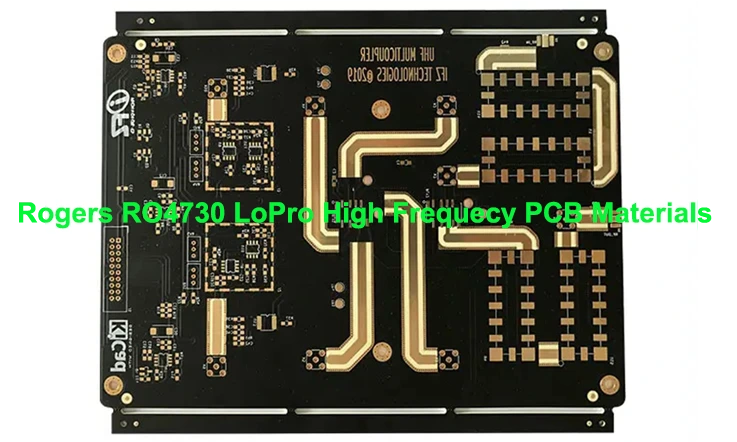

RO4730 LoPro PCB substrates by Rogers Corporation have established themselves as a leading choice for demanding electronic applications. With their exceptional electrical properties, reliability, and design flexibility, these substrates pave the way for high-performance electronic systems across various industries. From wireless communication to automotive radar and satellite technology, RO4730 substrates deliver unmatched signal integrity, low loss, and consistent circuit performance. This article explores the key features and benefits of RO4730 substrates, highlighting their significant contributions to the advancement of electronic devices.

Overview of Rogers RO4730 LoPro

RO4730 LoPro antenna grade laminates, a cutting-edge solution that offers exceptional compatibility with conventional FR4 and high temperature lead-free solder processing. With this advanced technology, the need for special treatment required with traditional PTFE-based laminates for plated through hole preparation is eliminated. As a result, designers can enjoy a cost-effective alternative to conventional antenna technologies, optimizing both price and performance.

The RO4730 dielectric materials are engineered with precision resin systems, specifically tailored to deliver the necessary properties for optimal antenna performance. The coefficients of thermal expansion (CTEs) in both the X and Y directions closely match that of copper. Consequently, stresses in the printed circuit board antenna are significantly reduced. These materials exhibit excellent plated through hole reliability, boasting a low Z-axis CTE and a typical glass transition temperature exceeding an impressive 280°C (536°F).

The RO4730 LoPro laminate excels in providing antenna designers with outstanding thermo-mechanical properties and electrical characteristics. With a dielectric constant (Dk) of 3.0 and a loss tangent (Df) of 0.0023 measured at 2.5 GHz, these laminates enable substantial gain values while minimizing signal loss. Furthermore, the materials are available with a demonstrated low PIM (Passive Intermodulation) performance, showcasing values better than -154 dBc (using Rogers’ internal test method).

Overall, the RO4730 LoPro antenna grade laminates present a compelling proposition for PCB manufacturers. With their exceptional compatibility, cost-effectiveness, and optimized performance, these laminates empower designers to create superior antenna solutions without compromising on quality or efficiency.

Feature of Rogers RO4730 LoPro PCB Materials

The Rogers RO4730 PCB materials offer a range of impressive features that make them highly desirable for various applications:

1.Low Loss Dielectric with Low Profile Foil:

The RO4730 laminate incorporates a low loss dielectric material, ensuring minimal signal loss and high signal integrity. The low profile foil used in the construction further enhances performance and allows for precise impedance control.

2.Unique Filler/Closed Microspheres:

The RO4730 laminate utilizes a unique filler system with closed microspheres, contributing to its exceptional electrical and mechanical properties. This formulation enhances the laminate’s overall performance and reliability.

3.Low Z-Axis Coefficient of Thermal Expansion (CTE):

The RO4730 material exhibits a low Z-axis CTE of approximately 40 ppm/°C. This characteristic helps minimize stress and provides excellent dimensional stability, especially in applications where temperature variations occur.

4.High Glass Transition Temperature (Tg):

Similar to the renowned RO4000 laminate, the RO4730 laminate boasts a high Tg exceeding 280°C. This elevated Tg ensures the material remains stable and reliable even under high-temperature operating conditions.

