As a design engineer or product manager, you’re constantly navigating a tough landscape. The demand is for smaller, more powerful, and more efficient electronics. Yet, with greater power density comes a familiar adversary: heat. Unmanaged, it can undermine performance, shorten a product’s lifespan, and compromise reliability. All of this is compounded by the growing need to meet stringent global environmental standards.

The Shengyi SAR15 aluminum-based substrate is a material engineered to address these requirements directly. It provides a robust foundation for heat-sensitive electronics by integrating thermal dissipation into the structure of the board itself. This document serves as a technical guide to the SAR15 material, offering engineering insights into its application, design considerations, and the manufacturing discipline required to translate its potential into a finished, dependable product.

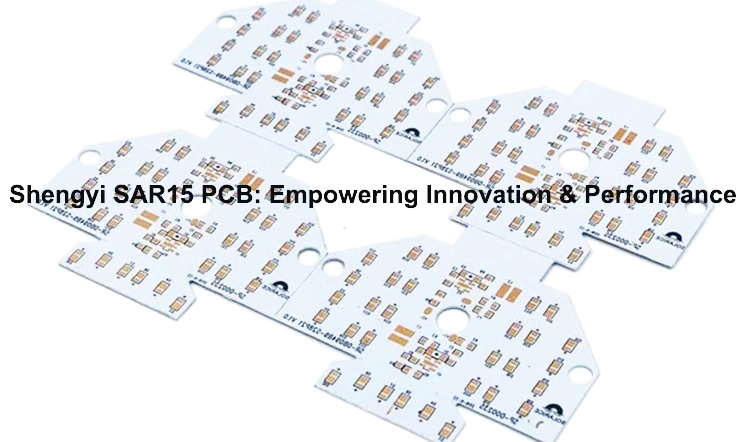

Shengyi SAR15 PCB: A Guide to Halogen-Free Thermal Management

For design engineers and product developers, managing heat while meeting strict environmental regulations is a persistent challenge. The Shengyi SAR15 aluminum-based PCB directly addresses these needs, offering a reliable foundation for electronics requiring dependable performance when heat is a factor. It combines effective heat dissipation with a halogen-free composition, making it a forward-looking choice for demanding applications.

This guide outlines the technical profile of SAR15, its practical advantages for modern electronic design, and the specific industries where it is currently being deployed with success.

Technical Profile: What is Shengyi SAR15?

Shengyi SAR15 is an engineered laminate designed to move heat away from active components far more efficiently than standard FR-4 substrates. This characteristic is fundamental to improving product reliability and extending operational life, particularly in compact designs where airflow is limited.

Core Specifications:

●Aluminum Core: Provides a solid, thermally conductive base for rapid heat transfer away from sensitive components.

●Halogen-Free Composition: Ensures compliance with global environmental standards, including RoHS and REACH, making it suitable for products sold worldwide.

●Thermal Conductivity: Features a dielectric layer with a thermal conductivity of approximately 1.5 W/m·K for effective heat transfer.

●Dielectric Strength: Offers a breakdown voltage greater than 5 kV, supporting robust power applications.

●Flame Resistance: Carries a UL94V-0 rating, meeting safety requirements for flammability.

What Are the Advantages of an Aluminum, Halogen-Free Substrate?

Opting for a material like SAR15 brings distinct benefits to the design and manufacturing process, moving beyond simple specifications to offer tangible improvements.

●Superior Thermal Performance: The aluminum base functions as an integrated heat spreader. This construction actively prevents the formation of localized hot spots on the board, which are a common cause of performance throttling and premature component failure.

●Greater Design Freedom: By efficiently managing heat at the board level, SAR15 can reduce or even eliminate the need for bulky, external heatsinks and cooling fans. This allows for more compact, lightweight, and streamlined product designs.

●Built-in Regulatory Compliance: For companies operating in or exporting to markets with stringent environmental laws, using a halogen-free material is a straightforward way to meet compliance. It simplifies the supply chain and minimizes end-of-life disposal concerns.

