Aluminum PCBs have become the go-to solution in industries where heat dissipation, durability, and efficiency are paramount. These circuit boards are commonly used in high-power applications, particularly LED lighting, automotive, and power equipment, thanks to their excellent thermal properties. As the global market for aluminum PCBs continues to grow, understanding the top manufacturers and what sets them apart becomes more relevant than ever. In this article, we explore ten leading aluminum PCB manufacturers around the world, detailing their strengths, offerings, and roles in the rapidly evolving PCB industry.

Why Aluminum PCBs Are Essential for Modern Electronics?

The Evolution of Electronics

In today’s tech-savvy world, devices are becoming smaller, faster, and, quite frankly, hungrier for power. As technology continues to push the boundaries, traditional printed circuit boards (PCBs) often find themselves struggling to manage the heat generated by these increasingly complex systems. This is where aluminum PCBs come into play.

Superior Thermal Management

One of the standout features of aluminum PCBs is their exceptional thermal conductivity, which typically ranges between 1 to 9.0 W/mK. This is significantly higher than traditional FR-4 PCBs, making aluminum an ideal choice for high-power applications. When electronic components generate heat, it can compromise performance and even lead to failure. Aluminum PCBs excel in dissipating this heat, keeping components cool and ensuring they operate efficiently. This is particularly important in high-power applications like LED lighting and automotive systems, where heat can be a real game-changer.

Durability and Reliability

Beyond just managing heat, aluminum PCBs offer improved durability. They are less prone to warping and damage compared to their traditional counterparts, making them ideal for demanding environments. For instance, in automotive applications, where exposure to vibrations and temperature fluctuations is common, aluminum PCBs demonstrate superior performance, leading to fewer failures and extended lifespans.

Enhanced Performance

The combination of thermal management and durability leads to improved performance across the board. This means longer lifespans for electronic devices and fewer failures—something that any PCB designer or manufacturer can appreciate. In industries where performance is key, aluminum PCBs are the unsung heroes, providing a robust solution to complex challenges.

Top Aluminum PCB Manufacturers Worldwide

As the demand for aluminum PCBs grows, so does the competition among manufacturers. Here, we spotlight ten key players in the aluminum PCB market, each bringing unique strengths and innovations to the table.

Comparison Table of Aluminum PCB Manufacturers

| Manufacturer | Manufacturing Capacity | Product Quality | Lead Time | Customer Service | Customer Satisfaction |

| Jarnistech | High (100K+ units/month) | Excellent (ISO 9001) | 3-4 weeks | Dedicated support team | 96% satisfied |

| Swimbi | Medium (50K units/month) | Very Good (IPC-A-600) | 3-5 weeks | Custom design support | 88% satisfied |

| Kingford PCB | Medium (30K units/month) | Excellent (MIL-PRF-31032) | 4-5 weeks | Strong client feedback | 90% satisfied |

| A-Tech Circuits | High (80K units/month) | Good (IPC-6012) | 4 weeks | Responsive service | 85% satisfied |

| AT&S | Very High (200K+ units/month) | Excellent (ISO 14001) | 5-7 weeks | Comprehensive support | 95% satisfied |

| Venture Electronics | Medium (60K units/month) | Very Good (UL Certified) | 3-4 weeks | Customer-centric approach | 87% satisfied |

| Circuitronix | High (90K units/month) | Excellent (IPC-A-600) | 4-6 weeks | Proactive communication | 89% satisfied |

| Shenzhen Boyunfa | Medium (40K units/month) | Good (IPC-6012) | 5 weeks | Good pre-sales support | 84% satisfied |

| MOKO Technology | High (70K units/month) | Excellent (ISO 9001) | 3-4 weeks | Fast turnaround, reliable | 91% satisfied |

| Wurth Elektronik | Very High (150K+ units/month) | Excellent (ISO/TS 16949) | 6-8 weeks | Strong technical support | 93% satisfied |

In-Depth Analysis of 10 Aluminum PCB Manufacturers

1.Jarnistech: High-Performance PCBs for Industrial Applications

Jarnistech has carved out a niche for itself by focusing on high-performance aluminum PCBs, especially for industrial applications. Our products are engineered to handle the toughest environments, making them ideal for heavy machinery and automotive industries. What sets Jarnistech apart is their use of state-of-the-art technology and a rigorous quality assurance process that ensures every PCB they produce is top-notch.

