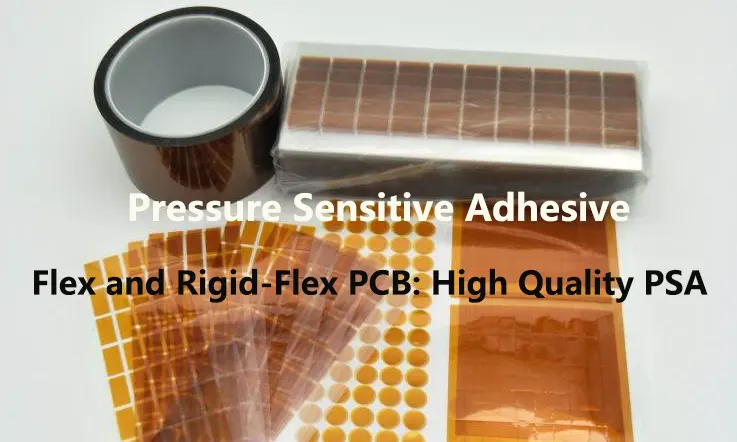

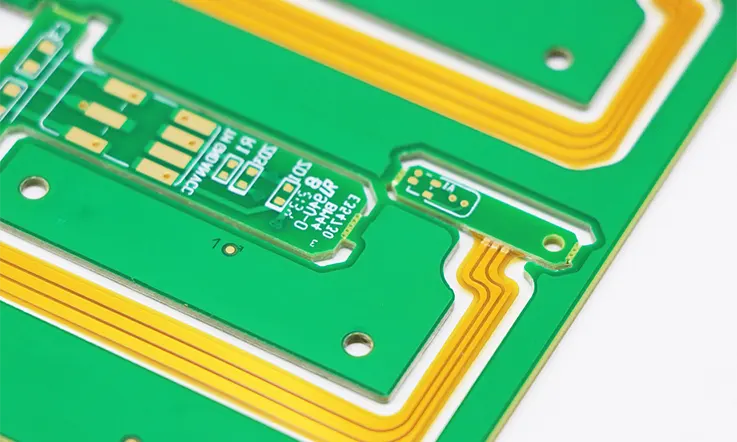

Pressure-Sensitive Adhesives (PSAs) are a class of polymeric bonding materials applied in the assembly of modern electronic devices. Their use is prevalent in the creation of flexible printed circuits (FPCs) and rigid-flex boards. This guide details the technical specifications, chemical foundations, application methodologies, and failure analysis of PSAs. The information is structured for personnel involved in technical specification, application, and procurement who require a functional understanding of how to select, apply, and validate PSA solutions for demanding electronic products. The objective is to connect material science with the practical workflows of circuit board creation, component sourcing, and final assembly.

The Fundamental Principles of Pressure-Sensitive Adhesion

Pressure-sensitive adhesion occurs through a physical phenomenon. Unlike structural adhesives that cure via chemical reactions, PSAs exist in a semi-solid condition known as a viscoelastic state. This state combines the characteristics of a viscous fluid and an elastic solid. When light pressure is applied, the PSA flows to “wet out” the substrate surface, creating intimate contact. This proximity allows intermolecular forces, primarily Van der Waals forces, to form a bond. This pressure-activated bonding at ambient temperatures makes PSAs suitable for assembling thermally sensitive components and flexible substrates. The ultimate strength of the bond is determined by the adhesive’s ability to wet the surface and its internal cohesive strength.

Pressure-Sensitive Adhesive (PSA) Application in FPC & Rigid-Flex Assembly

The choice of bonding material directly influences the manufacturing process and final performance of flexible and rigid-flex circuits. Pressure-sensitive adhesives (PSAs) present specific advantages in these assemblies by addressing demands for miniaturization, reliability, and production efficiency.

1.Streamlined Assembly Cycles

●PSAs bypass thermal curing processes, such as ovens and presses, required for thermoset adhesives. Bonding occurs at room temperature with applied pressure, which directly shortens assembly timelines, lowers energy usage, and reduces the dependency on specialized capital equipment.

2.Enhanced Mechanical Reliability

●The viscoelastic properties of PSAs enable the absorption and dissipation of mechanical shock and vibration. Within a rigid-flex assembly exposed to dynamic bending, the PSA forms a compliant layer. This mitigates stress on solder joints and sensitive components, contributing to the final product’s long-term stability.

3.Precise and Uniform Bond Lines

●PSAs are supplied with precise thickness tolerances, generally from 25 to 250 microns (1 to 10 mils). This feature ensures a uniform gap between substrates, a condition that supports predictable electrical characteristics and mechanical stability in high-density designs.

