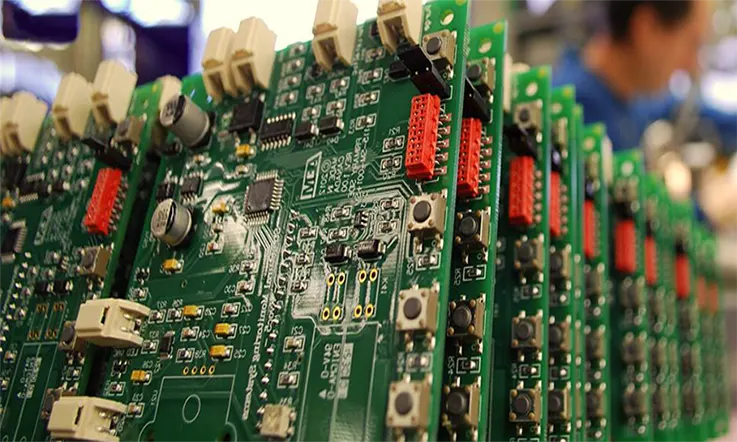

In today’s highly competitive industrial landscape, engineers are constantly seeking out innovative means of reducing the cost of their products without compromising on quality. Printed Circuit Boards (PCBs) are a crucial component of electronic and electrical engineering hardware, and their cost has a substantial impact on the price of the final product. Therefore, selecting a cost-effective PCB assembler and manufacturer that offers superior quality at reasonable prices is vital.

However, it has come to our attention that several providers offering cost-effective prototype PCB assemblies compromise on quality, resulting in product failures and noncompliance. To strike a balance between the cost and quality of PCB assembly, it is imperative that customers scrutinize the portfolio, services, and terms & conditions offered by each PCB assembler. Customers must also bear in mind their financial constraints while selecting an assembler and optimize their circuit design or PCB layout during the design phase.

To reduce the cost of PCB assembly effectively, customers must be cognizant of the challenges of cost optimization and quality control. By following these guidelines and collaborating with a reliable PCB assembler and manufacturer, customers can cut costs while ensuring that the quality of their products meets or exceeds their expectations.

What Factors Contribute to the High Cost of PCB Assembly ?

The cost of PCB design and production is influenced by various factors such as the intricacy of the design, the types of parts used, and the overall efficiency of the project. Additionally, the complexity and characteristics of the circuit are crucial elements that impact the total cost of PCB construction. Furthermore, the quality of PCB design can play a vital role in the final price.

The use of leadless components, coupled with precise pitching, adds to the overall expense of the PCB assembly. This is primarily due to the need for distinct testing procedures and a unique assembly process. The cost of essential components is also a significant factor contributing to the high cost of PCB assembly. The fabrication and assembly of printed circuit boards (PCBs) are reliant on sophisticated technology that caters to the demands of various industries. Consequently, the cost of PCB assembly is directly dependent on the firms, products, and assembly strategies involved.

Furthermore, there are three critical aspects related to the cost of the PCB that must be considered during PCB assembly:

● High-cost raw materials can lead to increased PCB production expenses.

● Unforeseen abnormalities that arise during production necessitate retesting at every stage of the assembly process.

● The assembling process has a significant impact on both the performance and cost of the resulting PCB.

How Can I Have Professionals Reduce PCB Assembly Cost ?

The cost of printed circuit board (PCB) assembly is frequently influenced by multiple factors, including the quantity and type of components and the intricacies of the assembly process. Different PCB assembly providers may use distinct pricing methods, causing pricing variations to occur.

Despite having no control over the assembly process, specific design strategies may be leveraged to reduce the overall cost of PCB assembly. By implementing such tactics, you can achieve your cost-effective goals and successfully reduce PCB assembly expenditures.

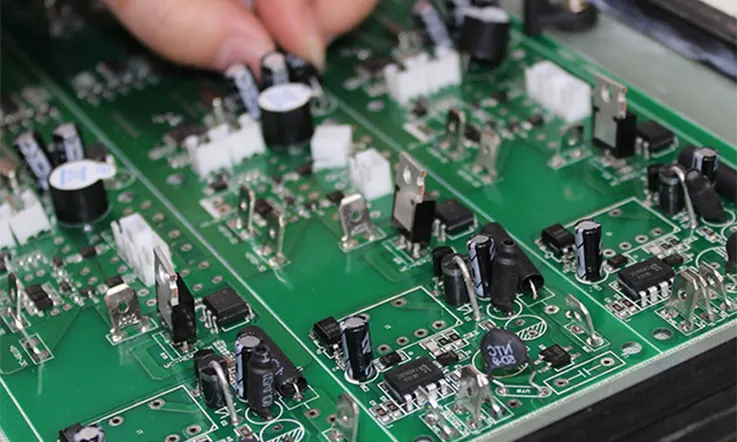

● Putting Surface-mount Parts on Just One Side: The cost of manufacturing a printed circuit board (PCB) with surface-mounted devices (SMD) on both sides is typically higher than that of a PCB assembly with SMDs on one side. This is because the process requires only a single pick and place setup iteration, resulting in significant cost savings for the stencil.

● Proper Designator Labeling: Designators are an essential component of PCB layout as they aid in component identification on the printed circuit board. They should be positioned in proximity to the corresponding components and be easily recognizable. The inclusion of designators simplifies the setup process for PCB assemblers and reduces the likelihood of issues arising during hand placement.

● Panelize The PCB: For mass production of circuit boards (PCBs), it is advisable to produce them in panels to reduce costs and streamline the assembly process. Manufacturing multiple iterations of the same printed circuit board (PCB) in a single panel reduces the number of PCB assembly runs.