Primary Applications and Industries

The functional benefits of SAR15 make it a versatile material used across a range of technology sectors.

LED Lighting:

In high-intensity LED applications, from architectural lighting to automotive headlamps, SAR15 allows LEDs to deliver their true brightness and color temperature without thermal degradation by keeping junction temperatures low. Additionally, its white solder mask option helps maximize light reflectivity.

Automotive Electronics:

The material’s durability against thermal cycling and vibration makes it a fit for on-board systems like battery management systems (BMS), DC-DC converters, and engine control units (ECUs).

Consumer Electronics:

In the pursuit of smaller, more powerful devices, SAR15 manages heat in compact power adapters, miniaturized chargers, and smart home devices, enabling fanless and silent operation.

Industrial Systems:

For power supplies, motor drives, and control relays that operate continuously in demanding environments, SAR15 provides the operational stability needed for long-term, dependable service.

Core Material Properties of the Shengyi SAR15 PCB

The Shengyi SAR15 PCB is engineered to provide a stable and dependable substrate for applications where heat management and electrical insulation are a priority. Its material composition is finely tuned to support products across their entire lifecycle, from high-output LED modules to power converters in automotive and industrial settings.

Understanding the specific characteristics of SAR15 allows engineers and procurement specialists to confidently match the material to their design requirements. Below, we detail the properties that define its performance under thermal, electrical, and mechanical stress.

Thermal, Safety, and Insulation Properties

The combination of thermal performance and safety ratings in SAR15 makes it a well-rounded choice for modern electronics.

Thermal Conductivity:

With a rating of approximately 1.5 W/m·K, the material efficiently channels heat away from active components. The aluminum base further aids in spreading this thermal energy, reducing localized hot spots and making it ideal for designs that rely on passive cooling.

Flame Retardancy:

SAR15 meets the UL94V-0 standard. This rating confirms that the material will self-extinguish upon exposure to flame, a necessary feature for electronics housed in enclosed spaces.

Comparative Tracking Index (CTI):

The CTI value exceeds 600V, indicating a high resistance to the formation of conductive paths along the board’s surface. This provides a greater margin of safety in humid environments or where surface contamination is a possibility.

| Property | SAR15 Typical Value | Standard or Test Method |

| Thermal Conductivity | 1.5 W/m·K | ASTM D5470 |

| Flame Retardancy | UL94V-0 | UL 94 |

| CTI (Comparative Tracking Index) | >600V | IEC 60112 |

Dielectric and Electrical Strength

SAR15 is designed to maintain electrical integrity, ensuring signals and power are routed reliably.

●Dielectric Constant: The material’s stable dielectric constant ensures reliable signal performance in analog driver circuits and other frequency-sensitive applications. This stability enables designers to accurately model and manage signal integrity.

●Dielectric Breakdown: SAR15 exhibits a dielectric breakdown voltage typically above 5kV. This high electrical strength securely isolates power planes and ground, permitting tighter and more compact circuit layouts.

●Insulation Resistance: The substrate maintains high insulation resistance even after exposure to humidity or thermal shock, contributing to the long-term reliability of the final product in variable field conditions.

| Electrical Property | Typical Value | Test Method |

| Dielectric Constant (1 MHz) | 4.5 – 5.0 | ASTM D150 |

| Dielectric Breakdown Voltage | >5000V | ASTM D149 |

| Insulation Resistance (after humidity) | >10⁸ Ω | IPC-TM-650 Method 2.6.3.2 |

Mechanical Structure and Layer Configuration

The mechanical foundation of SAR15 ensures board-level stability during both assembly and operation.

●Robust Foundation: The aluminum core provides exceptional rigidity, resisting warping during reflow soldering processes. In high-vibration environments like motor controllers or battery systems, this stiffness enhances long-term durability.

●Configuration Flexibility: While commonly used in single-layer aluminum PCBs, SAR15 can be adapted for two-layer designs with appropriate stack-up planning.

