsource their printed circuit board assembly needs. This approach involves clients sourcing and procuring all the necessary components and then providing them to the assembly company for the final assembly process. This allows clients to have greater control over the manufacturing process and enhances their understanding of the constituent components and the assembly process.

In this article, we will delve deeper into the benefits of consignment PCB assembly, the mounting options available, and how JarnisTech’s services can help businesses streamline their PCB assembly needs.

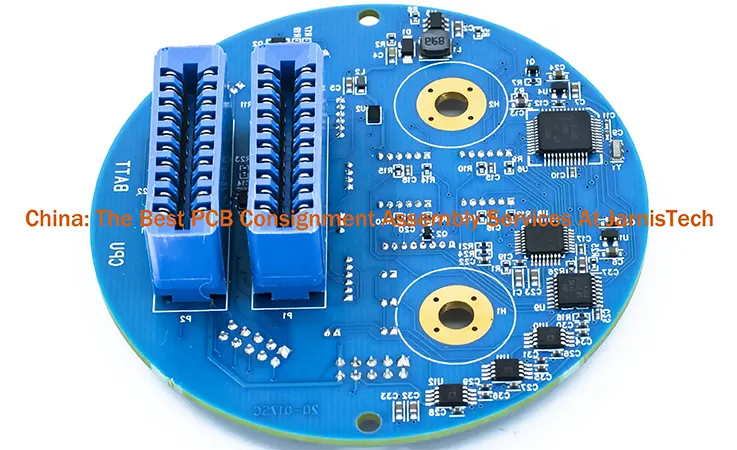

JarnisTech’s Consignment Assembly Service

In traditional turnkey printed circuit board assembly (PCBA), the manufacturer handles the entire process from sourcing components to assembly and testing. However, consignment PCB assembly is a more adaptable solution in which customers provide all necessary parts and components for assembly.

Consignment PCB assembly offers a mutually beneficial arrangement for both the customer and manufacturer. It provides customers with the flexibility and versatility required for PCB assembly and prototyping, while enabling manufacturers to ensure the fastest turnaround time.

At JarnisTech Electronics, we possess extensive expertise in consignment PCB manufacturing assembly, which empowers our customers to supply the required parts while still maintaining cost-effectiveness. This approach facilitates a rapid product launch for our customers.

Types of Consignment PCB Assembly

There are several types of consignment PCB assembly:

Full Consignment Assembly: In this type of consignment assembly, the customer provides all the required components, including the PCB, electronic components, and any necessary documentation. The assembly company provides the labor and equipment required to assemble the board.

Partial Consignment Assembly: In this type of consignment assembly, the customer provides some of the required components, such as the PCB or the electronic components, while the assembly company provides the remaining components and the assembly labor and equipment.

Kitted Assembly: In kitted assembly, the customer provides all the required components, but in a kit form. The assembly company provides the labor and equipment required to assemble the board.

Each type of consignment PCB assembly has its own advantages and disadvantages, depending on the customer’s requirements and preferences. It is important to choose the right type of consignment assembly to ensure the best quality, efficiency, and cost-effectiveness.

Difference Between Turnkey PCB Assembly and Consigned PCB Assembly

Once you have completed the design phase of your electronics product, the next step is to create a functioning prototype and bring it to market through volume production. To achieve this, you will need to engage the services of a professional who can handle the printed circuit board (PCB) fabrication and assembly. There are two primary approaches available to you at this stage of the project, each with its own cost/benefit and risk/reward considerations.

You can opt to have your electronic manufacturing completed by either a turnkey provider or a consignment provider. It is essential to carefully evaluate each option to ensure that you select the one that best aligns with your needs and business strategy.

Turnkey Assembly

Pros:

The process of manufacturing a printed circuit board (PCB) involves several intricate steps, including circuit board printing and storage, component ordering and warehousing, assembly, and thorough testing to ensure that the final product meets the desired specifications. Transforming a PCB into a successful product requires the installation and shipping of the final product, which can be quite a daunting task.

