At JarnisTech, we take great pride in our exceptional ability to manufacture high-quality electronic components with a near-zero attrition rate. Our IC products boast an attrition rate of 0%, while our Capacitor and Resistor components have a rate of just 0.3%. Our precision assembly techniques enable us to produce incredibly accurate chips, including 03015 chip/0.35 pitch BGA.

We understand that the key to providing our customers with the lowest possible manufacturing costs lies in the procurement of low-cost components. To achieve this, we have a dedicated sourcing team that utilizes reliable channels to obtain components at the lowest prices available in the global market, even for those that are typically hard to find.

Our extensive range of products includes active component assemblies such as IC integrated circuits, memory chips, diodes, transistors, as well as passive components like capacitors, resistors, inductors, and electromechanical components such as connectors and switching devices. We also specialize in sourcing other hard-to-find special electronic components.

At JarnisTech, we are committed to providing our customers with the highest quality products at the most competitive prices. We achieve this by utilizing our expertise in precision assembly techniques and reliable sourcing channels to deliver exceptional electronic components that meet the needs of a wide range of industries and applications.

Electronics Assembly Components

In the realm of electronics, a printed circuit board (PCB) can be likened to a living organism with each component serving as a vital organ. The copper traces of the PCB can be considered the skeleton, providing essential structural support. Each electronic component plays a unique role in imparting the circuit with the specific qualities necessary to perform its intended function. Depending on the type of electronic equipment or device for which the bare PCB circuit board is designed, a range of diverse components may be required for various circuits.

Some of the most commonly used electronic components in PCB assembly include:

Battery – an indispensable component that acts as the voltage or current source for the circuit. Without it, the PCB cannot function unless directly connected to a DC source.

Resistors – a form of amplifier used to switch or control the electronic signals within the board. While transistors come in various types, the most common is the bipolar transistor, which has three pins: the collector, base, and emitter.

Inductors – similar in nature to capacitors, these components store energy as a magnetic field when current flows through them. Inductors are primarily used to block unwanted signals in a PCB board, such as interference from other electronic devices or equipment.

Capacitors – second in popularity only to resistors, capacitors hold an electrical charge in the circuit board and release it when extra power is needed elsewhere. This is achieved by the two conductive layers of the capacitor holding opposite charges, separated by an insulating material.

Diodes – miniature devices within a circuit responsible for allowing the unidirectional flow of electrical current. Diodes are used to stop or block current flow in an unwanted direction and can include popular examples such as LEDs used for emitting light.

Transformers – essential components used to transfer electrical energy from one circuit to another by increasing or decreasing the voltage.

Sensors – critical electronic components that detect environmental changes and generate corresponding electrical signals. These signals are then sent to other circuit components. Sensors convert physical elements such as air quality, light, motion, or sound into electrical energy.

At the heart of any PCB is the careful selection and integration of high-quality electronic components. These components work together to create a functional and reliable circuit board that meets the specific needs of the intended application.

How Does PCB Electronics Components Assembly Work?

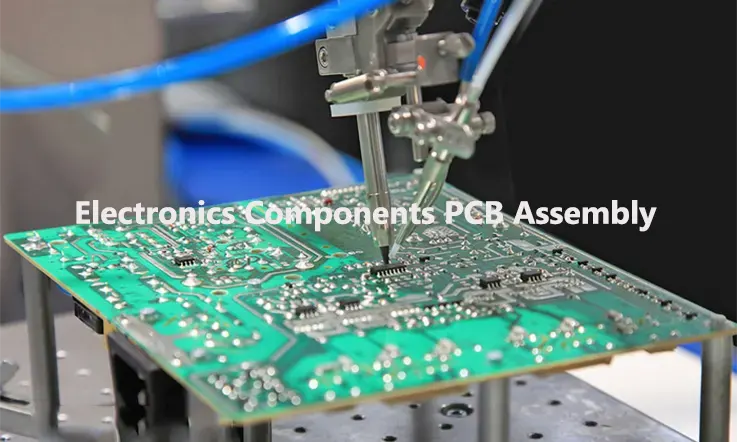

PCB assembly (PCBA) is a process of assembling electronic components onto a printed circuit board (PCB) to create a functional electronic device. The following are the steps involved in PCBA components assembly:

1. Solder Paste Application: Solder paste is applied to the PCB using a stencil. The stencil ensures that the solder paste is applied only to the correct locations on the PCB.