●Machinability: The material allows for precise mechanical processing such as routing, V-cutting, and punching. Its uniform thickness and low Z-axis expansion contribute to outstanding dimensional stability, providing a flat and dependable surface for component mounting.

| Mechanical Feature | Specification / Performance | Notes |

| Aluminum Base Thickness | 1.0 mm typical (customizable) | Tolerance ±10% |

| Flexural Strength | ≥100 MPa | ISO 178 |

| Z-Axis Thermal Expansion | Low | Reduces delamination risks |

| Machinability | Excellent | Suitable for routing, drilling, punching |

| Typical Layer Configuration | Single or Double Layer | Depending on thermal path design |

Design and Manufacturing Considerations for Shengyi SAR15

Effective design with Shengyi SAR15 laminates requires attention to thermal pathways, electrical integrity, and mechanical constraints. To help engineers and designers achieve thermally stable and reliable layouts, this section outlines practical strategies for component placement, via design, and manufacturability that are field-tested for aluminum-based PCBs. Adopting these practices can lead to improved performance and smoother production cycles.

Layout Strategies for Thermal Control

For high-brightness LEDs, power regulators, and other heat-generating components, the board layout is the first line of defense against thermal overload. While the SAR15 aluminum core is effective at spreading heat, its performance is maximized through careful design.

To manage temperature effectively:

●Align Thermal Pads: Directly match the component’s thermal pad with an exposed copper area on the PCB to create the shortest possible heat path.

●Apply TIM Correctly: Use a suitable thermal interface material (TIM) between the component and the board to fill microscopic air gaps and ensure an uninterrupted heat flow.

●Space Components Evenly: Distribute high-power components across the board to prevent localized heat buildup and thermal shadowing.

●Maintain Layout Symmetry:For LED modules, a symmetrical component layout helps maintain uniform temperature gradients, leading to steady luminous output and stable color performance.

Recommendations for Vias and Copper Layers

While many SAR15 applications are single-layer, vias and copper thickness become main factors in more complex or high-current designs.

Guidelines for vias and copper:

●Use Thermal Vias When Needed: In double-layer designs, place an array of plated thermal vias directly under power components to effectively channel heat to the aluminum core or adjacent copper planes.

●Select Appropriate Copper Thickness: Use copper weights from 1oz to 3oz (35µm to 105µm), balancing the current-carrying requirements with the need for fine-pitch etching precision.

●Ensure Adequate Annular Ring Size: Maintain sufficient annular ring dimensions around vias to guarantee a solid connection, especially in designs mixing power and signal traces.

●Manage Via Aspect Ratio: For higher reliability, aim for a via aspect ratio below 8:1. This enhances the uniformity of the plating process and strengthens the mechanical integrity of the via structure.

| Element | Specification | Purpose/Consideration |

| Copper Thickness Options | 1 oz (35 µm), 2 oz (70 µm), 3 oz (105 µm) | Balance between current capacity and etching resolution |

| Thermal Vias | Via array: Ø 0.3–0.5 mm, spacing ≤1.0 mm | Transfers localized heat to aluminum or inner layers |

| Annular Ring | ≥ 0.15 mm | Ensures plating consistency and mechanical reliability |

| Via Aspect Ratio | ≤ 8:1 (e.g., 0.3 mm dia / 2.4 mm depth max) | Ensures plating quality and reduces via cracking |

| Via Fill (Optional) | Filled or tented (especially under thermal pads) | Improves heat transfer and prevents solder wicking |

DFM Guidelines for Aluminum PCBs

Design for Manufacturability (DFM) focuses on ensuring your layout matches practical production capabilities. Aluminum substrates like SAR15 demand different machining approaches compared to standard FR-4.

To improve manufacturability:

●Use Smooth Corner Radii: Avoid sharp internal angles in board cutouts. Gradual, rounded corners reduce mechanical stress on the aluminum and minimize tooling wear during routing.

●Maintain Copper-to-Edge Spacing: Keep a generous clearance between copper features and the board edge to prevent shorting or delamination during V-scoring, routing, or milling operations.