5.Low Thermal Coefficient of Dielectric Constant (TCDk):

The RO4730 laminate features a low TCDk of around 23 ppm/°C. This attribute ensures that the dielectric constant remains consistent over a wide temperature range, resulting in stable electrical performance.

6.Specially Formulated Thermoset Resin System/Filler:

The RO4730 laminate incorporates a carefully formulated thermoset resin system and filler combination. This formulation is optimized to deliver superior electrical properties, mechanical strength, and thermal stability.

7.Environmentally Friendly:

The materials used in the production of RO4730 laminates adhere to environmentally friendly practices and regulations. This aspect ensures compliance with sustainability standards while maintaining high-performance capabilities.

Benefits of of Rogers RO4730 LoPro

The Rogers RO4730 LoPro PCB substrates offer a wide range of benefits, making them an excellent choice for various electronic applications. These benefits include:

1. Reduced PIM (Passive Intermodulation): The RO4730 substrates are engineered to minimize passive intermodulation, ensuring clean and reliable signal transmission without interference or distortion.

2. Low Insertion Loss: These substrates exhibit low insertion loss, which means that the electrical signals experience minimal attenuation as they pass through the circuit. This characteristic allows for efficient signal propagation and improved overall system performance.

3. Match DK to 3.0 Materials: The RO4730 substrates have a dielectric constant (DK) closely matched to 3.0 materials. This feature simplifies the design process by facilitating impedance matching and optimizing signal integrity.

4. Low Density/Lightweight: The RO4730 substrates have a low density, making them lightweight. In fact, they are approximately 30% lighter than PTFE/glass materials. This characteristic is particularly advantageous in applications where weight reduction is critical, such as aerospace or portable devices.

5. Design Flexibility: The RO4730 substrates offer design flexibility, allowing engineers and designers to create complex circuit layouts and incorporate various features. This flexibility enables innovative designs and optimized performance for specific applications.

6. Automated Assembly Compatible: These substrates are compatible with automated assembly processes, streamlining the production and assembly of PCBs. This compatibility enhances manufacturing efficiency and reduces the risk of errors or inconsistencies.

7. Consistent Circuit Performance: The RO4730 substrates ensure consistent circuit performance due to their stable electrical properties and reliable manufacturing processes. This consistency is essential for maintaining high-quality and reliable electronic systems.

8. Low TCDk: The RO4730 substrates exhibit a low thermal coefficient of dielectric constant (TCDk). This characteristic means that the dielectric constant remains stable across a wide temperature range, ensuring predictable electrical performance under varying environmental conditions.

9. Ease of Fabrication: These substrates are easy to fabricate, allowing for efficient and cost-effective production processes. They can be easily machined, drilled, and assembled, simplifying the manufacturing workflow.

10. PTH Process Capability: The RO4730 substrates have excellent plated through hole (PTH) process capability. They can withstand the necessary treatments and preparations required for reliable PTH connections, ensuring robust and durable PCB assemblies.

11. Halogen-Free: The RO4730 substrates are halogen-free, offering an environmentally friendly and sustainable solution. This characteristic ensures compliance with regulatory requirements and promotes the use of eco-friendly materials.

12. Lead-Free Process Compatible: These substrates are compatible with lead-free processes, aligning with industry trends and requirements. They can be used in manufacturing processes that adhere to lead-free soldering and assembly techniques.

13. RoHS Compliant: The RO4730 substrates are RoHS (Restriction of Hazardous Substances) compliant. This compliance signifies that they meet the standards and restrictions set forth by the RoHS directive, ensuring the absence of hazardous substances in the materials.

All in all, the Rogers RO4730 LoPro PCB substrates offer a comprehensive set of benefits, including improved signal performance, design flexibility, lightweight construction, compatibility with automated assembly, consistent circuit performance, low thermal coefficient, ease of fabrication, PTH process capability, halogen-free composition, lead-free process compatibility, and RoHS compliance. These features make them an ideal choice for applications that require high performance, reliability, environmental compliance, and efficient manufacturing processes.