By leveraging the services of a full turnkey PCB assembly provider, you can outsource all of these complex steps and free up your time to focus on designing innovative products and managing your business operations. This approach allows manufacturing professionals to handle all the aspects outside your area of expertise. With a turnkey manufacturer, you can rely on a single point of contact for any issues or changes that need to be addressed, without the hassle of communicating with multiple vendors to resolve problems.

In addition to simplifying communication, using a turnkey manufacturer can also reduce lead times by eliminating the need for you to procure parts from various suppliers. By sourcing and assembling all necessary components in-house, a turnkey manufacturer can streamline the entire process, resulting in faster production times and a more efficient supply chain.

Cons:

Collaborating with a turnkey manufacturer involves entrusting them with the responsibility of managing the entire production process of your product. Some enterprises may exhibit apprehension towards relinquishing control over their manufacturing operations to an external party. However, selecting a trustworthy manufacturer guarantees that your product will be handled with utmost professionalism. It is essential to thoroughly evaluate various service providers and be self-assured in opting for a turnkey solution.

Consignment Assembly Services

In consignment assembly, the onus is on you to procure and warehouse all the necessary components for your PCB boards. It is imperative to maintain meticulous inventory records to ensure the smooth assembly of your product. Following this, you must pack and dispatch the components to the assembly company. While this approach provides a certain degree of control, it also places a significant burden on your staff to ensure seamless manufacturing operations. It is crucial to evaluate the impact of this approach on the overall manufacture of your product.

Pros:

The extent of control that a company seeks to exert over the manufacturing process after the design phase varies depending on their perspective. Nonetheless, if a reputable turnkey provider with a proven track record of delivering quality work is engaged, it is reasonable to trust that they will ensure that the components meet or exceed the specified requirements and tolerances. However, introducing a third-party manufacturer implies relinquishing control over the entire process. For those who prefer to exercise meticulous control over every aspect of the manufacturing process and have the necessary resources to manage the consignment approach, it is a viable option.

Cons:

Opting for consignment assembly entails assuming a considerable amount of supplementary responsibilities. These include allocating adequate storage space for components, supervising inventory management and procurement of each part, managing multiple supply chains, and sorting, packing, and dispatching the components to the assembly company. This necessitates additional staffing, financial resources, and expertise, which may not be feasible for every business to undertake. Furthermore, any disruption in the supply chain or operational mishaps could potentially arise, necessitating the need for troubleshooting. This means that the consignment approach involves handling several diverse aspects of the process, which requires conscientious problem-solving skills.

How Consignment PCB Assembly Works ?

Consignment PCB assembly is a process where a customer provides all the necessary components and materials to an assembly house, who then assemble and test the printed circuit board (PCB) according to the customer’s specifications. Here are the steps involved in a typical consignment PCB assembly process:

1. Customer provides the assembly house with a bill of materials (BOM) that includes all the necessary components, their quantities, reference designators, and any other specific requirements.

2. The customer also provides the assembly house with the PCB design files, including the Gerber files, pick-and-place files, and assembly drawings. These files are used by the assembly house to program their automated assembly machines and equipment.

3. The assembly house then verifies the BOM and PCB design files to ensure that all the required components and materials are available and match the specified requirements.

4. The customer ships the components and materials to the assembly house, who then inspects and records the received materials.