●Include Clear Manufacturing Marks: Standardize tooling holes and add clear fiducial marks to your design to ensure accurate alignment and registration during automated assembly.

●Consider Solder Mask and Thermal Ramps: Choose a solder mask capable of enduring the rapid thermal cycles of assembly. Since SAR15 dissipates heat efficiently, it’s important to account for fast temperature ramps during reflow to ensure reliable soldering, particularly for fine-pitch components.

Ensuring Quality: Our Manufacturing Process for Shengyi SAR15 PCBs

Producing reliable Shengyi SAR15 aluminum PCBs requires specialized processes that go far beyond standard fabrication. Our approach, refined over two decades of aluminum PCB production, is built to address the unique properties of SAR15’s thermally conductive dielectric and its metal base. By carefully controlling every stage, we ensure the final product meets the demanding functional and aesthetic requirements of the LED lighting, industrial automation, and power electronics markets.

Laminate Preparation and Precision Drilling

The foundation of a reliable SAR15 board begins with how the raw material is handled and machined. Our process starts with meticulous preparation to preserve the integrity of the laminate.

●Careful Material Handling: We begin with precise cutting and cleaning of the SAR15 laminate, using protocols that prevent surface contamination or stress fractures in the heat-conductive dielectric layer.

●Specialized Drill Management: Drilling into SAR15’s composite structure causes faster tool wear than with FR-4. We closely monitor drill life and adjust parameters to maintain hole quality, which is fundamental for uniform plating in double-layer designs.

●Optimized CNC Machining: To prevent burrs and delamination, our CNC drilling and routing parameters—including speeds, feeds, and coolant selection—are specifically calibrated for the hardness and thickness of the SAR15 material.

Selecting the Right Surface Finish

The choice of surface finish directly impacts solderability, durability, and in some cases, the performance of the final product. We guide clients to the most suitable option based on their application.

●ENIG (Electroless Nickel Immersion Gold): Recommended for its flat, durable, and oxidation-resistant surface. It is ideal for fine-pitch components and offers a long shelf life.

●HASL (Hot Air Solder Leveling): A cost-effective solution, but the uneven surface it can create makes it less suitable for applications requiring high-precision component placement, such as in LED optical assemblies.

●OSP (Organic Solderability Preservative): A lead-free, cost-efficient option that provides a flat surface. Its lower durability makes it best for controlled assembly environments with minimal storage time.

●White Solder Mask: Frequently used for LED applications made with SAR15. This finish not only protects the circuitry but also enhances light reflectivity, contributing to the overall efficiency of the lighting module.

Managing Warpage, Solderability, and Production Tolerances

Maintaining tight control over the board’s physical characteristics supports reliable performance and smooth integration into automated assembly lines.

●Warpage Control: Aluminum substrates react to thermal cycling. Our production flow incorporates controlled pre-baking and handling procedures to minimize board deformation and ensure flatness after reflow soldering.

●Solderability Assurance: We ensure reliable solder wetting through stringent control of surface cleanliness and texture. For high-power designs, we can advise on copper pad modifications to support larger solder fillets for improved thermal coupling.

●Tight Mechanical Tolerances: We maintain narrow margins on all mechanical features, including hole-to-edge clearance, routing accuracy, and solder mask alignment, to meet the strict requirements of dense layouts and automotive-grade modules.

Quality and Reliability: How We Validate Shengyi SAR15 PCBs

A material’s datasheet sets performance expectations; thorough testing provides the evidence. Before any Shengyi SAR15 board leaves our facility, we validate its physical and thermal properties to confirm it can endure real-world conditions. In applications such as automotive lighting or industrial power supplies, this level of quality control supports stable and repeatable performance. This section details the evaluation methods we use to ensure every SAR15 board is built for long-term reliability.

Thermal Stress and Longevity Testing

We verify the board’s endurance against the primary stressor in its intended applications: heat.

1. Thermal Cycling:

Boards are subjected to repeated temperature transitions, simulating years of power-up and power-down cycles. This test validates the integrity of the material interfaces, ensuring the board resists delamination or material fatigue.