4.Effective Bonding of Diverse Materials

●Assemblies often combine materials like polyimide films, FR-4, stainless steel, and aluminum. PSAs adhere effectively to these varied substrates. This capability allows for durable bonds between materials with different coefficients of thermal expansion (CTE), preventing the introduction of harmful stress during thermal cycling.

5.Support for Complex Geometries

●The tape format of PSAs permits precision die-cutting or laser-cutting into complex shapes. This capability allows for selective adhesive placement in highly specific patterns, facilitating the intricate layouts required in applications like wearable technology and medical devices.

Leveraging these PSA attributes allows for the fabrication of more reliable and sophisticated electronic devices.

An Overview of PSA Chemical Systems

The performance envelope of a pressure-sensitive adhesive is defined by its core polymer chemistry. The fundamental differences between these systems determine their suitability for specific electronic assembly applications.

Acrylic Adhesives

Acrylic-based PSAs are a versatile and broadly used chemical system in electronics. Formulated from acrylic acid ester polymers, their properties can be modified by altering the monomer composition and polymer architecture.

●Environmental Endurance: They exhibit high resistance to UV radiation, oxidation, and temperature shifts, a trait suited for applications requiring long-term device reliability.

●Chemical Stability: The stable molecular structure offers good resilience against many solvents, oils, and plasticizers sometimes present in assemblies.

●Adjustable Adhesion: Formulations can be engineered for a wide spectrum of adhesion levels, from low-tack repositionable options to high-strength structural bonds.

●Broad Service Temperature: They maintain performance across a wider temperature range than rubber-based systems.

Table 1 – Typical Properties of Acrylic PSAs

| Property | Typical Value | Test Method / Notes |

| Peel Strength (N/25mm) | 8–12 | PSTC-101, stainless steel |

| Shear Strength (hours, 1kg load) | 500–1000 | PSTC-107 |

| Service Temperature Range (°C) | -30 to 150 | Continuous operation |

| UV Resistance | Excellent | 1000h UV exposure, ASTM G154 |

| Solvent Resistance | Good | Immersion in isopropanol, heptane, toluene |

Silicone Adhesives

Based on siloxane polymers, silicone adhesives are a specialty PSA class engineered for performance in demanding thermal environments.

●Extreme Temperature Operation: Their defining feature is an exceptionally wide operational temperature range, typically from -40°C to 260°C.

●Low Surface Energy (LSE) Substrate Bonding: They have a very low surface energy, which facilitates strong adhesion to difficult-to-bond LSE materials like silicones, polypropylenes, and certain coatings.

●Higher Associated Cost: These systems are more expensive than acrylic or rubber counterparts, which typically reserves their use for applications where their specific performance attributes are a requirement.

●Low Initial Adhesion: They exhibit a lower initial “grab” than other systems. This requires the application of firm and uniform pressure during assembly to achieve final bond strength.

Table 2 – Typical Properties of Silicone PSAs

| Property | Typical Value | Test Method / Notes |

| Peel Strength (N/25mm) | 6–9 | PSTC-101, stainless steel |

| Shear Strength (hours, 1kg load) | 300–700 | PSTC-107 |

| Service Temperature Range (°C) | -40 to 260 | Continuous operation |

| LSE Substrate Adhesion | Excellent | Polypropylene, PTFE, silicone rubber |

| Cost Index (relative) | 2.5–3× Acrylic | Based on equal coating weight |

Rubber-Based Adhesives

Formulated from natural or synthetic rubbers blended with tackifying resins, these adhesives are known for high initial adhesion and cost-effectiveness.

●High Initial Grab: They provide a high immediate tack, which allows for rapid bonding to many different surfaces upon contact.

●Economic Efficiency: They are generally the most economical PSA option for high-volume or cost-sensitive assemblies.

●Environmental Limitations: The polymer structure is susceptible to degradation from UV radiation, oxidation, and high temperatures. This restricts their use to controlled, indoor environments where long-term durability is not a primary design requirement.

●General Purpose Bonding: They adhere well to a broad range of common substrates, making them practical for general mounting and temporary attachment tasks.

Table 3 – Typical Properties of Rubber-Based PSAs

| Property | Typical Value | Test Method / Notes |

| Peel Strength (N/25mm) | 10–14 | PSTC-101, stainless steel |

| Shear Strength (hours, 1kg load) | 50–200 | PSTC-107 |

| Service Temperature Range (°C) | -10 to 80 | Continuous operation |

| UV Resistance | Poor | 250h UV exposure, ASTM G154 |

| Cost Index (relative) | 0.5–0.8× Acrylic | Based on equal coating weight |

Matching the PSA chemical system to the specific mechanical, environmental, and substrate requirements of an assembly is a fundamental aspect of successful product design.

