Copper Clad Laminate (CCL) is a crucial material used in the fabrication of electronic circuitry and Printed Circuit Boards (PCBs), finding widespread application across various industries including consumer electronics, mobile communication, computers, avionics, and military hardware. As a foundational component of the PCB industry, the CCL manufacturing sector is continuously evolving due to advancements in mobile communication technology, semiconductor manufacturing, surface mounting technology, and PCB manufacturing technology, particularly in China and Southeast Asia. In light of these developments, the CCL manufacturing industry is expanding with promising prospects for growth, particularly in China.

What Is Copper-clad Laminate (CCL) ?

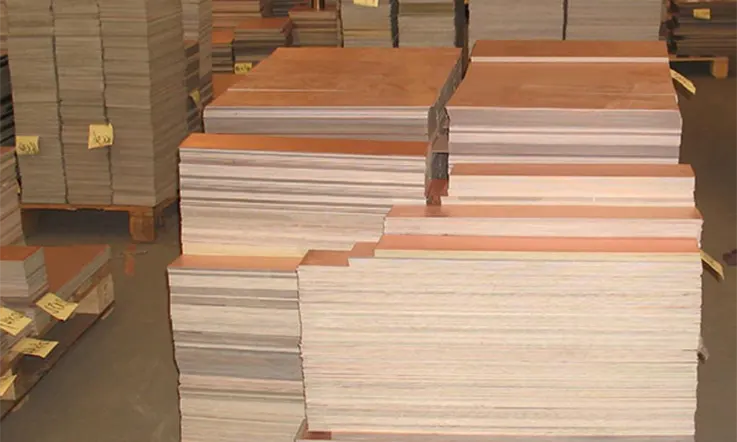

CCL, also known as Copper Clad Laminate, is a vital component of PCB fabrication. It is comprised of reinforcing materials, such as glass fabric, fiber paper, and glass fiber paper, that are impregnated with epoxy resin through a process of soaking and subsequent baking to produce prepreg. The resulting material is then cut, laminated, and copper-coated at high temperatures, pressures, and vacuums.

CCL serves as a versatile, multi-functional composite material that performs several critical functions for PCBs, such as providing conductivity, insulation, mechanical support, and signal transmission. As such, it is a critical factor that impacts PCB performance, quality, fabrication level, fabrication cost, and long-term reliability.

Due to the continuously evolving demands of the market and the ongoing development of PCB technology, there is a growing need for CCL to meet new technological requirements. This need serves as both a driving force for the technological advancement of CCL and the development of fabrication processes.

Copper Clad Laminate (CCL) Materials

● Copper Foil: Copper foil is a type of cathodic electrolytic substance that serves as a thin and continuous layer of metal foil that is applied to the base of a PCB. Its ability to easily bond with insulating layers allows the creation of a printed protective layer and a corrosion-resistant board pattern.

Copper foil plays a crucial role in the overall performance and reliability of the PCB. Its uniformity, thickness, and adhesion to the base material are critical factors that determine the quality and durability of the final product.

As a result, due to its excellent electrical conductivity, ease of bonding, and resistance to corrosion, copper foil is a highly beneficial material in the creation of high-quality PCBs. Its use helps to ensure the longevity and reliability of electronic devices and systems.

● Prepreg: Prepregs, short for pre-impregnated fiberglass, are sheets of fiberglass that have already been impregnated with resin. The resin is pre-dried to ensure it flows, sticks, and completely immerses during the heating process without hardening. Prepregs are similar to FR4 material as they have an adhesive coating laminated on top of them.

Prepregs are available in various thicknesses and the amount of resin they contain determines their variants, which include SR (Standard Resin), MR (Medium Resin), and HR (High Resin). Material quality is of utmost importance to achieve the desired final thickness, layer structure, or impedance. Hence, the thicknesses provided serve as examples.

The unique application and performance requirements of the PCB dictate the type and combination of materials used in CCLs. These criteria can vary significantly. For instance, some CCLs are constructed using multiple layers of copper and dielectric material, while others may feature additional metal layers or special coatings to enhance their performance.