We understand that in industries where every second counts, you need a PCB that’s reliable, durable, and capable of handling serious workloads. With their strong focus on heat dissipation and durability, Jarnistech has earned a reputation for manufacturing some of the best aluminum PCBs in the business.

●Manufacturing Capacity: High monthly production capacity of over 100,000 units.

●Product Quality: ISO 9001 certified, rigorous testing including thermal cycling tests.

●Lead Time: 3-4 weeks.

●Customer Service: Dedicated support team focused on client needs.

●Customer Satisfaction: 96% of clients reported satisfaction, highlighting their reliability and product quality.

Case Study:

Jarnistech recently partnered with a leading automotive manufacturer to develop high-performance PCBs for electric vehicle (EV) battery management systems. The aluminum PCBs helped manage the significant heat generated during charging cycles, leading to improved battery efficiency and longevity.

2.Swimbi: Leading Supplier for LED and Lighting Applications

If you’re in the business of LED lighting or power management, Swimbi is likely a name you’ve heard before. Swimbi has long been a supplier of high-quality aluminum PCBs, focusing specifically on custom solutions for LED applications. They excel in designing PCBs that not only manage heat efficiently but also improve overall energy efficiency.

Swimbi offers flexibility in their production processes, ensuring that you get a custom-tailored solution every time. They’re the company you go to when you need something unique but don’t want to compromise on quality. From circuit design to manufacturing, Swimbi handles everything with precision and care.

●Manufacturing Capacity: Medium capacity of around 50,000 units per month.

●Product Quality: IPC-A-600 certification for high thermal management.

●Lead Time: 3-5 weeks.

●Customer Service: Custom design support for flexibility.

●Customer Satisfaction: 88% satisfaction rate, with clients appreciating their quick turnaround times.

Case Study:

Swimbi collaborated with a major lighting company to create custom aluminum PCBs for a new line of energy-efficient LED bulbs. The tailored design enhanced thermal dissipation, allowing the bulbs to maintain brightness while reducing energy consumption.

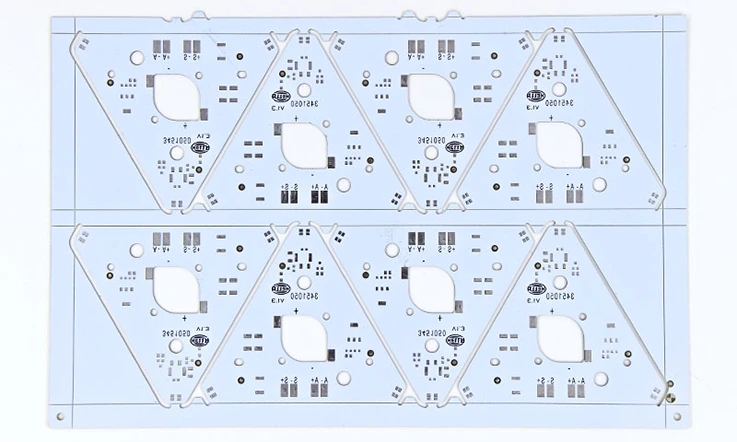

3.Kingford PCB: Custom Aluminum PCB Solutions

Kingford PCB is known for its high-quality, custom aluminum PCBs designed for industries like automotive and LED lighting. They excel in providing tailored thermal management solutions, ensuring efficient heat dissipation for high-power applications. Kingford’s emphasis on customer-driven designs makes them a trusted partner for businesses looking for specialized PCBs.

●Manufacturing Capacity: Medium capacity of about 30,000 units per month.

●Product Quality: MIL-PRF-31032 standards for high-reliability applications.

●Lead Time: 4-5 weeks.

●Customer Service: Strong client feedback and communication.