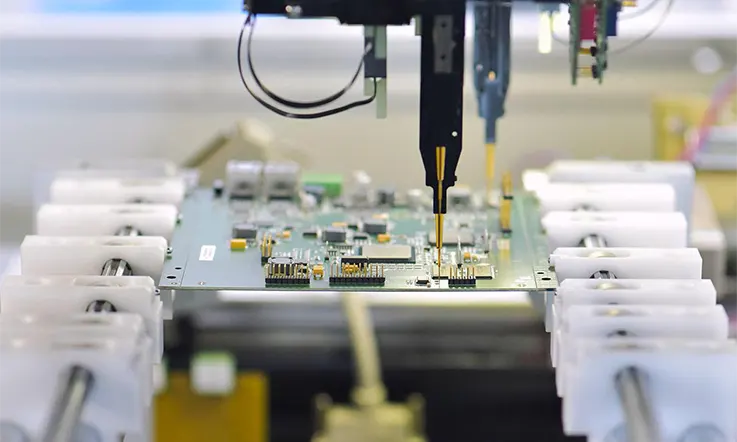

2. Component Placement: The components are placed onto the PCB using automated equipment. This is done by using pick-and-place machines that take the components from their reels and place them onto the PCB.

3. Reflow Soldering: Once the components are placed onto the PCB, the board is heated in a reflow oven. The oven melts the solder paste, which then creates a permanent bond between the components and the PCB.

4. Inspection: After the reflow soldering process, the PCB is inspected to ensure that all components are properly placed and soldered. The inspection can be done manually or using automated inspection equipment.

5. Testing: Once the inspection is complete, the PCB is tested to ensure that it functions as intended. Various tests such as functional testing, in-circuit testing, and boundary scan testing are performed to check the functionality of the PCB.

6. Final Assembly: Once the PCB has passed all the tests, it is assembled into the final product. This can involve adding additional components, enclosures, and packaging.

Overall, PCBA components assembly is a complex process that requires specialized equipment and expertise. It is an essential step in the manufacturing of electronic devices.

Type of Electronic PCB Assembly

There are several different types of electronic PCB assembly, including:

Through-Hole Assembly

This is the traditional method of PCB assembly, where components are inserted into pre-drilled holes on the PCB and then soldered onto the board.

Surface Mount Technology (SMT) Assembly

This method involves mounting components directly onto the surface of the PCB without the need for pre-drilled holes. SMT components are much smaller and can be placed closer together, allowing for more compact designs.

Mixed Technology Assembly

This involves using both through-hole and SMT components on the same PCB. This method is often used when a PCB requires both large components that need to be through-hole mounted and small components that need to be SMT mounted.

Ball Grid Array (BGA) Assembly

This method is used for mounting components that have a large number of pins, such as microprocessors and memory chips. BGA components have a grid of small solder balls on the underside that are used to make contact with the PCB.

Package-on-Package (PoP) Assembly

This method involves stacking one or more components on top of another component, allowing for more components to be mounted in a smaller space.

Chip-on-Board (CoB) Assembly

This method involves mounting bare semiconductor chips directly onto the PCB. This method is often used in applications where size and weight are critical factors.

Each of these assembly methods has its advantages and disadvantages, and the most appropriate method will depend on the specific requirements of the PCB and the final product.

How to Find the Right Electronics Component PCB Assembly Maker?

Finding the right electronics component PCB assembly maker can be a daunting task, but there are a few steps you can take to ensure that you choose the right company for your needs. Here are some suggestions:

Look for experience and expertise

Check the company’s website and look for information about their experience in the industry, their areas of expertise, and the types of projects they have worked on. A company with experience and expertise will be able to provide you with high-quality PCB assembly services.

Check the company’s certifications

Look for companies that have certifications such as ISO 9001:2015, IPC-A-610, and J-STD-001. These certifications indicate that the company follows industry standards and best practices.