Copper Clad Laminates: Types

Stiff organic resin copper clad laminates (CCLs) have been the primary choice for manufacturing printed circuit boards (PCBs) to date. This category includes paper substrates, glass fiber substrates, and composite substrates. Additionally, rigid CCLs can be further characterized based on substrates such as BUM (build-up multilayer) substrate, metal substrate, ceramic substrate, thermoplastic substrate, capacitor embedded substrate, and others. Flexible CCLs, on the other hand, are typically classified into polyester base film flexible CCL, polyimide base film flexible CCL, LCP (liquid crystal polymer) base flexible CCL, and similar products.

Consequently, based on their mechanical rigidity, copper clad laminates for PCB construction are categorized into two major types: rigid copper-clad laminates and flexible copper-clad laminates.

● Rigid Copper Clad Laminate: Copper clad laminates (CCLs) can be divided into three types based on the insulating materials and division structures used: metal-core copper laminate, ceramic base copper-clad laminate, or organic resin copper clad laminate. When considering thickness, CCLs can either be normal copper-clad laminates or thin copper-clad laminates.

● Reinforcement materials such as paper base, electronic fiberglass cloth-based, and composite base are utilized in CCL manufacturing. Depending on the type of insulating resin employed, CCLs may be polyester resin copper-clad laminates, epoxy resin copper-clad laminates, or cyanate resin copper-clad laminates.

● Flex Copper Clad Laminate: Flexible copper clad laminates (CCLs) consist of three components- copper foil, insulating film, and inter-layer glue. The insulating film used in flexible CCLs is available in two categories- polyester film and polyimide film, which can be flame retardant or non-flame retardant.

The insulating film can also be made of thin electronic fiberglass cloth copper-clad laminates and flame retardant or non-flame retardant polyester.

Nowadays, a broad range of CCLs is utilized in printed circuit board (PCB) production, with thicknesses typically ranging between 0.05 and 3.2 millimeters. Therefore, manufacturers can custom order an array of PCBs, including rigid PCBs, flexible PCBs, rigid-flex PCBs, high-frequency PCBs, ceramic PCBs, high-TG PCBs, aluminum PCBs, halogen-free PCBs, lead-free PCBs, thick-copper PCBs, carbon ink PCBs, and carbon nanotube PCBs from JarnisTech.

If you need assistance with material selection for your PCBs, please contact us at sales at JarnisTech.com, or you can use our website to get in touch with us.

Advantages of PCB Copper Clad Laminates

PCB Copper Clad Laminates (CCLs) have several advantages that make them the material of choice for the majority of printed circuit board designs.

● Good Thermal Conductivity: Copper is known to exhibit excellent thermal conductivity, which is essential in dissipating heat generated during PCB operation. The high thermal conductivity of copper is a significant advantage of CCLs, making them effective in thermal management.

● High Level of Mechanical Strength: CCLs are composed primarily of materials with high mechanical strength, including copper and fiberglass or other reinforcing materials. This construction gives them impressive mechanical strength, which is a key requirement for PCBs that are subjected to stress and environmental factors.

● Enhanced Durability: Copper is known for its exceptional corrosion resistance, which is why CCLs offer excellent durability, even in extreme or harsh environments. They resist the effects of corrosion, oxidation, and moisture ingress, ensuring long-lasting and optimal performance.

● High Electrical Conductivity: CCLs have a high electrical conductivity, which is a significant advantage in ensuring good signal integrity and providing low impedance connections between components on the board. This feature is especially crucial in high-speed PCB designs that require low loss and good signal integrity.

● Versatility: CCLs are available in a wide range of sizes, thicknesses, and material constructions, allowing for customization to suit different design requirements. They can be tailored to meet specific needs, making them versatile and compatible with various PCB design applications.

Therefore, CCLs provide high thermal conductivity, mechanical strength, durability, electrical conductivity, and versatility. These key advantages position CCLs as a leading choice in printed circuit board design and manufacture.

Manufacturing Process of Rigid PCB Copper Clad Laminates

The manufacturing process of rigid PCB copper clad laminates typically involves the following steps:

● Pre-Treatment: The base material (usually fiberglass or a similar substrate) is cleaned and treated to remove any contaminants that could compromise the bonding between the copper and the substrate.