Understanding the Anatomy of PSA Tapes

The physical construction of a PSA tape is as important as its chemical composition. Different formats are engineered to meet specific application requirements for handling, support, and conformability.

Transfer Tapes

A transfer tape is the simplest form of PSA, consisting of an unsupported film of adhesive coated onto a dual-sided release liner.

●Maximum Conformability: Lacking a carrier, these tapes are extremely flexible and ideal for laminating to irregular or curved surfaces.

●Thin Bond Lines: They can create very thin, uniform bonds, suitable for applications where minimal thickness is required.

●Applications: Commonly used for bonding FPC to curved enclosures, assembling membrane switches, and general graphic attachment.

Typical Properties of Transfer Tapes

| Property | Typical Value |

| Total Thickness (mm) | 0.05 – 0.13 |

| Carrier | None |

| Peel Strength (N/25mm) | 6 – 12 |

| Service Temperature Range (°C) | -30 to 150 |

| Conformability | Excellent |

Double-Coated Tapes

Double-coated tapes feature a carrier material, such as a PET film or non-woven tissue, coated on both sides with adhesive.

●Dimensional Stability: The carrier provides stability, making the tape easier to handle and apply, especially in automated processes.

●Added Strength: The carrier contributes mechanical strength to the bond line.

●Versatility: The combination of different carriers and adhesives allows for a vast range of products tailored to specific needs (e.g., foam carriers for gap-filling).

Typical Properties of Double-Coated Tapes

| Property | Typical Value |

| Total Thickness (mm) | 0.08 – 0.25 |

| Carrier Material | PET, Tissue, Foam |

| Peel Strength (N/25mm) | 8 – 14 |

| Service Temperature Range (°C) | -20 to 120 |

| Dimensional Stability | High |

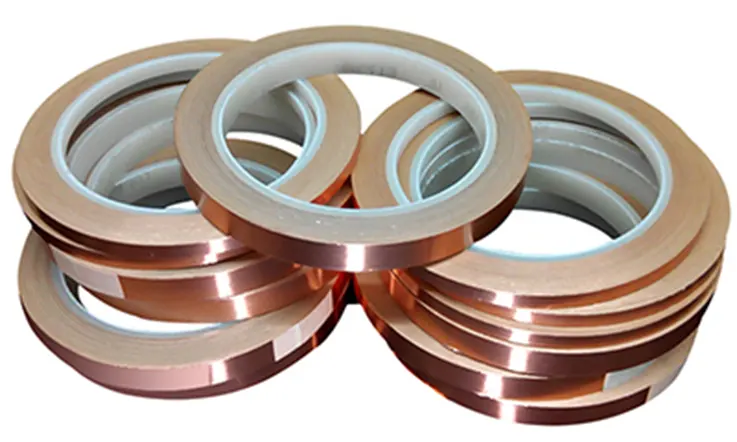

Single-Coated Tapes

A single-coated tape has an adhesive layer on one side of a carrier material, where the carrier itself often serves a functional purpose.

●Functional Carrier: The carrier can provide electrical insulation (Polyimide), EMI shielding (Copper Foil), thermal conductivity, or surface protection.

●Primary Use: Applications include high-temperature masking, surface protection during shipping, electrical insulation, and heat management.

Typical Properties of Single-Coated Tapes

| Property | Typical Value |

| Total Thickness (mm) | 0.05 – 0.1 (Polyimide) |

| Carrier Material | Polyimide, PET, Copper Foil |

| Adhesion (N/25mm) | 5 – 9 |

| Service Temperature Range (°C) | -40 to 260 (Polyimide) |

| Special Function | Insulation, EMI shielding |

Self-Wound Tapes

Self-wound tapes are constructed with an adhesive on one side of the carrier and a specialized release coating on the reverse side, eliminating the need for a separate release liner.

●Linerless Construction: This design simplifies dispensing.

●Common Applications: Primarily used for packaging, bundling, and general-purpose masking where high precision is not the main objective.

Typical Properties of Self-Wound Tapes

| Property | Typical Value |

| Total Thickness (mm) | 0.05 – 0.15 |

| Carrier Material | Paper, BOPP, PVC |

| Adhesion (N/25mm) | 4 – 8 |

| Service Temperature Range (°C) | -10 to 80 |

| Release Coating Type | Silicone or Fluoropolymer |

Carrier Materials in Double-Coated Adhesive Tapes

In double-coated tapes, the carrier material governs the tape’s mechanical behavior, handling characteristics during assembly, and overall application suitability.

Polyester (PET) Film

PET film is a frequently selected carrier, offering a favorable balance of performance and cost.

●High Dimensional Stability: The material resists stretching and shrinking. This stability is beneficial for operations requiring precise die-cutting and automated placement.