Consider the company’s equipment and technology

Check the company’s equipment and technology to ensure that they are up-to-date and can handle your project’s requirements. A company with advanced equipment and technology will be able to provide you with high-quality PCB assembly services.

Check the company’s customer service

Communication is crucial in the PCB assembly process, so it’s important to choose a company with excellent customer service. Look for a company that is responsive, communicative, and willing to work with you to meet your needs.

Ask for references and reviews

Don’t be afraid to ask the company for references or reviews from previous customers. This can help you gauge their reputation and the quality of their work.

Compare quotes

Finally, get quotes from multiple companies and compare their prices, services, and capabilities. This will help you choose the best option for your project’s needs and budget.

By following these steps, you can find the right electronics component PCB assembly maker for your project.

Why Choose Us?

Advantages of JarnisTech in electronics Components PCB Assembly:

Our supply chain guarantee is one of our key advantages

We work closely with well-known brand manufacturers and agents to ensure that our customers receive only original and new products, free of fake and substandard items. Our professional IQC team conducts strict inspections on every part to guarantee that each product is genuine, and we offer our customers the most competitive prices for PCB and PCB assembly.

We offer a comprehensive range of products, including integrated circuits (ICs), MOS field-effect transistors, diodes, Schottky, voltage regulators, silicon-controlled rectifiers, optical couplers, IGBT/power tube patch LED, capacitors, resistors, inductors, connectors, and more. Our wide channels and international collaborations with leading brands enable us to provide the highest quality products to our customers.

Fast Delivery is Another of Our key Advantages

We have established stable channels and hold a large amount of inventory to ensure rapid delivery of components. Our supply of conventional components is consistent, and we guarantee that there are no order delays.

We practice full supply chain management and purchase only from franchisees or directly from component manufacturers to ensure full traceability. This allows us to obtain the best opportunities and price points while ensuring that all suppliers are trustworthy and reliable, and that the procurement process is fully traceable.

With our many years of distribution and inspection experience, we provide our customers with the most reliable products and services. Our professional team is quick to respond to inquiries and orders, and they have a wealth of experience and understanding of market trends, enabling us to provide cost-effective services to our customers. Customers can provide us with individual product information or a full BOM, and we will provide them with a product quotation and delivery time as soon as possible.

JarnisTech: Quality & Professional Service You Can Trust

At Jarnistech, we understand that quality is crucial in PCB production. That’s why we are committed to ensuring that our customers receive the best possible final quality PCBs. All of our manufacturing facilities are ISO 9001 certified, and we regularly update our equipment to meet our customers’ PCB requirements.

Our dedication to quality has earned us a growing customer base, with over 150 new customers registering with us every day. Many of these customers come to us through referrals from our satisfied customers. Our quality control engineers conduct routine inspections of PCBs during production and before shipment to ensure that they meet our high standards. In addition to visual checks, we use appropriate testing machines to test 100% of the boards.

Quality is the cornerstone of our business, and we understand that the PCB business requires the involvement of professional engineers to clarify technical specifications and troubleshoot technical problems with our customers. Our engineers are trained professionals who provide a free engineering file review service to check your orders before transferring them to fabrication sections to minimize errors.

Our engineers are also skilled businessmen who know how to save costs for our customers while maintaining high-quality standards. We guarantee that all shipped PCBs are compliant with your requests, and we conduct a thorough quality check before shipment to ensure that our customers receive the best possible product.

At Jarnistech, we are committed to providing our customers with the highest quality PCBs and exceptional customer service. We believe that our dedication to quality is the main factor in our growing reputation and word-of-mouth referrals, which help us to expand our business globally.

Common Issues in Electronics Components and PCB Assembly

There are several common issues that can occur in electronics components and PCB assembly. These issues can affect the performance and reliability of the system or device, and may require troubleshooting and repair to resolve. Here are some examples:

Component Issues: Faulty or damaged components can cause a range of problems, such as incorrect operation, intermittent faults, or complete failure. This can be caused by manufacturing defects, damage during shipping or handling, or issues with the component’s design or specifications.