● Coating: The substrate is coated with an adhesive material that will bond the copper to the substrate. The adhesive material is typically a resin-based material that is cured through a heat or chemical process.

● Lamination: The treated substrate is then laminated with a sheet of copper foil using heat and pressure. The sheets of copper foil may be bonded to one or both sides of the substrate, depending on the design requirements.

● Etching: The copper-clad substrate is then masked, and unwanted copper is chemically etched away from the surface using an acid solution. The etching process leaves behind the copper traces and pads for the circuit board.

● Drilling: Holes are drilled through the substrate and copper layers to allow for the insertion of components into the circuit board.

● Plating: The holes are plated with a conductive material (such as copper) to create vias and to provide electrical connections between the different layers of the circuit board.

● Final Finishing: The final steps of the manufacturing process may include coating the surface with a protective layer or applying a solder mask as per the design requirements.

Once completed, the rigid PCB copper clad laminate is ready for testing, inspection, and assembly into a final product.

Common Use Copper-Clad Laminate In Rigid PCB Manufacturing

Copper Core Copper Clad Laminates

Copper Core CCL, much like Aluminum Core CCL, consists of copper plate, dielectric bonding layer, and copper foil. The thermal conductivity of the board is primarily determined by the bonding dielectric layer and whether or not the board has a thermal dissipation design.

Copper Core PCB, also known as copper substrate PCB, copper-based PCB, or copper-clad PCB, is a type of printed circuit board that has three main design types:

● Chip on Board (COB) copper PCB.

● Direct thermal path copper-based PCB (no insulator under the thermal path pad).

● Common copper core PCB, which has the circuitry on the copper layer and no PTH.

Copper Core CCL:Properties

The following are some of the key features of a copper-based CCL:

● Halogen-free.

● High UL Rated Flammability: 94V-0.

● Copper (Cu) Style: C1100 (386 W/m·K).

● Dielectric Constant (Dk or Er) (@1MHz): 4.8.

● Copper thickness available from 0.5oz to 4oz.

● Compatible with standard and lead-free assembly.

● Thermal Conductivity: 3.0W/m·K, 5.0W/m·K, 7.0W/m·K.

● Copper Core CCL thickness available from 0.8mm to 2.0mm.

● Glass Transition Temperature (Tg): Tg100oC, Tg120oC, Tg130oC.

These features are essential for ensuring high-quality and efficient printed circuit board (PCB) production. We offer copper-based CCLs with these specifications to meet the needs and preferences of our customers. Feel free to contact us or visit our website to learn more about our products and services.

FR-4 Copper Clad Laminates

FR-4 CCL is an essential rigid printed circuit board (PCB) substrate material that features copper cladding on one or both sides of the FR-4 substrate. These laminates can be used for single or double-sided PCB applications. FR-4 is a self-extinguishing material made up of woven glass fiber fabric and an epoxy resin laminate substance known as Flame Retardant-4.

As a manufacturer of high-quality PCB materials, we understand the importance of using the right substrate material to achieve optimal PCB performance. That’s why our FR-4 CCLs are designed to meet strict industry standards for flame resistance, electrical performance, and durability.

Properties of FR-4 CCL

FR-4 CCL is a high-performance substrate material essential for producing reliable and efficient printed circuit boards (PCBs). We take pride in offering FR-4 CCL products with the following key features:

● Halogen-free.

● Low CTE of 2.5%-3.8%.

● Copper thickness from 0.33oz to 6oz.

● High UL-Rated Flammability of 94V-0.

● Dissipation factor (Df) of 0.016 (@1GHz).

● Dielectric Constant of (Dk or Er) 3.66-4.5 (@1GHz).

● Compatible with zero-lead and standard assembly.

● FR4 CCL thickness from 0.2mm to 3.2mm is available.

● High Comparative Tracking Index (CTI) of at least 600V.

● High Temperature of Decomposition (Td) greater than 345°C.