●Mechanical and Thermal Resistance: It provides high tensile strength and good resistance to moderate heat and various chemicals.

●Smooth and Uniform Surface: The smooth carrier surface helps create a uniform bond line between substrates.

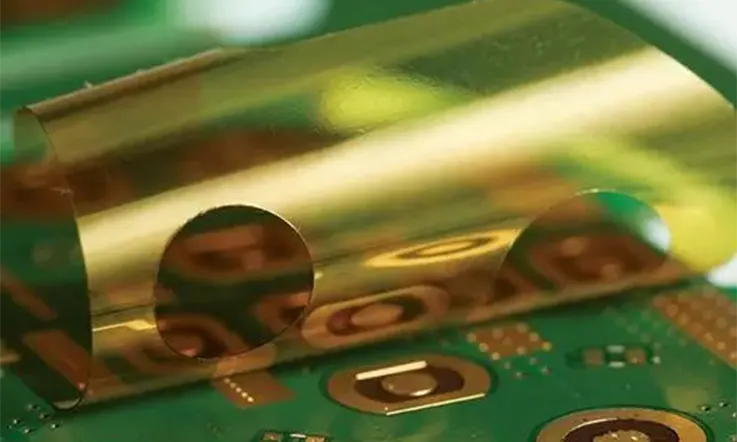

Polyimide (PI) Film for High-Temperature Processing

Polyimide film is the carrier of choice for applications involving exposure to high-temperature processes.

●Extreme Thermal Stability: It maintains its physical and chemical properties at continuous operating temperatures that can exceed 260°C.

●Application in Soldering Masking: This attribute allows its use as a carrier for masking tapes in PCB assembly. The tape can withstand wave soldering and reflow oven thermal profiles without degrading, shrinking, or leaving adhesive residue, thereby protecting designated keep-out zones on the circuit board.

Foam Carriers (Urethane and Acrylic)

Foam carriers offer conformability and gap-filling capabilities that exceed those of solid film carriers.

●Effective Gap-Filling: The compressible structure enables the bonding of textured, irregular, or mismatched surfaces.

●Vibration Damping and Shock Absorption: These carriers are effective for dissipating shock and damping vibration, which can help protect sensitive components and enhance the operational lifespan of a device.

Non-Woven Tissue Carriers

Constructed from a web of entangled fibers, non-woven tissue carriers are flexible and highly conformable.

●High Conformability to Irregular Shapes: The material readily conforms to curved and non-uniform surfaces.

●Bonding on Textured Substrates: Its pliable nature enables fuller adhesive contact on rough or textured materials, improving bond integrity.

The Function of Release Liners in Tape Processing and Application

While discarded after use, the release liner is a functional component engineered to protect the adhesive and facilitate precise handling, die-cutting, and automated application of PSA tapes.

Liner Materials and Their Process Suitability

The liner material choice affects handling characteristics and performance during converting and assembly processes.

●Densified Kraft (DK) Paper: An economical option generally used for applications involving flat-sheet formats and manual processing.

●Polycoated Kraft (PCK) Paper: A polyethylene coating adds moisture stability and surface smoothness, making this paper type suitable for more precise die-cutting operations.

●PET Film Liners: This film offers high dimensional stability and tensile strength. These characteristics prevent tearing during high-speed automated dispensing and ensure accurate registration, leading to higher process yields. Its ultra-smooth surface is also a requirement for optical-grade adhesives.

Release Coatings and Differential Release Systems

Most release liners are coated with a silicone-based agent to create a non-stick surface with specific release characteristics.

●Controlled Release Force: The formulation of the silicone coating can be adjusted to engineer a specific release force, ranging from easy-peel to tight-release.

●Differential Release for Assembly Efficiency: Double-coated tapes can be designed with a different release value on each liner. This feature dictates the order of removal, ensuring one adhesive face is exposed while the other remains protected. This planned functionality simplifies handling, reduces errors in complex assemblies, and improves the speed of both manual and automated processes.

A Framework for PSA Selection in Electronic Assemblies

Selecting the appropriate PSA involves a systematic evaluation of an application’s mechanical, thermal, electrical, and substrate-related requirements. This process ensures long-term bond reliability and manufacturability.

Substrate Compatibility and Surface Characteristics

An adhesive’s ability to wet out and bond to a substrate is governed by the surface energy of that material.

●High Surface Energy (HSE) Substrates: Materials such as metals, glass, and bare FR-4 generally permit strong adhesive bonds.

●Low Surface Energy (LSE) Substrates: Materials like polypropylene, polyethylene, and certain powder-coated finishes present bonding challenges and typically require specially formulated LSE adhesives.