●Customer Satisfaction: 90% satisfied, often noting the quality of custom solutions.

Case Study:

Kingford PCB worked with a defense contractor to produce aluminum PCBs for radar systems. The robust thermal properties ensured reliable operation in high-temperature environments, exceeding project specifications and contributing to mission success.

4.A-Tech Circuits: Aluminum PCBs for LED and Automotive Industries

A-Tech Circuits is a global supplier that focuses heavily on aluminum PCB production, particularly for the LED and automotive industries. Their aluminum boards are designed with an emphasis on thermal conductivity and reliability, perfect for high-performance applications that require robust heat management.

●Manufacturing Capacity: High capacity of around 80,000 units per month.

●Product Quality: IPC-6012 standards for reliability.

●Lead Time: 4 weeks.

●Customer Service: Responsive service appreciated by clients.

●Customer Satisfaction: 85% satisfaction, with clients frequently mentioning their customer service quality.

Case Study:

A-Tech Circuits provided aluminum PCBs for a new line of high-performance LED headlights in a major automotive brand. Their designs helped reduce heat buildup, improving the lifespan of the LED components significantly.

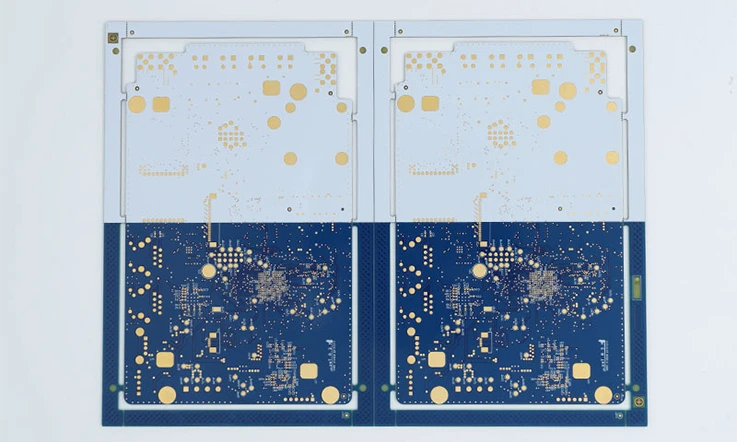

5.AT&S: High-Tech Aluminum PCBs for Industrial Use

AT&S is a major player in the global PCB market, offering cutting-edge aluminum PCBs designed for industrial and high-tech applications. They are known for their innovation in PCB technology, including high-density interconnect (HDI) designs and advanced thermal management solutions, making them a top choice for demanding environments.

●Manufacturing Capacity: Very high capacity of over 200,000 units per month.

●Product Quality: ISO 14001 certification, extensive testing.

●Lead Time: 5-7 weeks.

●Customer Service: Comprehensive support for clients.

●Customer Satisfaction: 95% of customers report satisfaction, particularly regarding their innovative solutions.

Case Study:

AT&S partnered with an industrial automation company to develop high-density interconnect (HDI) aluminum PCBs for robotics applications. The result was a PCB that could withstand harsh conditions while maintaining precise control over robotic movements.

6.Venture Electronics: High-Quality Aluminum PCBs for High-Power Applications

Venture Electronics offers aluminum PCBs designed for heat dissipation and reliability, making them an excellent choice for high-power applications in industries such as automotive and renewable energy.

●Manufacturing Capacity: Medium capacity of around 60,000 units per month.

●Product Quality: UL certification for safety-critical applications.

●Lead Time: 3-4 weeks.

●Customer Service: Customer-centric approach receives positive reviews.

●Customer Satisfaction: 87% satisfied, often praising their product reliability.

Case Study:

Venture Electronics supplied aluminum PCBs for a renewable energy startup’s solar inverters. Their solutions effectively managed the heat generated during power conversion, ensuring optimal performance in varying weather conditions

7.Circuitronix: Global Leader in High-Performance Aluminum PCBs

Circuitronix is a global supplier focusing on high-performance aluminum PCBs. They cater to industries that require advanced thermal management solutions, including automotive and aerospace sectors.