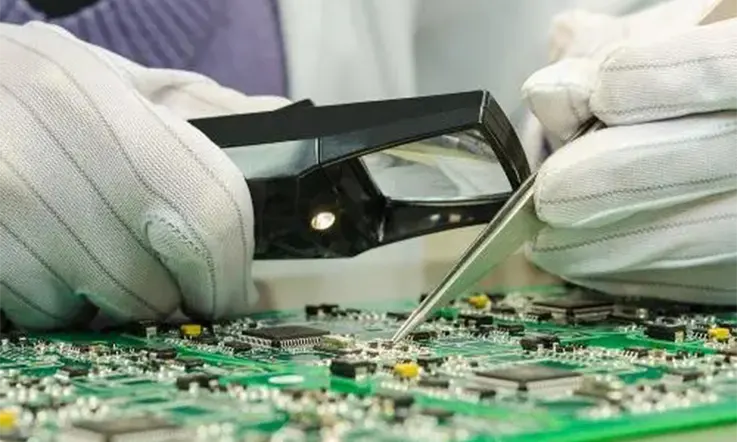

5. The assembly house then prepares the components for assembly, which may include cutting and forming the leads of through-hole components, taping and reeling the surface-mount components, and programming any required microcontrollers or other chips.

6. The components are then loaded onto the assembly machines, which place them on the PCB according to the pick-and-place files.

7. The assembled PCBs are then sent through a soldering process, which can be done using various methods such as wave soldering, reflow soldering, or hand soldering.

8. Once the soldering process is complete, the assembled PCBs are inspected both visually and with automated equipment to ensure that all the components are properly placed and soldered.

9. The assembled PCBs are then tested to ensure that they meet the customer’s specifications and functions as intended.

10. The completed PCBs are then packaged and shipped back to the customer.

Overall, the consignment PCB assembly process allows customers to have more control over the selection and quality of components used in their PCBs, but also requires them to manage the procurement and logistics of providing those components to the assembly house.

Factors to Consider when Choosing a Consignment PCB Assembly Provider

Choosing the right consignment PCB assembly provider is important to ensure that your PCBs are assembled accurately and efficiently. Here are some factors to consider when selecting a consignment PCB assembly provider:

Experience and Expertise: Look for an assembly house that has a proven track record of successful consignment PCB assembly projects. They should have experienced personnel with expertise in PCB design, assembly, and testing.

Quality Control and Certifications: Check if the assembly house has a quality control system in place and if they are certified to industry standards such as ISO 9001 or IPC-A-610. This ensures that the assembled PCBs meet the required quality standards.

Equipment and Technology: The assembly house should have modern and well-maintained equipment such as pick-and-place machines, soldering machines, and testing equipment. They should also have the ability to handle a wide range of component sizes and types.

Flexibility and Customization: The assembly house should be able to accommodate your specific requirements such as custom packaging, labeling, and testing procedures. They should also be able to work with a wide range of component suppliers to source the required components.

Communication and Collaboration: Look for an assembly house that communicates effectively and collaborates with you throughout the assembly process. They should be able to provide regular updates on the project status and be responsive to any questions or concerns you may have.

Cost and Lead Time: Consider the cost and lead time of the assembly house’s services. Look for a provider that offers competitive pricing while maintaining quality standards. They should also be able to meet your required lead time for the project.

Location and Shipping: Consider the assembly house’s location and shipping capabilities. Choose a provider that is conveniently located and has reliable shipping options to minimize shipping time and costs.

All in All, selecting the right consignment PCB assembly provider requires careful consideration of these factors to ensure that your project is completed successfully and efficiently.

Why You Should Choose JarnisTech ?

JarnisTech’s consignment PCB assembly services offer a slew of benefits that set us apart from our competitors. Our advanced automated equipment enables us to provide quick lead times, which reduces production time and boosts efficiency. The use of automation also minimizes the probability of errors, enhancing product accuracy and consistency in our assembling processes.

Furthermore, outsourcing consignment PCB assembly components results in reduced production expenses, making our services cost-effective. We subject all our products to a rigorous quality inspection process to ensure that our clients receive only the highest quality products. Our 5-step quality inspection process includes FAI, AOI, X-ray Inspection, FQA, and Function Test, which removes any errors that may have occurred during the PCB assembly process.

At JarnisTech, we prioritize providing the best-in-class consignment PCB assembly services to our global clientele. Our unmatched PCB assembling knowledge and skilled personnel have enabled us to become the leading consignment PCB assembly service provider globally. We adopt a customer-oriented approach that has resulted in a 99% customer satisfaction rate. If you are searching for a service provider that offers high-quality consignment PCB assembly services at competitive prices, JarnisTech is your go-to option.