●Surface Preparation: For dependable adhesion, all bonding surfaces must be clean and free of oils, dust, or other contaminants. This is a standard pre-application step in any quality-controlled assembly process.

Typical Surface Energy of Common Substrates

| Material / Substrate | Surface Energy (dyn/cm) | Bonding Difficulty |

| Stainless Steel | 700–1100 | Easy |

| Glass | 900–1100 | Easy |

| FR-4 (bare) | 650–850 | Easy |

| Polypropylene (PP) | 29–31 | Difficult – LSE adhesive required |

| Polyethylene (PE) | 31–33 | Difficult – LSE adhesive required |

| Powder-Coated Steel | 35–45 | Moderate – surface prep recommended |

Analysis of Thermal Operating Conditions

The selected PSA must maintain its functional properties across the device’s full operational temperature range.

●Service Temperature Range: The evaluation must account for both continuous operating temperatures and intermittent thermal spikes from sources like processors or power components.

●Glass Transition Temperature (Tg): This thermal property marks the temperature at which the adhesive transitions from a more rigid, glassy state to a softer, more pliable state. Exceeding the Tg can alter mechanical properties like shear strength and creep resistance.

Typical Thermal Properties of PSA Types

| PSA Type | Service Temp Range (°C) | Tg (°C) |

| Acrylic | -30 to 150 | -20 to +15 |

| Silicone | -40 to 260 | -60 to -40 |

| Rubber-Based | -10 to 80 | -40 to -10 |

Assessment of Mechanical Stress and Load Profile

An assessment of the types and magnitudes of mechanical stress that the bond will encounter is a foundation of the selection process.

●Shear Resistance: The adhesive’s ability to resist forces acting parallel to the bond line.

●Tensile Strength: The adhesive’s capacity to withstand forces pulling perpendicularly away from the bond line.

●Peel Adhesion: The adhesive’s resistance to a stripping force concentrated along the edge of the bond line, a common stress in flexible assemblies.

Typical Mechanical Performance of PSA Types

| PSA Type | Shear Strength (hours, 1kg) | Tensile Strength (MPa) | 180° Peel (N/25mm) |

| Acrylic | 500–1000 | 0.6–1.0 | 8–12 |

| Silicone | 300–700 | 0.4–0.7 | 6–9 |

| Rubber-Based | 50–200 | 0.5–0.8 | 10–14 |

Determination of Electrical Property Needs

In certain electronic designs, the PSA may need to perform a specific electrical function in addition to its bonding role.

●Electrical Insulation: The majority of standard PSAs are dielectrics, which serve to prevent electrical shorts between conductive layers or components.

●Electrical Conductivity: For applications like EMI/RFI shielding or establishing grounding points, specialized PSAs filled with conductive particles (such as nickel/copper or silver) are available.

Functional PSA Systems for Advanced Assemblies

Beyond structural bonding, PSA systems are engineered with specific properties to solve complex challenges in modern electronic devices.

Optically Clear Adhesives (OCAs)

OCAs are a high-performance class of acrylic PSAs developed for applications where optical integrity is a primary requirement, such as in touch panels and display modules.

●High Light Transmittance: Formulations typically feature a light transmittance greater than 99%, which supports maximum display brightness and vibrancy.

●Matched Refractive Index: The adhesive’s refractive index is matched to the adjacent optical layers, minimizing internal light scattering to improve display contrast and readability in various lighting conditions.

●Primary Application: Used for laminating the layers of a display stack, including cover glass, touch sensors, and display panels. This process requires precise, particle-free application to prevent bubbles and defects in the optical path.

Thermally Conductive PSAs

Functioning as thermal interface materials, these PSAs create an efficient pathway to dissipate heat away from electronic components.

●Filler Materials: A dielectric adhesive matrix is filled with thermally conductive ceramic particles, such as aluminum oxide or boron nitride, to facilitate heat transfer.

●Heat Management Applications: They are used to bond heat-generating components (e.g., processors, power ICs, LEDs) to heat sinks or a chassis. This helps to efficiently transfer thermal energy, thereby preventing performance throttling and enhancing component longevity.

Electrically Conductive PSAs

These specialized PSAs are formulated to provide a reliable electrical connection between bonded substrates.

●Filler Materials: The adhesive matrix is impregnated with conductive particles, including silver, nickel-coated spheres, or carbon fibers.

●Grounding and Shielding: These materials create a conductive path for grounding applications or for shielding sensitive components from electromagnetic interference (EMI) and radio-frequency interference (RFI).

Process Control and Integration for PSA Applications in PCB Assembly

The effective use of PSAs within a PCB assembly workflow is governed by stringent process controls for converting, placement, and handling.