2. Accelerated Aging:

To assess long-term stability, we expose boards to sustained high-temperature and high-humidity conditions (e.g., up to 1,000 hours). This process confirms that the material retains its insulation resistance and mechanical strength over its expected service life.

Verification of Safety and Environmental Ratings

Our process includes checks to ensure that the boards conform to established safety and environmental resilience standards.

●UL94V-0 Flame Retardancy: We confirm the material’s compliance with this standard, verifying its resistance to ignition and its ability to self-extinguish. This is a baseline safety requirement for components used in enclosed or heat-sensitive products.

●Comparative Tracking Index (CTI): The high CTI rating of SAR15 is verified to confirm its resistance to electrical tracking caused by surface moisture or contamination, offering a wider safety margin in diverse operating environments.

●Moisture Resistance: Through tests like 85°C/85% RH storage, we validate SAR15’s capacity to maintain stable insulation performance even in damp or humid conditions, making it suitable for sealed enclosures or outdoor installations.

Mechanical and Electrical Integrity Tests

We conduct tests to quantify the board’s physical robustness and electrical insulation capabilities.

| Test Method | Purpose | SAR15 Typical Result |

| Peel Strength | Measures adhesion of copper to substrate | ≥1.8 N/mm (after thermal aging) |

| Dielectric Strength | High-voltage applied across insulation layer | ≥5 kV/mm |

| Thermal Resistance (Rth) | Assesses heat dissipation through the dielectric | ≤1.0°C·cm²/W (depending on thickness) |

| Warpage/Flatness | Board planarity across 100 mm span | ≤0.75% (IPC standard compliant) |

●Peel Strength: This test measures the adhesion strength between the copper foil and the dielectric layer. Verifying a high peel strength ensures the copper traces will remain securely bonded through soldering, rework, and operational stress.

●Dielectric Strength: We validate the insulation layer’s ability to withstand high voltage without breakdown. This confirms the board can safely handle its specified electrical load with a reliable margin.

●Thermal Resistance: This metric is assessed to confirm how efficiently heat moves from a component through the board to the aluminum base. A low thermal resistance value is a direct indicator of superior thermal performance.

A Comparison of Shengyi SAR15, SAR10S, SAR20, and FR-4

Choosing the appropriate PCB substrate requires weighing performance, thermal demands, and budget. Traditional FR-4 is often used for low-power applications, but Shengyi’s aluminum-based SAR series stands out for its thermal handling capabilities. Recognizing the distinctions between these materials allows you to match your design with a more suitable and effective base.

This comparison breaks down the profile of each material to clarify where Shengyi SAR15 fits and why it is often the preferred choice for modern electronics.

1.FR-4 (The Conventional Standard)

●Thermal Performance: Very low thermal conductivity (typically under 0.3 W/m·K). Not suitable for applications where heat dissipation is a design consideration.

●Cost Position: Generally the lowest-cost option for base material.

●Environmental: May contain brominated flame retardants, which can pose challenges for products requiring strict halogen-free compliance.

●Best For: Low-power, low-cost applications with no significant thermal load.

2.Shengyi SAR10S (The Economical Aluminum Choice)

●Thermal Performance: Offers improved thermal conductivity over FR-4 (around 1.0 W/m·K).

●Cost Position: An economical entry into aluminum-based PCBs for cost-sensitive projects.

●Environmental: Fully halogen-free and RoHS compliant.

●Best For: Cost-sensitive designs like consumer lighting or entry-level power supplies that need better thermal performance than FR-4 but operate under modest thermal loads.

3.Shengyi SAR15 (The Balanced, High-Performance Solution)

●Thermal Performance: Excellent thermal conductivity at approximately 1.5 W/m·K, providing a significant upgrade over SAR10S and FR-4.

●Cost Position: A mid-range option that provides a superior performance-to-cost ratio. It avoids the premium expense of higher-end substrates while delivering robust thermal handling.