● High, Mid, and Low Glass Transition Temperature of Tg150°C, Tg170°C, and Tg130°C to Tg140°C respectively.

At JarnisTech, we are committed to providing our customers with superior quality FR-4 CCLs that meet the most stringent industry standards. Contact us or visit our website to learn more about our products and how we can assist you in meeting your PCB material needs.

Aluminum Core Copper Clad Laminates

Aluminum (Alu) core or base copper clad laminates (CCLs) are manufactured by combining copper foil, aluminum plate, and a dielectric bonding layer under high pressure and temperature. The conductivity of the resulting aluminum core laminate is primarily determined by the dielectric bonding layer, while the metallic layers exhibit high thermal conductivity. Ceramic is often used as a dielectric material due to its excellent heat conductivity.

One-sided CCLs are typically used to create most aluminum PCBs, while double-sided CCLs are used to produce Alu PCBs with double layers.

Multi-layer hybrid Alu PCBs can also be produced using a combination of different CCLs. As a leading manufacturer of PCB materials, we offer high-quality aluminum core or base CCLs suited to meet the needs of various PCB applications.

Aluminum Core CCL: Properties

Aluminum core copper clad laminates (CCLs) are designed to achieve high-quality and reliable printed circuit board (PCB) performance. And the aluminum core CCLs feature the following key specifications:

● Halogen-free.

● High UL-Rated Flammability: 94V-0.

● Copper (Cu) Style: C1100 (386 W/m·K).

● Dielectric Constant (Dk or Er) of 4.8 @1MHz.

● Copper thickness available from 0.5oz to 6oz.

● Compatible with zero-lead and standard assembly.

● Aluminum Core CCL thickness from 0.8mm to 2.0mm is available.

● Glass Transition Temperature (Tg): Tg130°C, Tg120°C, and Tg100°C.

● Aluminum (Al) Alloy Style: 5052 (220 W/m·K) and 1060 (138 W/m·K).

● Thermal conductivity: 7.0W/m·K, 5.0W/m·K, 4.2W/m·K, 3.0W/m·K, 2.0W/m·K, 1.5W/m·K, and 1.0W/m·K.

As a leading PCB manufacturer of high-quality PCB materials, we take pride in our ability to offer aluminum core CCLs designed to meet stringent industry standards.

Microwave PCB/Radio Frequency (RF) PCB CCL

The characteristics that define the performance of copper clad laminates (CCLs) and prepregs (PPs) for microwave/RF printed circuit boards are critical for achieving optimal PCB performance. These characteristics include the dielectric constant (Dk), dissipation factor (Df), coefficient of thermal expansion (CTE), thermal coefficient of dielectric constant (TCDR), and thermal conductivity, which are all fundamental factors in designing PCB boards that operate at microwave frequencies.

Among the high-frequency materials available, poltetrafluoroethylene (PTFE) is a popular choice due to its excellent dielectric properties at microwave frequencies. As an established PCB material supplier, we have years of experience working with PTFE and other high-frequency materials. However, knowing the characteristics of each material is vital as they can react differently to various procedures.

Several key material suppliers specialize in producing high-frequency materials using copper clad laminates. These firms include: (insert names of key material suppliers). We work closely with these suppliers and have extensive knowledge of their products’ strengths and weaknesses.

There are four firms that create high-frequency materials using copper clad laminate, and they are as follows:

1. Taconic Dielectric Laminates

For over six decades, Taconic has been a leading industry pioneer in producing PTFE products. With a wide range of PTFE and silicon coated textiles, tapes and laminates, Taconic products are specifically designed for use in high-performance applications. In particular, Taconic materials are highly sought after in the production of RF and microwave printed circuit boards due to their outstanding thermal stability, low Dk values, and low Z-axis coefficients of thermal expansion (CTE).

One of the significant advantages of Taconic products is their ultra-low fiberglass content, which provides them with exceptional insertion loss capabilities and a consistent dielectric constant across the laminate, making them stand out from the competition. The laminates exhibit extraordinarily minimal X and Y coefficients of thermal expansion, owing to the uniform distribution of ceramic particles present throughout the material.