Soldering Issues: Poor soldering can cause issues such as cold joints, solder bridges, or insufficient solder. This can result in intermittent faults, poor connectivity, or complete failure. Soldering issues can be caused by incorrect soldering techniques, poor quality solder, or issues with the PCB design or layout.

PCB Layout Issues: PCB layout can have a significant impact on the performance and reliability of a system or device. Poor layout can cause issues such as noise, crosstalk, or signal integrity problems. This can be caused by issues with the design or layout software, incorrect component placement, or poor routing.

Environmental Issues: Environmental factors such as temperature, humidity, and vibration can affect the performance and reliability of electronics components and PCBs. This can cause issues such as corrosion, thermal stress, or mechanical failure.

Power Supply Issues: Power supply issues such as overvoltage, undervoltage, or noise can cause a range of problems in electronics components and PCBs. This can affect the operation of the system or device, and may cause damage to components or the PCB itself.

Firmware and Software Issues: Issues with firmware or software can cause a range of problems, such as incorrect operation, crashes, or system failures. This can be caused by bugs in the software, incorrect configuration, or issues with the hardware or firmware.

In summary, common issues in electronics components and PCB assembly can include component issues, soldering issues, PCB layout issues, environmental issues, power supply issues, and firmware and software issues. Identifying and resolving these issues can require a combination of technical knowledge, analytical skills, and experience, as well as the ability to think creatively and outside the box to find solutions to complex problems.

Repair Techniques for Component Assemblies

Repair techniques for component assemblies can vary depending on the nature of the issue and the specific components involved, but here are some common techniques that may be used:

Component Replacement: If a faulty component is identified, it may need to be replaced. This can involve removing the faulty component and installing a new one in its place. Component replacement may require special tools and techniques, such as desoldering tools, heat guns, or specialized pliers.

Soldering and Desoldering Techniques: Soldering and desoldering techniques are used to remove and replace components and to make repairs to solder joints. These techniques can include using a soldering iron, a hot air gun, or a reflow oven. Proper soldering and desoldering techniques are critical to ensure a reliable repair.

PCB Repair and Modification: PCB repair and modification can involve repairing damaged traces or pads, adding or removing components, or modifying the layout of the PCB to improve performance or correct issues. PCB repair and modification may require specialized tools and techniques, such as conductive paint, epoxy, or a PCB milling machine.

Firmware and Software Updates: In some cases, issues with component assemblies may be caused by bugs or issues with the firmware or software. Updating the firmware or software can sometimes resolve these issues. This may involve downloading and installing updates from the manufacturer’s website or using specialized software tools to flash the firmware.

Repair Tips and Tricks: Depending on the specific issue and the components involved, there may be some specialized repair techniques or tricks that can be used to resolve the issue. These can include using specialized tools or equipment, adjusting settings or parameters, or making modifications to the system or device to improve performance or correct issues.

All in all, repair techniques for component assemblies can include component replacement, soldering and desoldering techniques, PCB repair and modification, firmware and software updates, and specialized repair tips and tricks. Proper repair techniques are critical to ensure a reliable repair and to prevent further issues from occurring.

Final Thoughts

PCB components assembly is a critical process in the production of electronic devices. It involves the mounting of various electronic components onto a printed circuit board using automated equipment and then soldering them into place. The components used in PCB assembly can include passive and active devices, as well as connectors and switches.

The assembly process can involve surface mount technology, through-hole assembly, or a combination of both. Testing and inspection are also important steps in the process to ensure that the assembled board is functional and reliable. As technology advances, the future of PCB assembly is likely to involve even more automation and precision, further improving the quality and efficiency of electronic device production.

Related Posts:

- Mixed PCB Assembly Technology Services For Your Next New Project

- Why Electronic Potting is So Important in PCB Assembly?

- A Full Guide to Electro mechanical Assemblies

- Cable and Wire Harness Assembly

- What Is Printed Circuit Boards Assembly?

- China:The Best PCB Consignment Assembly Services At JarnisTech

- PCB Box Build Assembly

- Nine Method of Save Cost PCB Assembly Production

- How Many Types of Turnkey PCB Assembly?