●Environmental: Fully halogen-free and RoHS compliant, aligning with modern green manufacturing directives.

●Best For: A wide range of applications, including high-performance LED lighting, automotive electronics, and industrial power modules, where reliable heat dissipation and dependable operation are required.

4.Shengyi SAR20 (The Premium Thermal Solution)

●Thermal Performance: The highest thermal conductivity in this group (often exceeding 2.0 W/m·K).

●Cost Position: A premium substrate for designs where performance cannot be compromised.

●Environmental: Fully halogen-free and RoHS compliant.

●Best For: Power-intensive applications with high component density, such as high-output LED floodlights, advanced motor control units, or high-power DC-DC converters.

Summary Comparison Table

| Material | Thermal Conductivity (W/m·K) | Halogen-Free | Flame Retardant | Typical Use Case |

| FR-4 | < 0.3 | No | Yes (with BFRs) | Basic electronics |

| SAR10S | ~1.0 | Yes | Yes | Consumer LEDs, budget circuits |

| SAR15 | ~1.5 | Yes | Yes | Industrial LEDs, automotive |

| SAR20 | >2.0 | Yes | Yes | High power, dense applications |

Why Partner with JarnisTech for Your Shengyi SAR15 PCBs?

The success of a project using Shengyi SAR15 substrates relies on both the quality of the material and the expertise of the manufacturer. At JarnisTech, we blend advanced fabrication techniques with extensive engineering experience to deliver dependable, high-quality aluminum PCBs for our global clients in consumer electronics, LED lighting, and industrial automation. Our production and communication processes are structured to meet the speed and accuracy your projects require.

Certified Quality and Compliance

Certifications are more than just documents; they are proof of a disciplined manufacturing process you can trust. Our globally recognized certifications confirm product safety and process stability, giving you confidence in every board.

●ISO 9001 Certified Quality Management: Our fabrication processes operate under a certified ISO 9001 system, ensuring consistent quality, process control, and full traceability from start to finish.

●UL Recognized Components: All our SAR15 boards meet UL 94V-0 flame retardancy standards. Using UL-recognized components from us simplifies your own end-product safety certification process.

●RoHS and Halogen-Free Compliance: We provide full documentation confirming our materials meet RoHS standards and halogen-free regulations, helping to reduce your environmental audit risks and support adherence to modern product lifecycle guidelines.

Advanced Capabilities for Custom Designs

While SAR15 is often used in single-layer designs, our capabilities allow for advanced customization to meet unique layout and performance requirements. We work closely with engineering teams to develop the ideal stack-up and finish for each application.

Our capabilities include:

●Specialized Solder Masks: High-reflectance white solder mask for LED modules and other options with stable heat resistance.

●Versatile Surface Finishes: OSP, ENIG, and HASL finishes, all adapted and optimized for use on aluminum-backed boards.

●Customized Layer Construction: Controlled prepreg thickness and copper weights tailored to your specific thermal and electrical needs.

●Hybrid Stack-Up Designs: The ability to combine FR-4 and aluminum materials in a single, rigid board for designs requiring isolated sections.

| Customization Option | Description | Use Case/Application |

| White Solder Mask (High Reflectance) | Enhanced visibility and light output for LED boards | LED lighting modules, smart bulbs |

| Surface Finish Options | ENIG, HASL, OSP, immersion silver & tin | Power supplies, automotive modules |

| Copper Thickness Range | 0.5 oz to 3 oz (17μm–105μm) available for thermal design tuning | High-power drivers, DC-DC converters |

| Hybrid Structure Integration | FR-4 + aluminum mixed stack-up options | Multi-zone thermal control circuits |

| Prepreg Control | Dielectric thickness ±10% for impedance-sensitive designs | Signal conditioning circuits, analog sensors |

A Collaborative Approach to Manufacturing

We believe the best results come from partnership, not just transactions. Manufacturing aluminum PCBs presents unique challenges, and we encourage early communication to ensure a smooth process from design to delivery.