JarnisTech’s Consigned PCB Assembly Capabilities

Jarnistech offers consignment PCB assembly services that prioritize the customer’s needs for flexibility and autonomy throughout the circuit board prototyping and assembly process.

We collaborate with our clients to identify optimal components that align with their design and application requirements. The clients then procure these components and furnish them to us, after which we complete the prototyping assembly process. This approach enhances the client’s comprehension of the printed circuit board assembly process and the constituent components.

Jarnistech delivers comprehensive assembly solutions by offering diverse mounting technology options. Our consignment capabilities encompass the following:

● SMT or PTH technologies or mixed.

● Leaded or lead free assembly processes.

● Single or double-sided mixed technology quick turn PCB assembly

● Prototype specialists for quick turns.

● Quick turn prototype PCB manufacturing.

● Single or double sided assemblies upon request.

● State-of-the art assembly equipment and methods.

● On time delivery and single point of customer service.

Tips for a Successful Consignment PCB Assembly

Consignment PCB assembly requires coordination between the customer and the assembly house to ensure that the project is completed successfully. Here are some tips for a successful consignment PCB assembly:

Provide Accurate and Complete Information: Provide the assembly house with accurate and complete information such as the bill of materials, PCB design files, and any specific requirements. This ensures that the assembly house has all the necessary information to assemble the PCBs correctly.

Verify Component Availability: Before shipping the components to the assembly house, verify that they are available and match the specified requirements. This helps to avoid delays and additional costs due to missing or incorrect components.

Label Components and Packaging: Label the components and packaging with reference designators to ensure that they are matched to the correct locations on the PCB. This makes it easier for the assembly house to identify and place the components correctly.

Choose Reliable Component Suppliers: Choose reliable component suppliers to ensure that the components are of high quality and meet the required specifications. This helps to avoid issues such as component failures or inconsistencies.

Communicate Regularly: Communicate regularly with the assembly house to ensure that the project is progressing as planned. Provide updates on component availability and any changes to the project requirements.

Test and Verify: Test and verify the assembled PCBs to ensure that they meet the required specifications and functions as intended. This helps to identify any issues early and avoid costly rework or delays.

Plan for Logistics and Shipping: Plan for logistics and shipping in advance to ensure that the components and assembled PCBs are shipped and delivered on time and in good condition.

As a result, following these tips can help to ensure a successful consignment PCB assembly project and minimize the risk of delays or quality issues.

Final Thought

Consignment PCB assembly is a process where a customer provides all the necessary components and materials to an assembly house, who then assemble and test the printed circuit board (PCB) according to the customer’s specifications. This approach offers several advantages such as increased control over component selection and quality, reduced inventory costs, and the ability to work with multiple assembly houses.

To ensure a successful consignment PCB assembly project, it is important to choose the right assembly house, provide accurate and complete information, verify component availability, label components and packaging, communicate regularly, test and verify the assembled PCBs, and plan for logistics and shipping.

In addition, the demand for consignment PCB assembly is expected to grow as more companies seek to reduce costs and increase efficiency in their PCB manufacturing processes. Advances in automation and machine learning are also expected to drive innovation in the assembly process, leading to faster and more accurate assembly of PCBs.

In a words, consignment PCB assembly is a valuable option for companies that require high-quality PCBs that are assembled to their exact specifications. By following best practices and working with a reliable assembly house, customers can achieve their desired results and improve their bottom line.

Related Posts:

- Mixed PCB Assembly Technology Services For Your Next New Project

- Why Electronic Potting is So Important in PCB Assembly?

- A Full Guide to Electro mechanical Assemblies

- Cable and Wire Harness Assembly

- Electronics Components PCB Assembly

- What Is Printed Circuit Boards Assembly?

- PCB Box Build Assembly

- Nine Method of Save Cost PCB Assembly Production

- How Many Types of Turnkey PCB Assembly?