Stiffener Bonding Process for Flexible Circuits

In FPC assemblies, stiffeners (typically FR-4 or polyimide) are bonded to specific locations, such as ZIF connector areas, to provide localized mechanical reinforcement.

●Lamination and Fabrication Sequence: The standard procedure involves laminating the PSA to the stiffener material before the stiffener is die-cut or laser-cut to its final profile.

●Placement and Registration: Alignment is achieved by positioning the stiffener assembly to designated silkscreen outlines on the flexible circuit, ensuring proper registration with the circuit features.

SMT Process Compatibility and Sequencing

The high temperatures associated with lead-free SMT reflow profiles (often peaking near 260°C) demand careful material selection and process sequencing for any applied PSAs.

●High-Temperature PSA Selection: While a limited number of specialty PSAs are engineered to withstand SMT reflow temperatures, their application is reserved for specific design cases.

●Post-Reflow Application Strategy: For most applications, the recommended and most common strategy is to bond the PSA components after all soldering processes are complete. This sequencing preserves the adhesive’s specified performance and reliability by avoiding any exposure to thermal extremes.

Converting Methods: Die-Cutting vs. Laser Cutting

The method for converting PSA tape into custom shapes is selected based on volume, design complexity, and cost objectives.

●Die-Cutting: This method employs a steel rule die to stamp parts from tape. It is highly efficient and cost-effective for high-volume runs of stable designs where tooling investment is justified.

●Laser Cutting: This process uses a directed laser beam to cut parts. It provides high precision for intricate geometries and is ideal for prototyping or low-volume runs, as it requires no physical tooling and allows for rapid design adjustments.

Comparative Overview: PSAs vs. Thermoset Adhesives

In electronics assembly, both PSAs and thermoset adhesives are utilized for bonding. The selection between these two systems is determined by the specific requirements of the application, involving a trade-off among assembly speed, ultimate bond strength, and operational demands.

Pressure-Sensitive Adhesives (PSAs)

●Bonding Mechanism: Forms a viscoelastic, physical bond upon the application of pressure. No curing cycle is needed.

●Performance Profile: Offers good flexibility and stress-damping properties. Certain formulations can be removed or repositioned.

●Application Process: A simple, room-temperature application process that involves positioning and applying pressure, suitable for high-speed automated assembly.

●Reworkability: Many PSAs allow for components to be reworked, adjusted, or removed, which can be advantageous during prototyping or repair.

Thermoset Adhesives

●Bonding Mechanism: Forms a rigid, permanent chemical bond (cross-linking) through a curing process initiated by heat, light, or a chemical agent.

●Performance Profile: Generally provides higher ultimate bond strength, structural rigidity, and superior resistance to high temperatures and harsh chemicals.

●Application Process: Typically involves dispensing a liquid or paste adhesive, followed by a dedicated curing cycle which adds time and thermal load to the manufacturing process.

●Reworkability: Bonds are typically permanent and cannot be reworked without potentially damaging the components or substrate.

The optimal bonding solution is identified through a holistic review of the product’s design specifications, manufacturing process, and intended service environment.

A Guide to Diagnosing and Resolving Bond Failures

Analyzing bond failure modes is a methodical process used to validate and optimize an assembly process, thereby ensuring final product reliability.

Adhesive Failure (Interfacial)

This failure mode occurs when the adhesive separates cleanly from one of the substrate surfaces, indicating an issue at the bonding interface.

●Primary Causes: Insufficient wetting of the adhesive on a low surface energy (LSE) substrate, or the presence of surface contaminants such as oils, dust, or moisture.

●Corrective Actions: Implement or enhance surface preparation as a controlled process step (e.g., cleaning with appropriate solvents, plasma treatment). Alternatively, select a PSA formulation specifically engineered for LSE materials.

Cohesive Failure

This mode is characterized by the adhesive splitting internally, leaving adhesive residue on both bonded substrates.

●Primary Cause: The load applied to the joint, whether from shear, tensile, or peel forces, surpassed the internal strength (cohesion) of the adhesive material itself.

●Corrective Action: Select a PSA formulation with higher cohesive strength (internal strength), such as a more highly cross-linked acrylic adhesive, to meet the mechanical demands of the application.

Substrate Failure

This outcome occurs when the adhesive bond itself remains intact while one of the bonded substrates delaminates or fractures. Technically, this represents a successful, robust adhesive bond.

●Interpretation: The adhesive’s interfacial bond strength and its own internal cohesive strength are both greater than the internal strength of the substrate material.

●Analysis: This is not an adhesive failure mode. The result indicates that the selected adhesive meets or exceeds the application’s bonding requirements. If substrate damage is undesirable, the analysis may shift to either reinforcing the substrate or selecting an adhesive with a lower peel adhesion value that still meets the necessary performance criteria.

