Silicon Nitride Ceramic Printed Circuit Boards (PCBs) mark a progression in the field of electronics showcasing enhanced capabilities for use, in high power high frequency and challenging environmental settings. This special ceramic PCB circuit boards has thermal conductivity facilitating effective heat dispersion while also possessing exceptional dielectric characteristics that support seamless high frequency functionality without notable signal degradation.

Moreover they showcase durability against impacts, vibrations and varying temperatures which renders them suitable for use in the aerospace, automotive, defense and telecommunications sectors. This piece will delve into how Silicon Nitride Ceramic PCBsre manufactured and underscore their benefits in contrast, to other types of PCB substrate materials. We will also investigate advancements and the potential of Silicon Nitride Ceramic PCBs as a pivotal technology that will foster innovation and enhance the efficiency of sophisticated electronic devices and systems.

What Are Silicon Nitride Ceramic PCBs?

Silicon Nitride Ceramic PCBs are a kind of printed circuit board that use silicon nitride ceramic as their base material providing advantages compared to traditional substrates like FR4 or polyimide. Silicon nitride is increasingly preferred as a high performance ceramic material, them provide outstanding thermal conductivity, robust strength and hardness and excellent resistance for chemicals. This PCB circuit boards allows for thermal regulation and temperature efficiency resulting in electronic devices that are more dependable and long lasting.

Silicon Nitride Ceramic PCBs are often used in applications that require power operate at high frequencies and face harsh environmental conditions. This is because they naturally resist corrosion and oxidation have thermal and physical endurance and exhibit excellent mechanical strength. The introduction of silicon ceramic PCBs has led to advancements in circuit designs increased levels of integration and enhanced operational efficiency, across various electronic systems.

Manufacturing Process of Silicon Nitride Ceramic PCBs

The production method for Silicon Nitride PCBs, maybe have differ based on the particular needs of the application. Nonetheless in general most Silicon Nitride Ceramic PCBs are manufactured following these steps:

● Substrate Material Preparation: molding the Silicon Nitride material to the required size and thickness followed by polishing the surface to achieve a sleek and uniform appearance.

● Metallization: A fine metal coating, usually made of tungsten or molybdenum is applied to the surface through method. Such as physical vapor deposition or chemical vapor deposition. And the metal layer acts as the base for plating process.

● Plating: Electroplating is used to deposit plating layers of copper or other metals onto the seed layer. The formation of copper traces involves the creat of a metal film through a patterning process. Then etched away using photolithography to achieve the intended circuit pattern.

● Via Formation: Holes are drolled in the ceramic base boards and metal is deposited into them to create vias for electrical connections, between various layer of the circuit board.

● Sintering: The completed circuit board, now equipped with layers of copper traces and vias undergoes sintering in a high temperature furnace. This process involves solidifying the substrate together with the copper layers and vias effectively merging them into a unified unit.

● Surface Finishing: The PCB is finished by applying a final layer of metal or protective coatings to create a high-quality surface finish.

Fabrication Silicon Nitride PCBs involves a series of intricate steps that usually demand specialized skills and equipment to ensure top notch dependable products that cater to specific application need.

Comparison with Other PCB Substrates

Silicon Nitride Ceramic PCBs show thermal efficiency making them perfect for use in high temperature settings. They provide high frequency performance when compared to materials. Such as FR4 which experience increased dielectric losses at higher frequencies. Additionally these PCB are known for their reliability and ability to withstand shocks and vibrations without issues unlike polyimide and Rogers materials that’re more susceptible to cracking or delamination.

Additionally Silicon Nitride Ceramic PCB can be made thinner than other substrate, reducing the overall size and weight of electronic devices. They are particularly ideal for operation harsh environments as they exhibit superior resistance to high levels of moisture, radiation and corrosive substances when compared to substrates like FR4. This quality renders them an option for rigorous usage scenarios.

Challenges and Limitations of Silicon Nitride Ceramic PCBs

Silicon Nitride tends to be pricier compared to traditional PCB materials leading to higher production expenses. The process of manufacturing Silicon Nitride PCBs is more intricate and demands specialized tools and expertise which further drives up the costs. Despite its strength and hardness Silicon Nitride is somewhat brittle making the Ceramic PCBs prone to cracking or breaking under strain during fabrication or use. Moreover due to the properties of Silicon Nitride and the complexities involved in its production there might be limitations, in designing and arranging the circuit board. Although Silicon Nitride is gaining popularity it still lags behind traditional PCB substrate materials in terms of widespread use.

Silicon Nitride Ceramic Description

Silicon nitride, also known as Si3N4 is a Top ceramic material known for its remarkable strength and resistance to chemicals along with its high melting point. It stands out for its ability to withstand heat shock and impressive toughness against fractures making it very durable against shocks and impacts. While having characteristics similar to silicon carbide (SiC) silicon nitride surpasses, in its capacity to resist heat shocks.

Process of manufacturing silicon nitride, includes heating silicon powder in an oxygen environment at temperatures ranging from 1300 to 1400 degrees then molding it into specific shapes. Silicon nitride is valued for its stability, under temperatures and its exceptional hardness making it widely used across various industries.

Silicon nitride is commonly used in bearings in situations where there are high temperature and fast speed since its outstanding qualities. Its impressive combination of toughness and hardness significantly improves performance in demanding applications.