●Manufacturing Capacity: High production capacity of about 90,000 units per month.

●Product Quality: IPC-A-600 certification ensures quality.

●Lead Time: 4-6 weeks.

●Customer Service: Proactive communication ensures smooth experiences.

●Customer Satisfaction: 89% satisfaction, with clients noting their excellent technical support.

Case Study:

Circuitronix collaborated with an aerospace company to produce aluminum PCBs for satellite communication systems. The robust thermal management allowed for uninterrupted signal transmission, proving essential for mission-critical operations.

8.Shenzhen Boyunfa: High-End Aluminum PCBs for LED Applications

Shenzhen Boyunfa specializes in high-end aluminum PCBs, particularly for LED lighting and energy-saving systems. Their focus on quality and innovation makes them a strong player in the market.

●Manufacturing Capacity: Medium capacity of around 40,000 units per month.

●Product Quality: Meets IPC-6012 standards to ensure reliable performance and durability.

●Lead Time: Average lead time of 5 weeks.

●Customer Service: Boyunfa offers good pre-sales support, particularly helpful for startups and small businesses.

●Customer Satisfaction: 84% customer satisfaction, with positive feedback on the flexibility of their design process.

Case Study:

Shenzhen Boyunfa worked with a startup specializing in street lighting. The project required aluminum PCBs with exceptional thermal performance to handle the heat generated by high-intensity LEDs. Boyunfa’s PCBs not only met the thermal requirements but also reduced overall production costs, allowing the startup to expand its business rapidly across multiple cities.

9.MOKO Technology: One-Stop Aluminum PCB Manufacturing

MOKO Technology offers a full range of aluminum PCB services, from design to production. They are known for their excellent customer support and fast turnaround times, making them ideal for both prototypes and mass production.

●Manufacturing Capacity: High monthly output of about 70,000 units.

●Product Quality: ISO 9001 certified, ensuring strict adherence to quality management practices.

●Lead Time: 3-4 weeks for standard orders, with an option for expedited services.

●Customer Service: MOKO Technology is known for its reliable customer service, which includes fast and efficient communication channels.

●Customer Satisfaction: 91% satisfaction rate, with clients particularly appreciative of their short lead times and consistent product quality.

Case Study:

MOKO Technology worked closely with an automotive lighting company to deliver aluminum PCBs for their next-generation headlights. The PCB design offered improved heat dissipation, enabling brighter and more energy-efficient headlights. MOKO’s quick turnaround allowed the client to launch their product ahead of schedule, gaining a competitive advantage in the market.

10.Wurth Elektronik: Advanced Aluminum PCB Solutions

Wurth Elektronik is a German-based company known for its advanced PCB solutions, including aluminum PCBs. Their focus on reliability and high-end thermal management positions them as a leader in industries like automotive and telecommunications.

●Manufacturing Capacity: High volume capacity of 150,000 units per month, catering to large-scale industries.

●Product Quality: Certified under ISO/TS 16949, Wurth Elektronik is known for its precision manufacturing and adherence to automotive standards.

●Lead Time: Slightly longer at 6-8 weeks due to the complexity of projects handled.

●Customer Service: Strong technical support is a highlight, especially for clients requiring intricate designs or customization.

●Customer Satisfaction: 93% satisfaction rate, with many customers praising their ability to deliver highly specialized aluminum PCBs.

Case Study:

Wurth Elektronik recently supplied aluminum PCBs for a medical equipment manufacturer that required high reliability and minimal thermal interference. The PCBs played a crucial role in ensuring the stable operation of imaging systems, significantly enhancing the diagnostic precision of the equipment.

Aluminum PCB Manufacturing: A Global Market Overview

The global market for aluminum PCBs is growing at an exponential rate, driven primarily by the increasing demand for energy-efficient solutions and the need for effective thermal management in high-power applications. From automotive to renewable energy, aluminum PCBs are being used across a wide range of industries to improve performance and extend product lifespan.