Adhesive Compliance with Electronics Industry Standards

Adhesives selected for electronic products are subject to rigorous environmental and safety regulations. Adherence to these standards is a prerequisite for market access in many global regions and a fundamental component of responsible manufacturing.

RoHS (Restriction of Hazardous Substances)

●Objective: This directive restricts the use of specified hazardous materials, including lead, mercury, and cadmium, within electronic and electrical equipment.

●Compliance Requirement: All PSA materials selected for use in an assembly must be accompanied by supplier certification of RoHS compliance to ensure the final product adheres to these standards.

REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals)

●Objective: This European Union regulation governs the production and use of chemical substances to protect human health and the environment.

●Compliance Requirement: Material suppliers are obligated to provide declarations regarding the presence of any Substances of Very High Concern (SVHCs). This supply chain transparency allows for informed material selection and accurate regulatory reporting for the final product.

UL (Underwriters Laboratories) Recognition

●Objective: UL is a global organization that provides safety testing and certification. The UL 94 standard is a widely recognized vertical burn test for assessing the flammability of plastic materials.

●Compliance Requirement: For PSAs used within enclosures, particularly near power supplies or high-voltage areas, a UL 94 V-0 flammability rating is frequently specified. This contributes to the overall fire safety of the end device by ensuring the material will self-extinguish and not propagate a flame.

Future Directions in Adhesive Technology for Electronics

The science of adhesives continues to evolve, with ongoing developments aimed at addressing the next generation of electronic design and manufacturing challenges. Notable directions include:

●Reworkable and Debondable Adhesives: Development of materials that can be debonded on command through a specific trigger (e.g., heat, light). This technology supports high-value component recovery, device repair, and circular economy initiatives.

●Sustainable and Bio-Based Formulations: Research into adhesives derived from renewable, bio-based resources to reduce environmental impact and meet growing demands for sustainable manufacturing practices.

●Multi-Functional “Smart” Adhesives: The integration of additional functionalities directly into the adhesive. This includes materials that can provide integrated sensing, dynamic thermal management, or self-healing properties to enhance device performance and longevity.

From chemical systems and carrier materials to process integration, regulatory compliance, and failure analysis, the selection and application of a PSA is a multi-faceted engineering decision. It requires a deep, integrated understanding of materials science and manufacturing processes. Navigating this complexity to achieve a reliable and manufacturable final product underscores the value of deep domain expertise.

Application Case Studies: Theory in Practice

This section presents real-world examples of how the principles discussed in this guide are applied to solve complex engineering challenges. These cases illustrate the practical application of PSA technology in demanding electronic designs.

Case Study 1: Biocompatible Adhesive for a Wearable Medical Sensor

●Challenge: A project for a wearable biometric monitor required bonding a flexible sensor to its skin-contact housing. The bonding agent needed to be biocompatible, waterproof, and capable of resisting sweat and skin oils while enduring constant motion.

●Solution: An engineered solution was developed using a medical-grade acrylic PSA on a thin, conformable polyurethane carrier. This material combination successfully passed ISO 10993 biocompatibility testing and provided robust adhesion to both the LSE plastic housing and skin. Precision laser cutting was employed to fabricate the intricate part geometry.

●Outcome: The final bond remained secure throughout rigorous simulated wear and environmental cycling tests, contributing to reliable sensor readings and patient comfort.

Case Study 2: Thermal Management for High-Power LED Lighting

●Challenge:In an industrial lighting application, premature LED failures occurred due to overheating. The current mechanical fastening method led to variable thermal contact between the metal-core PCB and the primary heat sink.

●Solution: The mechanical fasteners were replaced with a thermally conductive acrylic PSA tape. This approach provided a strong structural bond while creating a thin, uniform thermal interface that eliminated insulating air gaps.

●Outcome: The revised assembly process lowered the average LED operating temperature by 15°C, which extended the product’s operational lifespan and reliability. This change also simplified and accelerated the manufacturing workflow.

Case Study 3: ZIF Connector Stiffener on a Rigid-Flex Board

●Challenge: A robotics application required the addition of a rigid FR-4 stiffener under a ZIF connector to endure thousands of flex-cable insertion cycles. The stiffener’s location in a central area of the circuit precluded the use of a co-laminated thermoset adhesive during fabrication.

●Solution: A high-strength acrylic transfer tape (3M 467MP) was specified for its proven performance in high-stress applications. The FR-4 stiffener was pre-laminated with the PSA and then precision-routed. A clear placement outline on the FPC’s silkscreen layer guided accurate manual application of the stiffener after the SMT reflow process was complete.