Here are some practices that foster successful collaboration:

●Share Gerber files with detailed layer notes, specifying requirements like copper weight and aluminum thickness.

●Confirm the required surface finish early in the process to align with the application and material capabilities.

●Discuss stencil design and thermal pad requirements, especially for high-power LED or IC mounting.

●Align on panelization strategies and shipping tolerances to ensure compatibility with your assembly lines.

Our team acts as an extension of yours, helping you navigate thermal management questions, panelization, and material specifications. This deep familiarity with Shengyi SAR15’s characteristics helps our clients avoid late-stage surprises and move from design to production with confidence.

Take the Next Step with JarnisTech

When your project demands stable thermal performance and halogen-free compliance, having access to full technical data and transparent engineering support makes all the difference. At JarnisTech, we provide the resources and responsive communication your team needs to move from design to production without delay.

Here’s how you can get started:

Download the SAR15 Technical Data Package

For detailed material specifications, we offer direct access to the complete Shengyi SAR15 Technical Data Sheet (TDS), along with UL listing details and RoHS/halogen-free declarations. These documents include our own production compatibility notes on copper weight, thermal resistance, and mechanical tolerances.

To receive the full datasheet package, simply contact us through our inquiry form. Please mention your intended application, and we will promptly respond with the latest material specifications for your layout.

Receive Complimentary Engineering Support

Choosing the right base material is only the beginning. Our experienced engineering team offers complimentary consultations to help you resolve stack-up challenges, thermal design questions, or surface finish selections when working with SAR15 aluminum substrates.

We will review your Gerber files, offer feedback on manufacturability, and suggest the best material combinations for your specific application—whether it’s a custom LED array, a power control board, or any device requiring improved heat dissipation. This early collaboration helps minimize trial-and-error and ensures your design intent matches practical production capabilities.

Request a Transparent Quote for Your Project

If you are planning a small pilot run or preparing for mass production, our quoting process is direct and transparent. Send us your PCB drawings or Gerber files, and our technical team will respond with more than just pricing—we provide feedback on feasibility, lead time estimates, and alternative solutions if needed.

Our quoting process includes:

●Confidential file handling (NDAs are available upon request).

●A detailed response within 24 hours, including engineering notes for clarification.

●Flexible lead time ranges and logistics options tailored to your project timeline and location.

Your inquiry is welcome. As a proven supplier of SAR15 PCBs, JarnisTech is ready to respond with the detail, flexibility, and consistency your project deserves.

FAQ: Shengyi SAR15 PCBs

1. What is the maximum continuous operating temperature for a SAR15 PCB?

SAR15 is rated for a maximum continuous operating temperature of up to 140°C, making it well-suited for thermally demanding applications.

2.Is this material suitable for high-frequency (RF) designs?

No, SAR15 is not recommended for high-frequency applications. Its properties are optimized for thermal management, not high-frequency signal integrity. For RF designs, other substrates would be a better fit.

3.How well does the white solder mask resist yellowing over time?

We use high-quality, thermally stable white solder masks specifically designed for LED boards. These are formulated to minimize yellowing and maintain high reflectivity throughout the product’s intended lifespan.

4.For panelized boards, is V-scoring or routing preferred for depaneling?

We strongly recommend routing (milling). It provides a cleaner, burr-free edge and induces less mechanical stress on the aluminum core, which contributes to long-term reliability. We can advise on the optimal routing paths for your panel design.

5.Are there recommended types of Thermal Interface Material (TIM) to use with SAR15?

The ideal TIM depends on your specific application. Thermal greases or phase-change materials often provide the lowest thermal resistance, while thermal pads are excellent for filling larger or less uniform gaps.

6.What is a typical production lead time?

For standard prototypes, our lead time is generally 7-10 business days. For mass production, the timeline depends on quantity and complexity. When you request a quote, we will provide a detailed and transparent schedule tailored to your project.

7.Can SAR15 be used for flexible or rigid-flex circuits?

No, SAR15 is an inherently rigid material due to its aluminum base and is not suitable for applications requiring flexibility.