Asia, particularly China, remains the dominant player in aluminum PCB manufacturing, with Shenzhen serving as a key hub. However, manufacturers from North America and Europe are also stepping up, offering innovative solutions and focusing on sustainability. As the demand for high-performance electronics continues to grow, so too will the need for reliable aluminum PCBs that can handle the heat—literally and figuratively.

Key Factors to Consider When Choosing an Aluminum PCB Supplier

Selecting the right aluminum PCB supplier is like choosing the right tool for a job—get it wrong, and it could mess up the whole operation. Here are some key factors to consider:

●Thermal Management Capabilities: Ensure the supplier can provide boards that effectively dissipate heat, particularly if you’re working with high-power applications like LEDs or power supplies.

●Custom Design Services: Look for suppliers who can offer customized solutions tailored to your specific needs. Not every project is the same, and having a partner who can adapt to your requirements is worth its weight in gold.

●Quality Assurance: Make sure the manufacturer follows strict quality assurance processes to ensure that the PCBs meet industry standards. In the electronics world, there’s no room for sloppiness.

●Production Capacity: Depending on your needs, you’ll want to choose a supplier with the right balance of production capacity and flexibility. Smaller batches might require a more specialized supplier, while large-scale production will demand more robust capabilities.

●Pricing and Lead Time: Balancing cost with lead time is always a challenge, but it’s a factor that can’t be ignored. Make sure to get clear timelines and competitive pricing to avoid unexpected delays or budget overruns.

Wrapping Up

The future looks bright for aluminum PCBs. As industries continue to push the boundaries of what’s possible, the demand for PCBs that can manage heat, provide durability, and ensure performance will only increase. Whether it’s for LED lighting, automotive electronics, or power management, aluminum PCBs will continue to play a key role in the evolution of modern technology.

From the suppliers we’ve highlighted to the growing global market, aluminum PCBs are more than just a trend—they’re a long-term solution for industries that need robust, reliable, and high-performance circuit boards. And if you’re working in electronics, it’s worth keeping an eye on the innovations coming out of this space.

Reach out to one of the manufacturers listed above to get your project started. Each of these companies has a proven track record of delivering high-quality aluminum PCBs, backed by strong customer satisfaction and industry-specific expertise.

Frequently Asked Questions (FAQ)

1. What industries benefit most from aluminum PCBs?

Aluminum PCBs are widely used in industries where heat management is crucial. Some key industries include LED lighting, automotive, telecommunications, consumer electronics, and renewable energy. In these sectors, the ability of aluminum PCBs to dissipate heat effectively ensures the longevity and reliability of electronic components.

2. How do aluminum PCBs compare to traditional FR-4 PCBs?

Aluminum PCBs offer superior thermal conductivity and durability compared to FR-4 PCBs, making them more suitable for high-power applications. While FR-4 is cheaper and more versatile for low-power applications, aluminum PCBs excel in environments that require better heat dissipation, such as automotive systems and LED lighting.

3. What factors should I consider when selecting an aluminum PCB manufacturer?

When selecting a manufacturer, consider their production capacity, product quality certifications (like ISO or IPC standards), lead time, customer service, and their experience with your industry. It’s also essential to check their track record with similar projects and their ability to meet custom design requirements.

4. Can aluminum PCBs be used in flexible applications?

Although aluminum PCBs are typically more rigid than their FR-4 counterparts, there are ways to design them with flexibility in mind. Some manufacturers offer hybrid solutions that combine aluminum with flexible materials for specialized applications, such as automotive or medical devices that require bending or twisting.

5. How does the cost of aluminum PCBs compare to other PCB materials?

Aluminum PCBs are generally more expensive than traditional FR-4 boards due to the cost of raw materials and the complexity of the manufacturing process. However, their enhanced performance and durability often justify the additional cost, especially in high-heat applications.

Related Posts:

1. Differentiating FR4 Glass Fiber and Aluminum Substrate for PCBs

2.Aluminum Base PCBs: The Future of High-Power Electronics

3.Overview of LED Aluminum PCB

4.Significance of Aluminum Clad PCBs in Advancing Electronic Device

5.How Leveraging Aluminum PCB Substrates: in Your Next Stackup Design?