●Outcome: The PSA created a permanent, high-peel-strength bond that fulfilled the demanding mechanical durability requirements without disrupting the primary PCB fabrication and assembly workflow.

Frequently Asked Questions (FAQ)

1.What is the difference between tack, adhesion, and cohesion?

● Tack is the initial “stickiness” of the adhesive upon light contact. Adhesion is the ultimate bond strength between the adhesive and the substrate. Cohesion is the internal strength of the adhesive itself.

2.How long does it take for a PSA to fully bond?

● Most PSAs achieve about 80% of their final bond strength within the first 24 hours. They typically reach 100% strength after a “dwell time” of 48 to 72 hours at room temperature.

3.How should I prepare a surface for PSA application?

● The surface must be clean, dry, and free of contaminants. The most common method is to wipe the surface with a 50/50 mixture of isopropyl alcohol (IPA) and water using a lint-free cloth.

4.Can I remove or reposition a PSA tape after application?

● It depends on the adhesive. Some are designed for permanent bonds and are very difficult to remove. Others, especially those with lower initial tack, may allow for brief repositioning immediately after application. Specialty “removable” adhesives are designed to be removed cleanly.

5.What is the typical shelf life of a PSA tape?

● Most PSA tapes have a shelf life of 12 to 24 months when stored in a cool, dry place away from direct sunlight, typically at around 21°C (70°F) and 50% relative humidity.

A Foundation of Manufacturing Excellence

The technical depth presented in this guide is the same depth that underpins the manufacturing operations. The selection of a PCB supplier is a selection of capability—a capability engineered to deliver precision, reliability, and value for the most demanding projects.

End-to-End Integrated Solutions

A true one-stop solution is offered for circuitry needs, with capabilities extending from initial DFM (Design for Manufacturability) analysis and material selection to final assembly and testing.

●Integrated Workflow: Projects are managed seamlessly from raw PCB fabrication, through component sourcing, to SMT and through-hole assembly, all within a single, unified facility.

●Streamlined Communication: A single point of contact for the entire project simplifies logistics and ensures clear, direct communication.

●Accelerated Time-to-Market: By eliminating the need to coordinate between multiple vendors, project timelines are substantially shortened.

Advanced Materials Expertise

Proficiency extends far beyond standard FR-4 to include extensive experience in handling a wide array of advanced materials for modern electronics.

●Diverse Substrate Processing: Demonstrated expertise in processing high-frequency materials (e.g., Rogers, Teflon), high-temperature polyimide (PI) for flexible circuits, and various metal-core PCBs (MCPCB).

●Adhesive and Bonding Acumen: A deep, practical understanding of various bonding agents, including the full spectrum of PSAs and thermoset adhesives detailed in this guide. This ensures the optimal material is selected for each specific application.

Precision Fabrication Technologies

State-of-the-art equipment is utilized to meet the miniaturization and complexity demands of next-generation products.

●High-Density Interconnect (HDI): Utilization of laser drilling for microvias and advanced lamination processes to build complex, high-density boards.

●Fine Line Circuitry: Laser Direct Imaging (LDI) technology delivers superior trace and space resolution, enabling more compact and intricate circuit designs.

●Automated Inspection: Full implementation of Automated Optical Inspection (AOI) and Automated X-ray Inspection (AXI) for BGA and complex packages to verify assembly quality.

Rigorous Quality Assurance Systems

A dedication to quality is validated by internationally recognized standards and embedded in every step of the process.

●Adherence to International Standards: Maintenance of ISO 9001, IATF 16949 (automotive quality management), and ISO 13485 (medical devices) certifications.

●In-Process Quality Control: Implementation of Statistical Process Control (SPC), Time-Domain Reflectometry (TDR) for impedance testing, and cross-section analysis to monitor and verify quality throughout the fabrication cycle.

●Full Material and Process Traceability: Robust systems are in place to allow for complete traceability of all materials and processes used in the creation of a product.

Flexible Production Scalability

The operational structure is designed to support projects throughout the entire lifecycle, from initial concept to mass production.

●Rapid Prototyping: Dedicated quick-turn prototyping lines to facilitate rapid design validation.

●Low-to-Mid Volume Production: Flexible manufacturing cells are configured to efficiently handle smaller and more diverse production runs.

●High-Volume Capability: Fully automated lines are available to deliver cost-effective, high-volume manufacturing while maintaining stringent quality standards.

Related Posts:

1. Selecting PCB Laminate Materials: A Comprehensive Overview

2. PCB Copper Trace Width and Space: Everything You Need to Know About Them

3. Which Types are Most Commonly Used in PCB Substrates?

4. What Is Fiberglass PCB and Why Fiberglass Used in PCB Manufacturing?

5. Standard PCB Thickness-Choosing the Correct Thickness for PCB