Disadvantages and Challenges of RO4730 LoPro PCB Substrates

While RO4730 LoPro PCB substrates offer numerous advantages, it’s important to consider some potential disadvantages and challenges associated with their use. These include:

1. Cost: RO4730 substrates can be relatively more expensive compared to traditional PCB substrates. The advanced materials and manufacturing processes involved in their production contribute to higher costs. This factor may limit their adoption in cost-sensitive applications.

2. Limited Availability: RO4730 substrates may have limited availability compared to more commonly used PCB materials. This can lead to longer lead times and potential supply chain challenges, especially for large-scale production or time-sensitive projects.

3. Specialized Fabrication: The fabrication and processing of RO4730 substrates require specialized techniques and equipment. This can pose challenges for PCB manufacturers who may need to invest in additional resources or undergo training to work with these substrates effectively.

4. Material Handling: RO4730 substrates are lightweight and relatively fragile compared to traditional PCB materials like FR-4. Care must be taken during handling and assembly processes to prevent damage or delamination of the substrate.

5. Thermal Management: While RO4730 substrates offer low thermal coefficient of dielectric constant (TCDk), they may not have the same level of thermal conductivity as materials like aluminum or copper. In applications where heat dissipation is critical, additional measures may be required to manage thermal issues effectively.

6. Compatibility with Lead-Free Processes: While RO4730 substrates are generally lead-free process compatible, some variations or specific applications might require additional evaluation and testing to ensure compatibility with specific lead-free soldering processes.

7. Design Considerations: The unique electrical properties and characteristics of RO4730 substrates may require careful consideration during the design phase. Impedance matching, signal routing, and other factors may need to be optimized to achieve optimal performance with these substrates.

8. Environmental Impact: While RO4730 substrates are halogen-free and RoHS compliant, their production still involves the use of specialized materials and processes that may have an environmental impact. Care should be taken to properly manage and dispose of waste materials generated during fabrication.

By understanding and addressing these factors, engineers and designers can make informed decisions regarding the use of RO4730 LoPro PCB substrates in their electronic designs.

Typical Applications

The Rogers RO4730 LoPro PCB substrates find application in various industries and technologies. Some typical applications include:

1.Base Station Antennas:

The high-performance characteristics of RO4730 substrates make them well-suited for base station antennas used in wireless communication systems. These substrates enable efficient signal transmission and reception, contributing to improved network coverage and reliability.

2.Cellular Base Station Antennas and Power Amplifiers:

RO4730 substrates are commonly employed in cellular base station antennas and power amplifiers. Their low loss and low PIM properties ensure excellent signal quality, leading to enhanced cellular network performance.

3.RF Identification Tags:

The RO4730 substrates are utilized in RF identification tags, commonly known as RFID tags. These tags are used in various applications such as inventory management, asset tracking, and access control systems.

4.Automotive Radar and Sensors:

Given their exceptional electrical properties and low insertion loss, RO4730 substrates are extensively used in automotive radar systems and sensors. These applications require reliable and high-performance PCB materials for accurate detection and collision avoidance.

5.LNBs (Low-Noise Block Converters) for Direct Broadcast Satellites:

RO4730 substrates are employed in LNBs used in direct broadcast satellite systems. LNBs receive satellite signals and convert them to lower frequencies for further processing. The high-frequency performance and stability of these substrates ensure optimal signal reception and transmission.

6.Satellites:

RO4730 substrates are utilized in various components and systems within satellites. These substrates provide the necessary reliability, thermal stability, and electrical performance required for satellite communication, navigation, and other functions.

Conclusion

RO4730 LoPro PCB substrates from Rogers Corporation exemplify the pursuit of excellence in high-performance electronics. With reduced PIM, low insertion loss, and a dielectric constant (DK) matched to 3.0 materials, these substrates offer superior signal integrity and optimized performance. Their low density and design flexibility make them an ideal choice for lightweight applications, while their compatibility with automated assembly processes enhances manufacturing efficiency.

Additionally, their halogen-free and RoHS compliance further emphasize their commitment to environmental sustainability. As technology continues to evolve, RO4730 substrates will undoubtedly play a pivotal role in shaping the future of advanced electronic systems. Experience the power of RO4730 LoPro PCB substrates and unlock new possibilities for your next-generation electronic designs.

Our services

Rogers PCB Laminates & Series