Ceramic – Si3N4 (Silicone Nitride)- Material Specifications

| Property | Unit | Si3N4 |

| Thermal | W/mK | 85 |

| Maximum Operating Temperature (MOT) | °C | >800 |

| Coefficient of Thermal Expansion (CTE) | x 10¯⁶/K | 2.6 |

| Dielectric Constant | – | 9 |

| Signal Loss | x 10¯³ | 0.2 |

| Light Reflectivity | % | – |

| Breakdown Voltage | KV/mm | 15 |

| Rupture Strength | Mpa | 800 |

Silicone Nitrides product offers appealing features, such as a low coefficient of thermal expansion (CTE) strong rupture resistance and the ability to function at temperatures above 800°C. Its lack of water absorption makes it suitable, for packaging. Additionally it is well suited for frequency uses thanks to its minimal signal loss.

Furthermore the thermal conductivity shows performance when using Al2O3 and AlN at elevated temperatures with values falling within the range of 85 to 90W/mK. Through the integration of these characteristics we’ve crafted a PCB that boasts durability, longevity and flexibility rendering it an ideal choice, for a diverse array of uses.

Silicon Nitride Is Currently Employed in a Range of Industries

Silicon Nitride is applied in fields such, as automotive, aerospace and energy sectors. As it is widely utilized across industries because of its exceptional performance.

Silicon Nitride is widely used in the sector to make engine parts. Such as bearings and valves providing excellent durability, strength and resistance to heat. In the aerospace field Silicon Nitride is utilized for creating turbine blades and high temperature applications such, as heat exchangers and environmental control systems.

Silicon Nitride ceramics materials have high electrical and thermal conductivity making them perfect for producing parts, in solar cells and solid oxide fuel cells. Therefore, the energy industry also uses Silicon Nitride in the form of ceramics.

Silicon Nitride’s versatility and exceptional attributes have made it a popular choice, across industries enhancing the effectiveness and functionalities of diverse applications. In addition, as Silicon Nitride is commonly utilized in manufacturing cutting tools, ball bearings and various industrial parts because of its mechanical and thermal properties.

JarnisTech Provide for Incomparable Silicon Nitride Substrate PCB

We would like to invite your team to reach out to us if you come across any problems with PCBs. At JarnisTech, a PCB manufacturer we are dedicated, to delivering functional and reliable PCB to our customers.

Our professional team has the knowledge and ability to handle any connectivity issues concerning PCB stack up layers. When you collaborate with JarnisTech you can trust that your PCB will be overseen by professionals giving you a feeling of assurance and trust in knowing that your PCB need are being taken care of by capable individuals.

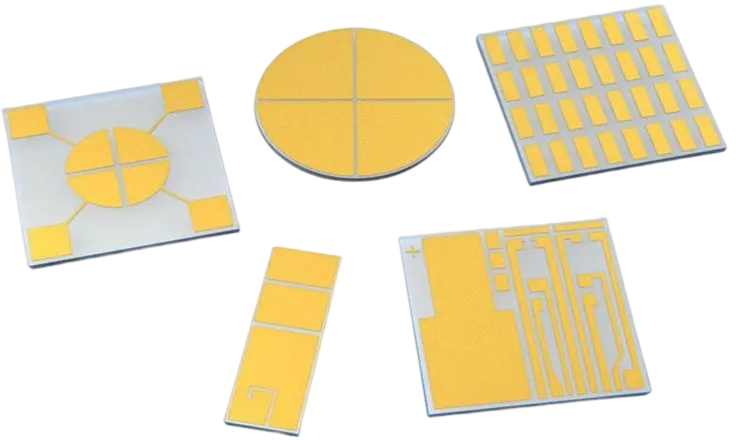

Capability of Manufacturing Silicon Nitride Ceramic PCB

Our circuit board made from Silicon Nitride Substrate is a top notch option for anyone looking for bending resistance and durability. It can withstand situations without breaking and is highly resilient, against moisture related harm. Additionally its outstanding thermal conductivity makes it perfect for tasks that demand power and rapid temperature adjustments.

In our company we strive to make the PCB design and manufacturing process more user friendly beginning with the layout of your PCB. Our skilled engineers will promptly address your questions and offer all the essential information needed for a flawless PCB design. With over ten years of experience, in the PCB industry our team is fully capable of handling any inquiries related to Silicon Nitride Substrate.

We specialize in producing PCBs that generate energy well as PCBs for RF applications and military use. Our expertise lies in creating custom designs using the software like Altium and Kicad. If you already have a PCB design ready we can help speed up the manufacturing process for you. Don’t hesitate any longer; get in touch with us away to talk to our team. Our customer service representatives are here 24/7 to assist you. By placing an order, with us we can ensure quick and efficient delivery of your Silicon Nitride Substrate PCB.

Sum Up

JarnisTech-Excellent Silicon Nitride Substrate Supplier

This in-depth FAQ guide explores Silicon Nitride. As we known that it is a remarkable material known for its exceptional dielectric and thermal conductivity properties that are coupled with exceptional mechanical strength.

When it comes to high technology needs Silicon Nitride Ceramic PCB substrates are strongly suggested for top notch performance. JarnisTech excels in providing Silicon Nitride Ceramic PCB manufacturing and assembly services renowned for their impressive outcomes. To discover more we encourage you to contact us for in depth details. Our team is enthusiastic about assisting you and having a conversation, about your Silicon Nitride ceramic PCB project requirements thoroughly. We promise to offer tailored solutions that cater to your needs and ensure top notch performance and reliability.

Related Posts:

●Overview of Alumina Substrate

●How Layout a Multilayer Ceramic PCB Stack-ups?

●How to Design a Ceramic Circuit Board?

●Leading Global 12 Ceramic PCB Manufacturers

●Manufacturing Standards for Ceramic PCB Production

●What is Ceramic Packages and Its Types?

PCB Fabrication

Ceramic PCB Manufacturing & Assembly