During the pick and place process, it is crucial to ensure that the PCB panels contain sufficient fiducial markers to maintain accurate orientation. Fiducial markers are visual cues that aid in effective pick and place machine operation, and their inclusion in the PCB panel is highly recommended for maintaining precision in automated assembly processes.

● Give A Full BOM List: Generating a Bill of Materials (BOM) is a critical step during PCB layout development. This step is often considered less crucial than Gerber generation; however, it holds more significance. BOM assists the assembler by enabling them to place components on the appropriate footprint. It also aids in procurement planning and budgeting by allowing optimization of quantity and usage.

Generated by a designer, BOM files are essential for PCB assemblers to acquire the correct components and materials and initiate PCB assembly. Incomplete BOM files may lead to unnecessary delays and the procurement of inappropriate components, resulting in wasted time and expenses. The BOM should include the name of the supplier and manufacturer, part number, quantity, reference designator, and details regarding the parts and package footprint.

Several PCB assemblers offer their own BOM generation forms. When completed by the designer and provided to the assembler, it leads to a faster assembly process. Moreover, designers should consider providing alternative component replacement options, including replacement part numbers on the BOM. While constructing a circuit, a specific IC package may no longer be available on the market, making finding an alternative replacement a difficult task. Providing alternatives saves the assembler’s time searching for parts that are no longer accessible, reducing delays in production.

● Adjust Order Quantity: Order volume plays a significant role in reducing the overall costs of a PCBA. In general, the cost per unit decreases as larger quantities are ordered, whereas smaller quantities result in higher per-unit costs. This holds true for both bare and populated PCBs, as well as electronic components such as ICs, resistors, and capacitors. Therefore, there exists an inverse relationship between cost and quantity or order volume.

It is crucial to ensure that the PCB assembler can deliver your required specifications while also considering your order quantity requirements. When developing prototypes in quantities of 1 to 5 pieces, the cost per piece unavoidably tends to be higher compared to bulk or higher-volume orders.

● SMT Assembly Price is Cheaper Than Through-hole Assembly: Most modern electronic production facilities utilize Automated Surface Mount Technology (SMT), as it is a cheaper production method in terms of labor cost for custom PCB board production.

While hand placement is still used for Through-Hole Technology (THT), which has been in use since the inception of the industry, it is now mostly supplanted by SMT technology. Although certain connections that are subject to heavy stress, such as power connections, may still require THT, for the most part, SMT has taken over.

It is essential to minimize the number of through-hole operations in the manufacturing process as it contributes to higher costs for custom PCB design. In conclusion, the use of SMT has become the preferred technology, owing to its cost-effectiveness in modern PCB assembly manufacturing.

● Design Complexity: In order to minimize costs during PCB assembly, it is advisable to keep the layout complexity to a minimum. Additional work for the manufacturer, required to realize elaborate designs, can increase costs. One example is ensuring that all components are located on the same side of the circuit board, avoiding the need for surface mounting twice.

However, complexity may be unavoidable in certain instances. For instance, further scrutiny may be required for the inspection of specific design elements like ball grid arrays (BGAs). Similarly, some elements like conformal coating might necessitate an additional assembly phase, despite being necessary. This coating protects mining equipment and medical instruments from dust and vibration but is unfortunately often expensive.

● Lead Time: Expedited PCB orders entail a higher cost, akin to that of the United States Postal Service. If an ECM or bare PCB boards is given a shorter turnaround time to complete the project, it will charge a higher rate. In such cases, the producer may need to source resources from within the United States instead of other countries, thereby incurring higher costs. Unfortunately, manufacturing costs in the United States are higher than those in China, as widely acknowledged.

Moreover, the choice of components influences the lead time. By specifying readily available components that are already in stock, it becomes easier for the contractor to expedite the project completion process.

● Outsourcing Your PCB Services: Many business owners mistakenly believe that assuming as many responsibilities as possible themselves can save costs. However, this DIY approach often falls short in the long run. Despite potentially spending less initially, production delays, design flaws, and other factors can increase overall costs. The equipment and materials used in-house may not match the quality that outsourcing to a professional PCB manufacturer can provide. Ultimately, partnering with a PCB manufacturer can offer access to superior tools, high-quality products, and overall cost reductions.

While managing costs is a valid concern, it should not impede PCB initiatives. Contact us today to learn more about our services.

Importance of Cost-saving in PCB Assembly Production

Cost-saving in PCB assembly production is important because it directly impacts the profitability of the final product. By reducing the cost of PCB assembly production, a company can increase its profit margin, maintain competitiveness in the market, and invest resources into research and development of new products. Additionally, cost-saving measures can improve overall manufacturing efficiency, reduce defects and production errors, and enhance the quality of the end product. Therefore, an emphasis on cost-saving in PCB assembly production is essential for long-term business success.

Conclusion

Maintaining a long-term partnership with a single PCB assembler or manufacturer is advantageous for your company. Engaging in trial and error with products from different manufacturers cannot produce consistent results. It is therefore important to foster strong mutual cooperation and trust with your PCB assembler to achieve greater goals and generate more business. This, in turn, may result in lower pricing for your orders.

It is crucial to keep in mind that the cost of PCBA for an electrical device project is just a small portion of the overall expense. While prices may vary based on the supplier and location, they are not the primary factor driving up costs.

Related Posts:

- Mixed PCB Assembly Technology Services For Your Next New Project

- Why Electronic Potting is So Important in PCB Assembly?

- A Full Guide to Electro mechanical Assemblies

- Cable and Wire Harness Assembly

- Electronics Components PCB Assembly

- China:The Best PCB Consignment Assembly Services At JarnisTech

- PCB Box Build Assembly

- What Is Printed Circuit Boards Assembly?

- How Many Types of Turnkey PCB Assembly?