2. RF/Microwave Rogers Advance Laminates

Rogers, a reputable publicly traded firm in the United States, has garnered a reputation for developing innovative solutions and closely collaborating with customers to tackle their challenges. Rogers’ first RT/duroid® material was specifically designed for use in electronic applications in 1949. To date, the RT/duroid® family of high-frequency PTFE laminates is recognized as the market leader in the industry for high-speed RF/microwave PCB design.

Producing circuit boards with optimal reliability often requires the use of specialized equipment and processes. Additionally, a thorough understanding of the material properties is crucial since many materials exhibit varying behavior during PCB processing. Although PTFE-based compounds such as Teflon, a well-known brand name, are used in non-stick cooking pans, their application in PCB manufacture involves unique challenges that require extensive specialized knowledge and expertise.

3. Isola high-performance PCB Laminates

Isola has been a prolific market leader in the development and manufacturing of copper-clad laminate products since 1912. These products are highly sought after in the fabrication of advanced multilayered printed circuit boards (PCBs).

Isola’s products strike the perfect balance between performance and cost, making us a go-to choice for customers seeking high-quality PCB materials.

When selecting a high-speed RF or microwave laminate, designers must consider several factors. These include the dielectric thickness, dielectric constant, dissipation factor, as well as stringent tolerance requirements both within and between batches. For microwave and millimeter wave circuit board designs operating at high frequencies, tight tolerance control on dielectric thickness, trace width, and dielectric constant is essential to achieve optimal performance.

4. Panasonic MEGTRON 6

Panasonic’s MEGTRON 6 is an advanced PCB laminate material designed for high-speed applications such as network equipment, mainframes, IC testers, and high-frequency measuring instruments. Specifically engineered to deliver superior performance, it boasts excellent low dielectric constant and dielectric dissipation parameters, along with low transmission loss and robust heat resistance.

As a leading material supplier in the PCB industry, Panasonic is committed to providing high-quality materials that meet the evolving demands of the market. With a focus on innovation, Panasonic company leverage cutting-edge technologies and processes to develop advanced materials like MEGTRON 6 that help our customers achieve their design goals.

If you require PCB materials that offer exceptional performance, contact us or visit our website to learn more about our product range and how they can help elevate your PCB designs to new heights.

How to Guarantee Copper Clad Laminate Fabrication Quality ?

Manufacturing copper clad laminates requires strict adherence to specific sizing specifications to ensure optimal compatibility with printed circuit board (PCB) designs. Careful attention to dimensions such as length, breadth, warpage, and diagonal deviation is essential to ensure compliance with established criteria.

● The physical performance of copper clad laminates is also critical, with parameters such as dimensional stability, bending strength, peel strength, punching quality, and heat resistance being crucial factors to consider.

● Additionally, thermal stress and Time to delamination (e.g., T300, T288, and T388) must be evaluated alongside other structural considerations.

● Copper clad laminates must also meet rigorous chemical performance requirements, including resistance to chemical reagents, dimensional stability, Z-axis Coefficient of Thermal Expansion (Z-CTE), glass transition temperature (Tg) for mechanical stability, and flammability, among others.

● Electric performance is another important consideration for copper clad laminates, with design requirements aimed at achieving optimal electric performance and meeting necessary PCB standards for factors such as dielectric constant (Dk), volume resistance, dielectric breakdown voltage, Comparative Tracking Index (CTI), electric strength, surface resistance, and dielectric loss tangent (Df), among others.

● A quality copper clad laminate features a smooth, polished appearance without defects such as scratches, dents, bubbles, pinholes, wrinkles, or resin points that could potentially impact the copper clad laminate’s and PCB’s overall performance.

● Lastly, copper clad laminates must meet environmental standards, including eco-emissions and water absorption, among others.

At our company, we are dedicated to delivering high-quality copper clad laminates that meet and exceed industry standards for performance and reliability.

Common Applications of Rigid PCB Copper Clad Laminates

Rigid PCB Copper Clad Laminates are used in many electronic applications that need reliable and robust circuitry. Some common applications are:

● Consumer Electronics: televisions, portable media players, gaming consoles, and other household appliances.

● Medical Devices: medical imaging equipment, heart monitors, pacemakers, and other medical devices.

● Aerospace and Defense: satellites, radars, navigation systems, and other military and aerospace applications.

● Automotive Electronics: electronic control units (ECUs), ABS braking systems, safety features, and other automotive electronics applications.

● Industrial Control Systems: Programmable Logic Controllers (PLCs), motor controllers, and other industrial applications.

● LED Lighting: light emitting diode (LED) lighting fixtures for commercial and residential applications.

● Telecommunications: telecom equipment, mobile phones, and other communication devices.

● Computing and Networking: computer servers, routers, network switches, and other computing and networking equipment.

Selection Criteria for Rigid PCB Copper Clad Laminates

The selection criteria for rigid PCB copper clad laminates depend on the specific requirements of the application. Some common factors to consider when selecting a copper clad laminate for rigid PCBs are:

● The thickness of the copper layer: The thickness of the copper layer on the laminate affects the conductivity, thermal dissipation, and resistance of the circuit board. The thickness of the copper layer must be chosen based on the required electrical performance of the application.

● Dielectric constant: The dielectric constant of the copper clad laminate affects the signal integrity of the circuit board. The higher the dielectric constant, the more signal loss there is, so the dielectric constant of the laminate must be chosen based on the required performance of the application.

● Thermal properties: The thermal properties of the copper clad laminate affect the dissipation of heat generated by the circuit board. The thermal conductivity and Tg (glass transition temperature) of the laminate must be chosen based on the specific thermal requirements of the application.

● Mechanical properties: The mechanical properties of the copper clad laminate affect the reliability and durability of the circuit board. The choices of the type of laminate, its thickness, and the size of the board will be determined by the mechanical and structural requirements of the application.

● Environmental considerations: The ability of the copper clad laminate to withstand environmental factors such as humidity, moisture, and chemicals is critical in some applications.

● Cost: The cost of the copper clad laminates varies depending on the types and characteristics of the laminates. The choice of copper clad laminate will have to be balanced against the required performance of the application and the available budget.

Future Outlook for Rigid PCB CCL

Rigid PCB copper clad laminates are an essential component in modern electronic devices. They provide a reliable and stable foundation for the circuitry inside devices and are widely used in a variety of applications in different industries.

The future outlook for rigid PCBs is bright, as the demand for electronic devices continues to increase. With the constant need for smaller, faster, and more efficient devices, there will be a continued demand for rigid PCBs that can support these advancements.

The increasing demand for eco-friendly and sustainable electronic products is driving the development of new materials and manufacturing processes for rigid PCBs. Manufacturers are exploring new ways to reduce the environmental impact of the production process, such as using organic materials like bamboo instead of fiberglass.

Summary

PCB manufacturing with types of CCL in JarnisTech

This informative article discusses copper-clad laminate, including its types, classification, and selection criteria. As a leading PCB and PCB assembly manufacturer in China, JarnisTech has accumulated over 20 years of industry experience and is renowned for producing high-quality quick-turn PCB prototypes, small and medium volume PCBs, and PCB assembly services.

Our unwavering commitment to excellence is reflected in our adherence to the highest standards of PCB fabrication and assembly. We prioritize delivering top-of-the-line printed circuit boards fabricated using superior quality copper-clad laminates.

If you have any inquiries or require further information about our services, please do not hesitate to contact us via [email protected]. Our team remains dedicated to responding to your queries promptly and providing unparalleled customer service.

Related Posts:

1. Selecting PCB Laminate Materials: A Comprehensive Overview

2. PCB Copper Trace Width and Space: Everything You Need to Know About Them

3. Which Types are Most Commonly Used in PCB Substrates?

4. What Is Fiberglass PCB and Why Fiberglass Used in PCB Manufacturing?

5. Standard PCB Thickness-Choosing the Correct Thickness for PCB

6. Why FR4 Material Is Commonly Used in PCB Fabrication?

7. Glass Epoxy and Its role in PCB Manufacturing

8.Epoxy Resin Used For CCL in PCB Manufacturing Why So Important?